- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home>Products>Food Extruder Machine>Twin Screw Food Extruder Machine

Twin Screw Food Extruder Machine

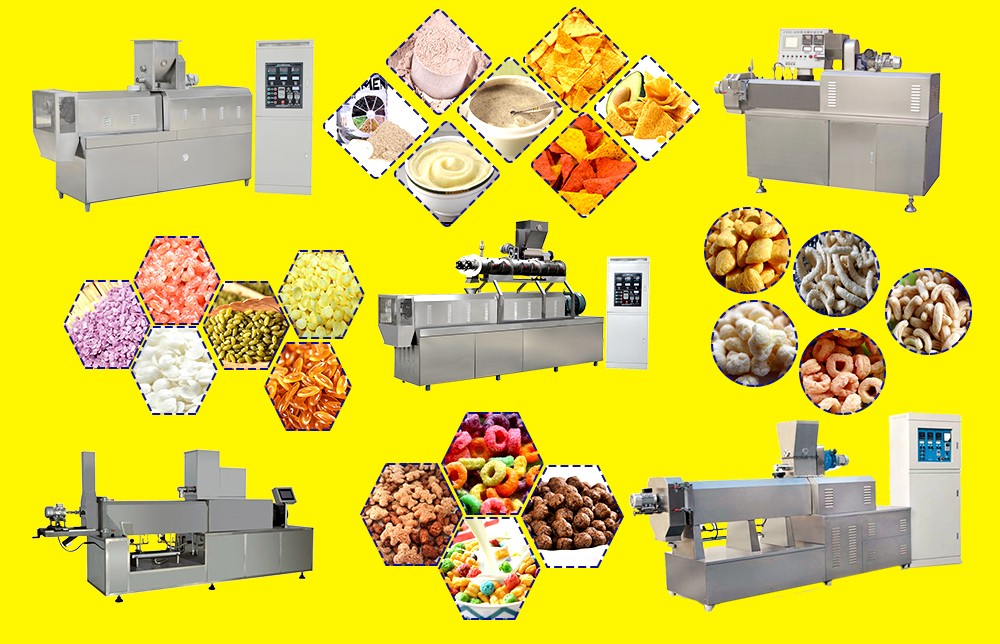

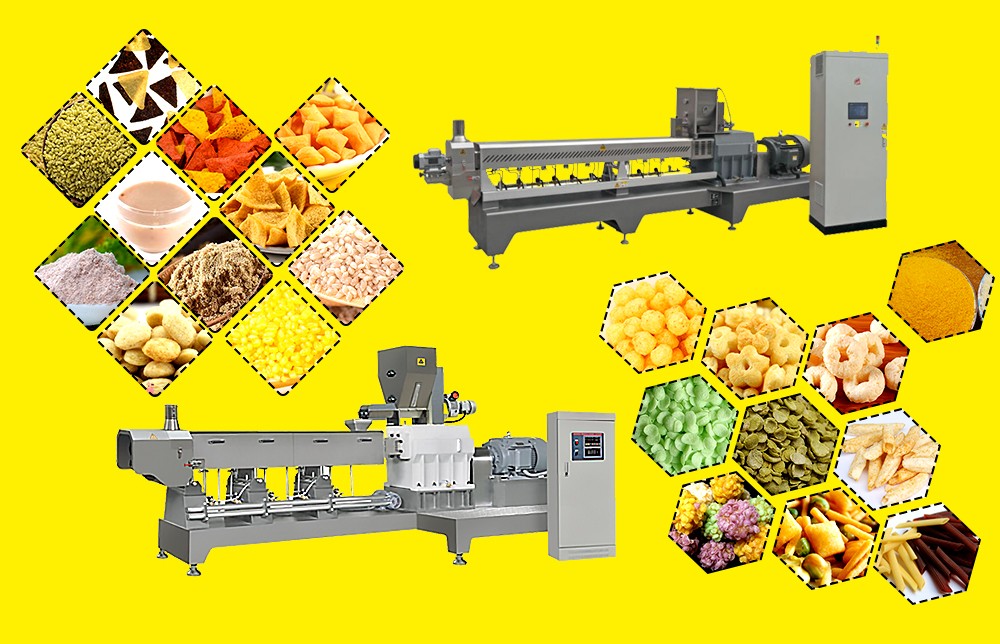

As a twin Screw extruder machine manufacturer , Due to a wide range of extruder screws and barrels design, a double screw extruder technology is able to ensure food extruder machine manufacturing process to produce a wide range of Food & Feed products, making puffs snacks, pet food, fish feed, corn flakes, breakfast cereals, TVP, artificial rice for sale.

