- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Pellet Snack Making Machine

Contact Now-

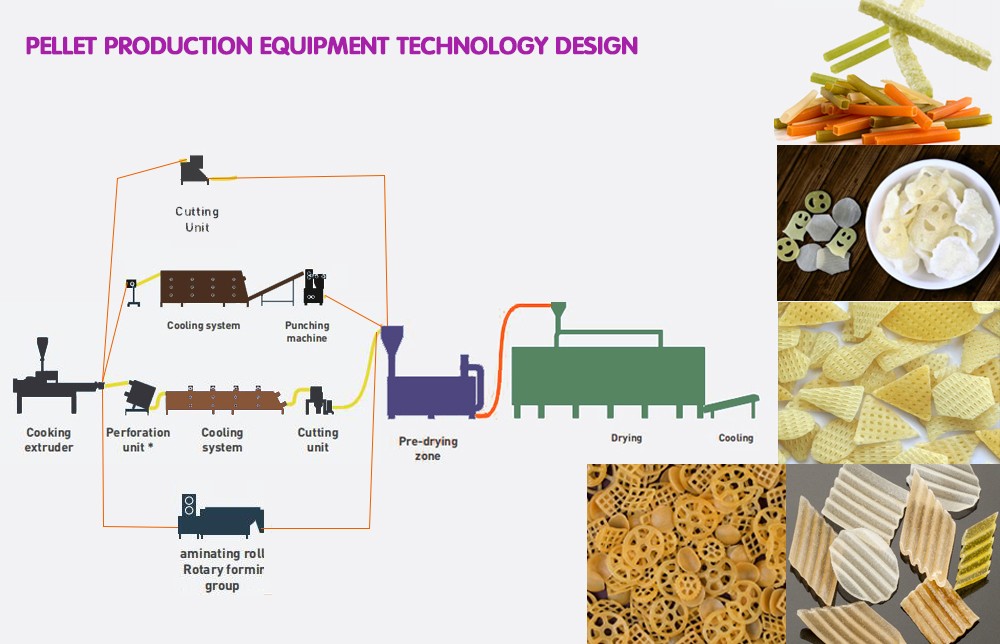

Snack Pellet Production Lines

-

For the snack pellet production lines before we always use single screw extruder. The single screw extruder food processing is raw material is kneaded under high pressure and cooked by the...

The Snack Pellet Manufacturing Process

Whats snack does pellet snack production line can make?

3d,2d pellet snack can be made by pellet snack prodcution line. suach as shell, screw, spiral, square tube, circle tube shape.

Main Features Of Pellet Snack Production Line

1) Simple structure in linear type ,easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

4. SIEMENS(China) motors are used, ensure the excellent performance of machines.

5. Cooper Pipes used for cooling cylinder, they are quite durable than plastic rubber pipes.

6. Food Grade stainless steel made Cutter cover meet strict food process safety requirements.

How extruded snacks pellets are made?

Pellet snacks are produced dried and semi-processed for easy storage and shipment and in a second phase are expanded, seasoned and packed.

(1) Raw Material: Cassava Starch, Potato Starch, Potato Powder, Corn Starch, Wheat Flour, Etc

(2) Product Can Make In Shaping Machine: 3d Pellet, Net Pellet, Bat Shape, Round, Oval, Hexagonal, Square, Triangular, Etc.

How are snack pellets made?

Snack pellets are high-density and expandable intermediate products that are manufactured through extrusion using raw materials such as potato, corn, tapioca, rice, legumes and other cereals and vegetables

Snack pellets are a ‘semi’ finished ingredient which means that once produced by us, they are ready for our customers to manufacture into their finished innovative products.

The Automatic 2D And 3D Snacks Fryums Pellet Making line of snack pellet extruder

Mixer→Screw conveyor→Single screw extruder→Cutter→Vibrating feeder→Hoister→Dryer→Cooling machine

|

The Snack Pellet Manufacturing Process Of Pellet Snack Making Machine |

|

|

Pellet Manufacturing Equipment |

Technical Parameter |

|

Pellet Making Process Flour Mixer |

Model: Dc-Bfj |

|

Installed Voltage:380v / 50hz |

|

|

Power Consumption:4kw |

|

|

Installed Power:4kw |

|

|

Capacity: 15-20kg/5-8mins |

|

|

Dimension: 700*600*1200 Mm |

|

|

Motor Band: Lijiu Made In China |

|

|

Material: Stainless Steel 201 |

|

|

Function: Mixing The Raw Materials |

|

|

Screw Conveyor (Snack Pellet Extruder ) |

Model:Ly-Sh |

|

Input Voltage:380v/50hz |

|

|

Installed Capacity:1.5kw |

|

|

Power Consumption:1.5kw |

|

|

Output:100-300kg/H |

|

|

Size:2.0×0.8×2.05m |

|

|

Function:Screw Conveyor Can Not Only Convey On The Level But Also By Any Angel These Materials Can Be Conveyed In The Stainless Steel Roller Without Leaking, Dust Pollution; Meanwhile It Can Send The Self-Mixer To The Feeding Machine Or The Conditioner And Directly Send The Discharge Hole Of The Inflating Extruder. |

|

|

Ly3000-100 Single Screw Snack Pellet Extruder With Cooling System |

Capacity: 80~100kg/H |

|

Model: Ly3000-100 |

|

|

Capacity:80-120kg/H |

|

|

Heating Power:46kw |

|

|

Feed Motor:0.75kw Frequency |

|

|

Cutting Motor:0.75kw Frequency |

|

|

Screws Material:38crmoal/38 |

|

|

Screw Diameter:100mm |

|

|

Barrel Material:45#Customize Steel |

|

|

Dimension: |

|

|

Function: Extruding The Mixture Into Different Shapes(This Machine Uses Different Die Can Produce Different Shape Product) |

