- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Processing> Introduction of heat energy conversion during drying and cooling of pet feed

Introduction of heat energy conversion during drying and cooling of pet feed

2021-01-22 17:30:34Materials with higher moisture content will evaporate by absorbing the heat in the drying medium through the action of the drying medium in the dryer. At the same time, the temperature of the drying medium itself is reduced due to the release of heat, and the moisture evaporated from the material is discharged from the drying system along with the flow of the drying medium.

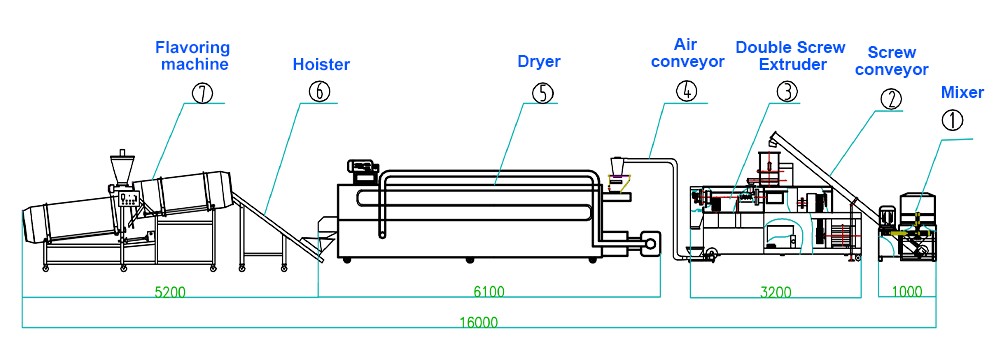

In the feed production process, the products coming out of the extruder and pelletizer must be dried or cooled by certain equipment before they can be packaged, stored or sold. Therefore, drying and cooling are indispensable links in the processing of these products. The heat energy conversion and utilization in this process are briefly introduced as follows:

image

1. Heat energy conversion during drying

Materials with higher moisture content will evaporate by absorbing the heat in the drying medium through the action of the drying medium in the dryer. At the same time, the temperature of the drying medium itself is reduced due to the release of heat, and the moisture evaporated from the material is discharged from the drying system along with the flow of the drying medium. The replenishing drying medium absorbs the heat released by the steam in the heat exchanger and increases in temperature. At the same time, the steam becomes condensed water and is discharged from the heating system.

2. Thermal energy conversion during cooling

Compared with the drying process, the clean air in the natural state is used as the medium in the cooling process, and the material with a certain temperature and moisture is cooled and dehumidified.

Take the commonly used countercurrent particle cooler as an example: in the cooler, the material flows from top to bottom, and the cooling air flows from bottom to top, forming a countercurrent flow with the material. The material in the lower part provides the heat required for moisture evaporation and air temperature rise in the top-down process, and the temperature is close to the ambient temperature. As the upper air absorbs the heat released by the particles during the bottom-up travel process, the temperature and moisture capacity are increased. Therefore, the purpose of cooling and dehumidifying the feed pellets is realized. The hot and humid air after work is discharged from the cooling system by the cooling fan.

3. Drying and cooling integrated machine

Usually on some specific occasions, when the material production process permits, sometimes we will realize the drying and cooling process of the material through a drying and cooling integrated machine.

The mechanism of the drying and cooling process in the integrated drying and cooling machine is basically the same as the above. However, there will be some differences in the process and effect of drying and cooling with the different configuration of the wind path.

4. The thermal energy conversion in the stabilizer

For some special materials, such as shrimp material, the degree of maturation is relatively high. After being extruded, it still needs a period of time for further heat preservation and heating. This process is usually carried out in a stabilizer.

Generally, the stabilizer is made into a jacket type, and a certain number of steam pipes are arranged in the cavity to keep the temperature in the cavity stable at about 100°C, so that the material is further matured and stabilized.

In this process, steam is continuously consumed, and the heat energy of the steam is continuously transferred to the material through the pipe wall, which increases the temperature of the material and matures.

Pet Food Extruder Machine

Pet Food Extruder Machine Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines