All Categories

View All >-

Dry pasta production line

Dry pasta production line

-

As the professional automatic dry pasta production line, we improve the performance of the macaroni production line .The pasta manufacturing plant uses...

-

Instant noodle production line

Instant noodle production line

-

We specialize in the production of instant noodle processing line .The noodles size made by our instant noodle production line can be square or round,net...

-

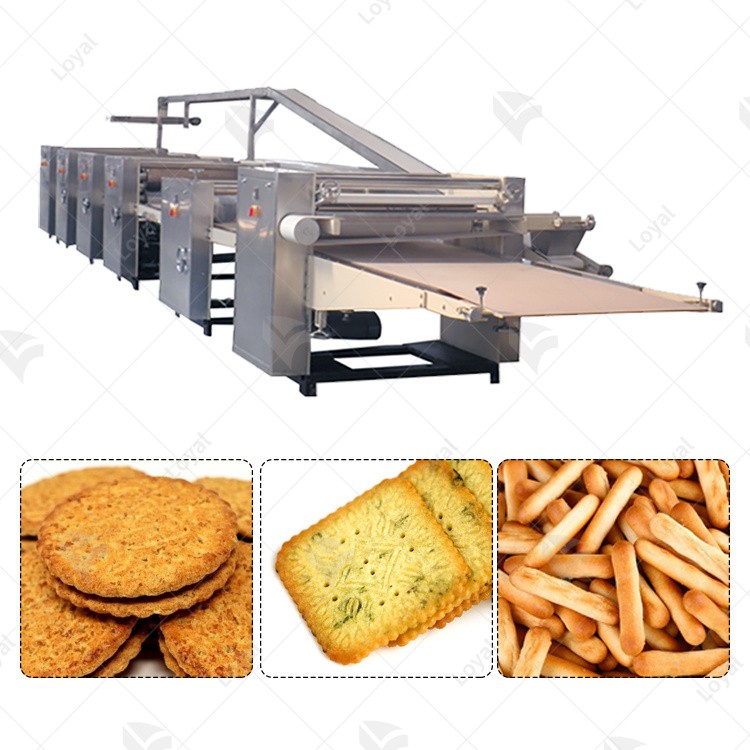

Automatic Biscuit Production Line

Automatic Biscuit Production Line

-

Industrial Automatic Biscuit Production Line is making quality soft and hard biscuit ,from material mixing to finished products one time...

-

Japanese panko bread crumbs making machine

Japanese panko bread crumbs making machine

-

How Are Panko Crumbs Made?

This panko breadcrumbs Processing line integrates a series of advanced processing equipment and...

Featured Products

Our Manufacturer with main products: Macaroni Production Machine, Instant Noodle Machine, Biscuit Making Machine

-

Automatic macaroni making machine

Automatic macaroni making machine

-

The pasta manufacturing equipment uses barley flour, wheat flour, potato starch, corn starch, etc. as the main raw materials, from flour to finished...

-

Instant Pasta Production Line

Instant Pasta Production Line

-

Overview of Instant Pasta Production Line

In today's fast-paced world, convenience is paramount, especially in the realm of food consumption....

-

Automatic Biscuit Production Line

Automatic Biscuit Production Line

-

Industrial Automatic Biscuit Production Line is making quality soft and hard biscuit ,from material mixing to finished products one time...

-

Twin Screw Food Extruder Machine

Twin Screw Food Extruder Machine

-

Twin Screw Extruder process developed by twin screw extruder manufacturers more then 30 years, enables the continuous production of highly...

-

Automatic Small Protein Bar Machine

Automatic Small Protein Bar Machine

-

Protein bar machine has all automatic continue technologic, high production advanced technology. Coordinate with the chocolate spray...

-

Fish Feed Making Machine

Fish Feed Making Machine

-

The fish feed making machine was designed to make fish feed,pet feed,and other animal feed,it was taking meat meal, fish meal, bone...

-

Corn Puff Snacks Making Machine

Corn Puff Snacks Making Machine

-

Corn Puff Snacks Making Machine is used for making various of puff snacks, corn puffs,chocolate filled bar,cream filled pillow, bread snacks and so on....

-

Fried Instant Noodles Production Line 500000 Bags

Fried Instant Noodles Production Line 500000 Bags

-

Instant noodles production line with perfect technology, compact structure, original design and stable performance, is developed on the base of...

-

Instant noodle processing line 300000 Bags

Instant noodle processing line 300000 Bags

-

Instant noodle processing line is the production of new generation which developed based on similar productions from overseas and domestic...

-

Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines

-

Fully Automatic Biscuit Making Machine can make many different type of biscuits. Such as cream biscuit, sandwiching biscuit,soda cracker...

-

Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line

-

Bread crumbs are widely used food additives, mainly used for western fried steaks, fried chicken legs and other frying accessories. According to...

-

Cereal Bar Production Line

Cereal Bar Production Line

-

Cereal bars are made of oats, rice, nuts, dried fruits and other main ingredients. It is popular in the market because of delicious taste,...

WHY CHOOSE US

- All about usOur aim is to provide you with the tour service of the top quality, and we'll d o our

- Contact detailsOur aim is to provide you with the tour service of the top quality

- Quality Controlcotton bedding sets ,bamboo pillows ,bamboo blankets ,polyester quilts

Food Processing Technology Principles And Practice

Everything You Need To Know About Cookie Production Line

Production Line Introduction Fully Automatic Cookie Production Line : Equipped with advanced technology, featuring a state-of-the-art LCD touch panel and PLC intelligent control, it...

Curry Powder Microwave Drying Sterilization Machine

Introduction The microwave chili powder sterilization equipment is suitable for the drying and sterilization of spice and spice powder. It has a fast sterilization speed, does...