- Loyal

- Twin Screw Extruder

- Shandong China

- CE,ISO9001,SGS,BV

- 1 set/twin screw extruder

- Contact Us

- Wooden case or wooden pellets depended on clients' requirement

- 30 working days

- T/T,L/C,D/P

- 30days /twin screw extrusion machine

Twin Screw Food Extruder Machine Details

| Applicable Industries | Twin-screw extrusion processing versus conventional food processing | Capacity | 100-150g/h 200-250kg/h 300-500kg/h 300-500kg/h 800-1000kg/h | Condition | New |

| Converter | Customizable | Equipment Material | Stainless Steel/Carbon Steel | Food processing machinery manufacturers | Loyal Factory |

| Function | Multifunction | HS Code | 84388000 | Installation | Engineer Guide |

| Key Selling Points | Competitive Price | Key Words | Twin screw Extruder | Machinery Test Report | Provided |

| Model | LY65 LY70 LY85 LY75 LY95 | Place of Origin | Shandong, China | Processing Types | snacks extruder food processing |

| Voltage | customizable |

Twin Screw Food Extruder Machine Description

Twin Screw Extruder process developed by twin screw extruder manufacturers more then 30 years, enables the continuous production of highly homogeneous and finely structured products, using bio-sourced or synthetic raw materials. It is used to produce a wide range of Food & Feed products, our multifunctional food extruder machine offer flexible, reliable processing for your breakfast cereals, food ingredients, pet food and aqua feed products.

twin screw extruder manufacturers

Technical Parameters OF TWIN SCREW food extruder MACHINE FOR SALE

|

DIFFERENT MODEL OF ORDINARY TWIN SCREW EXTRUDER FOR SALE |

||||

|

Model |

Installed Power |

Power Consumption |

Output |

Size (L*W*H) |

|

LY65 |

47KW |

30KW |

180kg/h |

3500x950x1850mm |

|

LY70 |

53KW |

37KW |

200-250kg/h |

3200x760x2000mm |

|

LY70L |

53KW |

37KW |

200-250kg/h |

3200*930*2000mm |

|

LY85 |

99KW |

75KW |

500kg/h |

3800*1100*2350mm |

|

Applied Products:Pet food\ nutrition rice\ puff snacks\doritos chips

Applied Products |

||||

|

MULTIFUNCTIONAL STANDARD SCREW EXTRUDER MACHINE FOR SALE |

||||

|

LY75 |

98KW |

75kw |

200-500kg/h |

5200*1100*2800mm |

|

LY95 |

142kw |

110KW |

600-1200kg/h |

6400*3000*3000 |

|

Applied Products:Pellets snacks,Puffs snacks,Pet Food,Fish Feed,Corn Flakes, Breakfast Cereals, TVP, Artificial rice etc

|

||||

SCREW L/D RATIO

| The molel of double screw extruder machine | ||||

|

MODEL |

LY65 |

LY70 |

LY 70L |

LY85 |

|

Cooling system |

WITHOUT |

WITHOUT |

WITH |

CUSTONIZABLE |

|

L/D |

1050/₵65 |

1408/₵70 |

1408/₵70 |

1900/₵85 |

How does the double screw extruder machine work?

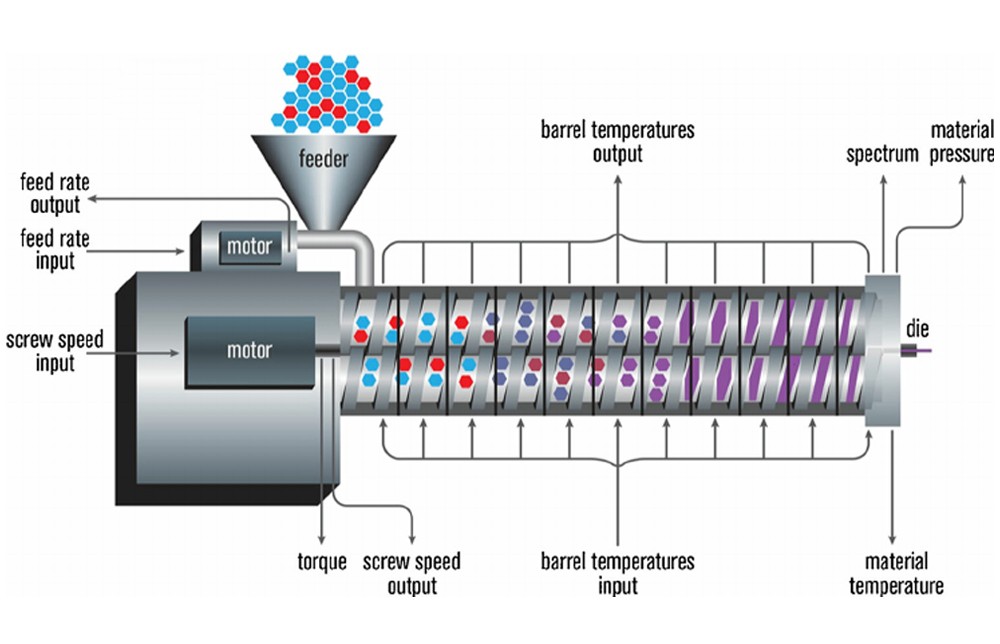

Twin screw extruders consist of two intermeshing, co-rotating screws mounted on splined shafts in barrel. Due to a wide range of screw and barrel designs, various screw profiles and process functions can be set up according to process requirements. Hence, a double screw extruder technology is able to ensure transporting, compressing, mixing, cooking, shearing, heating, cooling, pumping, shaping, etc. with high level of flexibility. The major advantage of intermeshing co-rotating twin screw extruders is their remarkable mixing capability which confers exceptional characteristics to extruded products .

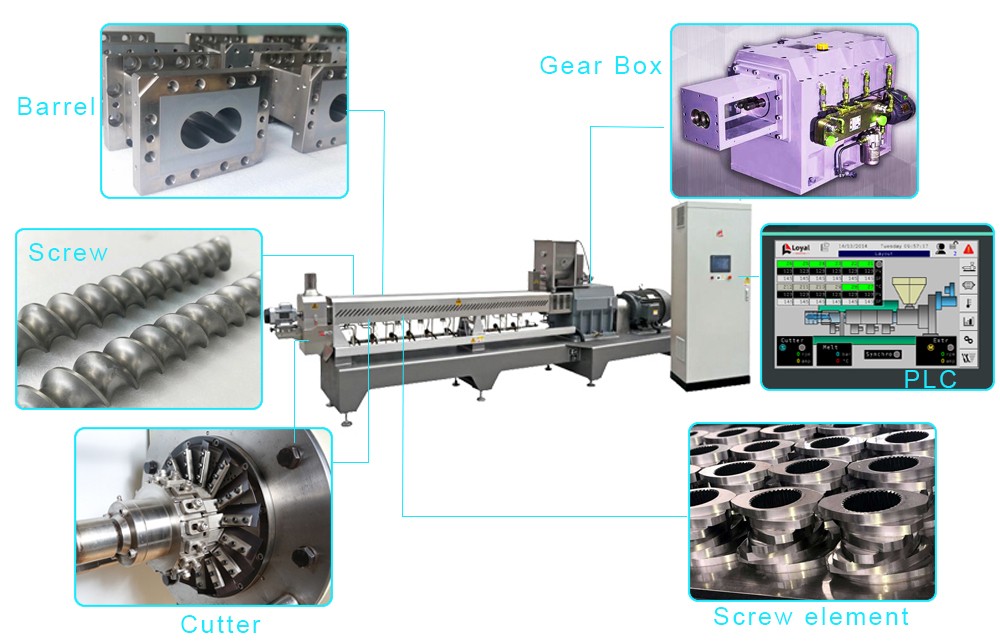

The detail of double screw extruder

|

Application for Twin Screw Extrusion |

||||

|

|

|

|

|

|

|

Puffed Snacks |

Cereals Snacks |

Chips Food |

Pet Food |

Aquafeed |

|

-Direct expanded snacks -Nutrition baby powder -Core Filled Snacks -Bread Snack/Flat Crispy Bread -Modified flours and starches -Bread crumbs -Texturized proteins -Artificial rice |

- Breakfast cereals -Corn Flakes -Baby Food |

-Multigrain Corn chips -Doritos chips -Rice Cracker -Corn chips |

-Foods for small pet -Bird food -Multicolor Food -Dog food -Semi-moist pet food |

– Micropellets – Floating feeds – Sinking feeds – Shrimp pellets |

Q: Whether our food extruder machine recipt can process your material?

|

A: Our double screw extruder mainly used in following application with different snacks: |

|

Applied Products |

|

Main Ingredients: Wheat Flour, Corn Flour, Potato Flour, Rice Flour, bran, multi-grains powder,Corn Starch,Wheat Starch |

INTRODUCTION OF twin screw extruder machine FROM food processing machinery manufacturers:

|

Main Features Of Twin Screw Food Extruder Machine |

|

|

1 |

Series of double-screw extruder mainly consist of feeding system, extruding system, cutting system, heating system, lubricating system and controlling system. |

|

2 |

Transfer mixed raw materials from Mixer to co rotating twin screw extrusion |

|

3 |

Automatic lubricating and forced cooling make sure that twin extruder machine performs safely and extends using life. Feeding system, extruding system and cutting system all adopt frequency conversion timing to gain powerful drive, stable perform, and electricity saving. |

|

4 |

Screw are made of alloy and processed by special technique to possess high intensity, abrasion resistant and longer using life. |

|

5 |

By means of designing different structures and slenderness ratios according to needs of products, screw extruding system can meet different technology demands. |

The detail of double screw extruder

THE ADVANTAGES OF TWIN SCREW EXTRUSION

|

Extruders has become the standard over time in several industries because it offers numerous advantages |

|

--- More consistency in production and control of product quality |

|

-- Increased productivity due to continuous processing, faster start up and shut down between product changes, quick changeover and advanced automation |

|

--- Greater flexibility, with the capability to process a wide range of raw materials |

|

--- Optimized footprint thanks to energy and water savings |

|

--- Simple and easy to maintain and clean |

Comparing with single screw extruder AND twin screw extruder

| Comparing with single screw extruder AND twin screw extruder | ||

|

Performance |

Single Screw Extruer |

Co-rotation Twin Screw Extruded machine |

|

Conveying Efficiency |

Low |

High |

|

Compounding Ability |

Low |

High |

|

Shear Effect |

Medium |

High |

|

Energy consumption |

High |

Lower |

|

Self-cleaning |

Low |

High |

|

Calorific Value |

High |

High |

|

Stay Time |

Long |

Short |

|

Material feeding |

Difficult |

Easy |

DOUBLE SCREW EXTRUDER

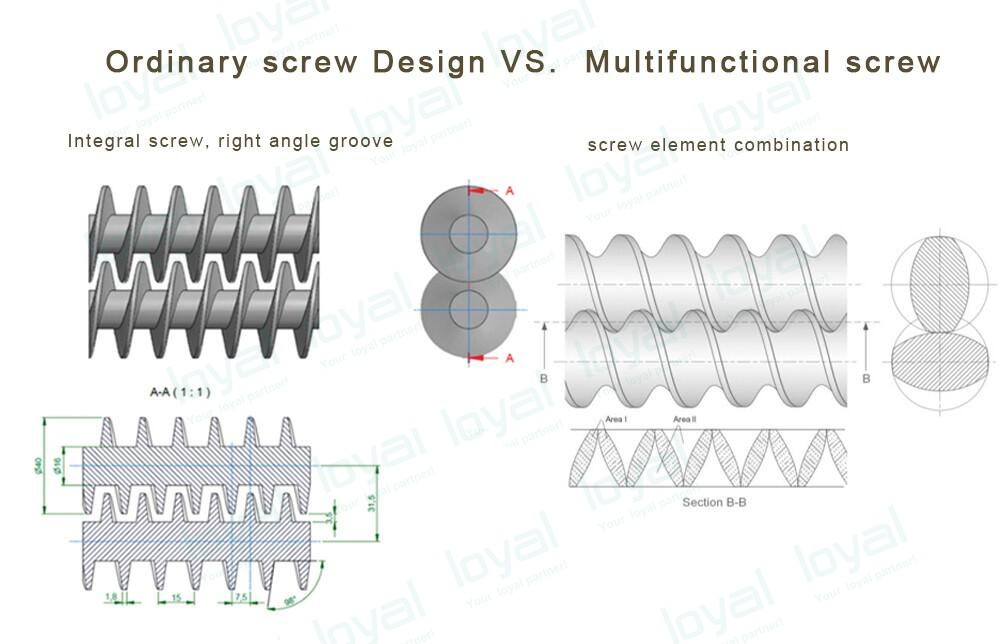

ordinary twin-screw extruder Design VS. Multifunctional co-rotating twin-screw extruders DESIGN

| ordinary twin-screw extruder Design VS. Multifunctional co-rotating twin-screw extruders DESIGN | |

|

ordinary twin-screw extruder(TSE) |

Multifunctional standard extruder(MSE) |

|

The screw is an integral screw and can’t be freely combined. Different products need to be replaced with different types of screws |

twin screw extruder design can also more effectively change the screw element combination and different accurate metering feeding hopper for various material compounding.

|

|

Mixing capability of ordinary twin- screw extruders is very limited, and any flow restrictions to enhance mixing through special screw designs lead to depress the extruder throughput. |

Remarkable mixing capability, due to the interpenetration of the screws and the broad diversity of specialized screw designs (such as reverse screw elements, kneading blocks, gear mixing elements, etc.) which allow the extent of shearing/mixing to be precisely adjusted; hence leading to control the degree of mixing in regards to mixing intensity and mixing quality (dispersive versus distributive). |

|

Button control

|

PLC control Better control of process parameters, that are: narrower residence time distribution, lower dispersion of shear rates and strain, higher convective heat transfer, accurate control of temperature profile; hence leading to much better control of shear-time-temperature histories in the extruder, to much wider range of mechanical energy inputs, and so to more consistency in regards to material conversion and product quality. |

|

The V-belt drives the cutter to run, and the wear rate is high |

– Cutter with lateral movement, Highly flexible cutter The cutter can be moved to one side for easier control, access and cleaning. |

|

WITHOUT |

- intelligent recipe memory In order to guarantee an end product of consistent quality, the extruder system is equipped with an intelligent recipe memory. This offers two significant benefits: the susceptibility to process errors decreases, and production can be quickly adapted to other recipes. |

Detail of double screw

extruder screw design for screw elements twin screw extruder

Ordinary screw Design VS. Multifunctional screw elements

Ordinary screw Design VS. Multifunctional screw elements

Screw Elements:

1. Supper anti-abrasive and anti-corrosion

2.. Raw material is heating treatment and overall hardening, high wear-resistance and toughness.

3. Special heat treatment and high precision CNC machining. Make sure to get the best quality.

- Suitable for your high protein materials

Different screw elements combination use for different function material compounding, Our lists of screw elements are including the following:

--Conveying elements

--Conveying elements

--Reverse elements

--Compression elements

--Discharge elements

--Kneading blocks and single mixing discs or paddles

Detail of double screw

Extruder Barrel:

Extruder barrel is made with bushing and cylinder, bimetallic treatment.

The screw and barrel of double screw extruder machine adopt segmented design. Different combination of barrel decide the extruder L/D; different combination of screw decide the extruder function.

Detail of double screw

2021 Customer Order Dog Food Manufacturing Process Line Form:

Our dog food making machine is summed up by a number of 25 technical engineers who have more than ten years of experience. Loyal wet pet food extruder production line has a number of pet food project technology patents, which can provide you with the most detailed formula and process documents, which can save dog food production line costs while improving good development in the pet food manufacturing industry.

|

Pet Food Manufacturing Process Line Purchased By Customers Producing Dog Food Products |

|

|

1 |

Chine 300T/Month Industrial Wet Dog Food Production Line |

|

2 |

1T/H Tough Dog Food Production Line For Sale In Puerto Rico |

|

3 |

1T/H Crisp Dog Cat Food Production Line For Sale In Bolivia |

|

4 |

Senegal 1T/H Industrial Dog Food Extrusion Machine |

|

5 |

1T/H Dog Food Machine For Sale In Côte d'Ivoire |

|

6 |

1T/H Industrial Dog Food Equipments Sold In Russia |

|

Old Customers Repurchase Dog Food Manufacturing Process Line In 2021 |

|

|

7 |

1T/H Industrial Dog Food Production Line For Sale In Uzbekistan |

|

8 |

1000kg/h Industrial Automatic Dog Food Machine For Sale In Senegal |

|

9 |

Mozambique 1T/H Industrial Dog Food Manufacturing Line |

|

10 |

Bangladesh 2T/h Industrial Dog Pet Food Making Machine |

|

11 |

1T/H Thai Dog Food Production Line |

|

12 |

Uzbekistan 1T/H Dog Food Production Line |

|

Customers Who Buy Dog Food Production Line Through An Agents |

|

|

13 |

USA 1T/H Pet Food Production Line |

|

14 |

800kh/h Industrial Wet Dog Food Production Line For Sale In Nigeria |

|

15 |

Algerian Dog And Cat Food 300kg/h Production Line |

|

16 |

Sudan 200kg/h Wet Dog Food Making Machine |

|

17 |

Moldova Small 200kg/h Wet Dog Food Production Line |

|

18 |

200kg/h Milk Dog Food Machine Sold In Ukraine |

|

Customers Who Are Building Factories Buy Dog Food Extrusion Machine: |

|

|

19 |

Nigeria 150Kg/H Industrial Wet Dog Bone Food Making Machine |

|

20 |

Austria Sells Industrial Dog Food Machine 100kg/h |

|

21 |

Nigeria 150Kg/H Dog Food Making Machinery |

|

22 |

Vegetable Dog Food Making Machine For Sale In Pakistan 100kg/h |

|

23 |

Austria Sells Industrial Dog Food Machine 100kg/h |

|

24 |

50Kg/H Small Dog Food Extrusion Machine For Sale In Botswana |

|

25 |

Sudan 50kg/h Small Dog Food Production Line |

|

26 |

Algerian Dog Food 300kg/h Production Line |

Related Processing

| Single Screw VS Twin Screw Extruder |

| Producing Textured Soy Protein By Twin-Screw Extruder |

Product Categories

- Macaroni Production Machine

- Instant Noodle Machine

- Biscuit Making Machine

- Nutrition Bar Manufacturing Equipment

- Bread Crumb Machine

- Food Extruder Machine

- Corn Flakes Production Line

- Corn Puff Snacks Production Line

- Nutritional Baby Rice Powder Food Machine

- Dog Food Manufacturing Equipment

- Feed Production Line

- Cold Pressed Pet Food Machine

- Soya Nuggets Extruder

- Artificial Rice Production Line

- Doritos chips making machine

- Pellet Snack Making Machine

- Modified Starch Machine

- Kurkure Manufacturing Machine

- Industrial Microwave Oven

- Fried Dough Extruder Machine

- Industrial Deep Fat Fryer

- Wafer Line

- Automatic Packaging Machine

Contact Us

- Shandong Loyal Industrial Co.,Ltd.

- Telephone+86 13256674591

- Email[email protected]

- WhatsApp+86 13256674591

- WeChat13256674591

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -The Qihe Yellow River Material Warehouse, No. 689, Meili North Road, Jinan City, Shandong Prov

Pet Food Extruder Machine

Pet Food Extruder Machine Single Screw Extruder Food Processing Machine

Single Screw Extruder Food Processing Machine Twin Screw Food Extruder Machine

Twin Screw Food Extruder Machine