|

|

Function: Extruding The Mixture Into Different Shapes(This Machine Uses Different Die Can Produce Different Shape Product |

|

|

Punching Machine |

Power:0.75kw |

|

Dimension:1100×800×1200mm |

|

|

Material: Sus304 /Alloy Steel |

|

|

Purpose : Punch The Product |

|

|

|

|

|

Pellet Forming Machine For 3d |

Power :1.1kw |

|

Dimension :1200*900*1100mm |

|

|

Material: Sus304 /Alloy Steel |

|

|

Purpose : Shaping And Cutting |

|

|

Extra Shaping Roller |

|

|

Vibrate Feeder |

Power:-1.5kw |

|

Capacity:-300kg/H |

|

|

Size:-1800*500*700mm |

|

|

It Can Continuously And Evenly Feed The Snacks Equipment |

|

|

It Is A Indispensable High-Efficiency And Energy-Saving Equipment In The Snacks Production Line. |

|

|

Cooling The Pellets To Avoid Them Sticky |

|

|

Cooling Conveyor |

Cooling Power: 0.15kw |

|

Function: Used Convey& Cooling Pellet Sheets Before Go To Cutting. |

|

|

Snack Pellets Manufacturing Process Hoister |

Power:0.37kw |

|

Dimension:2470*600*2000mm |

|

|

Material: Pvc / Sus201 |

|

|

Drying Roller |

Power :13.5kw |

|

Dimension:2850x750x1850mm |

|

|

Material: Sus304 / Sus201 |

|

|

Ltd-5d 5 Layer Drying Machine (Snack Pellets Manufacturing Process) |

Driving: 0.75kw+1.1kw |

|

Burner Brand: Italy Baltur |

|

|

Fuel Consumption: |

|

|

Btg-15 : 5-16m³/H |

|

|

Dimension: 7100*1200*2000mm |

|

|

Cooling Conveyor |

Driving: 0.75kw, |

|

Dimension:4000x900x700mm, |

|

|

4sets Blowers |

|

|

Snack Pellets Manufacturing Process Vibrate Feeder |

Power :0.24kw*2 |

|

Dimension: 1100x650x800mm |

|

|

Function:- Conveying Snacks To |

|

|

Next Machine |

|

|

Continuous Fryer Machine |

Heating Power: Gas |

|

Capacity: 100-300kg/H |

|

|

Frying Time: 10-30 Seconds, According To Product Situation. |

|

|

Dimension: 3000*1000*2100mm |

|

|

Valid Frying Width:650mm |

|

|

Belt:Ss304 |

|

|

Motor: Siemens |

|

|

Features: |

|

|

Double Conveyor Belt, Belt Speed Adjustable By Inverter |

|

|

Frying Temperture Adjustable |

|

|

Burner |

Btg 20cn: 6-20.5m³/H |

|

Btl 20cn: 10-22kg/H |

|

|

Hot Oil Pump |

Model:Ry40-25-160 |

|

Flow: 10 M³, Range:28m, Power: 2.2kw |

|

|

Power Supply: 3ph 380v,50hz, Single Phase:220v,50hz |

|

|

|

|

|

Hot Water Recirculating Pump |

Pump |

|

For Oil Circulation Use |

|

|

Model:Ry80-50-200 |

|

|

Flow: 40 M³, Range:32m, Power: 7.5kw |

|

|

Power Supply: 3ph 380v,50hz, Single Phase:220v,50hz |

|

|

Oil Tank 1000l (New Oil) (Optional) |

1. Use In: It Is Used For Storage Frying Oil When Cleaning And Preheat The Oil , When Oil Less Adding Oil Into The Fryer While Working At Any Time. |

|

2. Material Quality: Stainless Steel , Stainless Steel Electric Heating Tube |

|

|

Dimensions: 1200*1200*2100mm |

|

|

Effective Size: 1000*1200mm |

|

|

Thermal Power Rate: 5kw |

|

|

Capacity: 1 Cubic Meter |

|

|

In And Out Pipe Diameter: 1 Inch |

|

|

Oil Filter |

Oil Filter Machine |

|

Drum Power: 0.12 Kw (Main Motor) |

|

|

Fan Motor: 1.3 Kw (Air Blower) |

|

|

Including Flow Of Pump:10m³/H(2.2kw) |

|

|

Dimension: 1350*1100*1500 Mm |

|

|

Installation Material(Tube, Valve)(Optional) |

Connection |

|

1. Flange+Ball Valves+Pipes |

|

|

|

|

|

Vibrate De-Oiling Machine |

1. Use In: Remove Excess Oil Of Pellet |

|

2. Material Quality: Food Contacting Parts Stainless Steel |

|

|

3. Continuous Working |

|

|

Power: 0.2 Kw*2=0.4 Kw(2 Vibrate Motor) |

|

|

Dimension: 1950*850*900 Mm |

|

|

Food Grade Pvc Hoister |

Usage:Deliver The Snack To Next Device. |

|

Working Together With The Flavoring Drum. |

|

|

Food Grade Pvc,Stainless Steel. |

|

|

Hoister Power:0.37kw |

|

|

|

|

|

Rolling Flavoring Machine |

Model :Dc-Ii |

|

Power:0.75kw |

|

|

Motor:0.37kw |

|

|

Length:2100mm |

|

|

Size:2.1×0.6×1.8m |

|

|

Capacity:100-200kg/H |

|

|

Function: Spray Seasoning Oil And Powder Onto The Snacks So As To Make The Snacks Tasteful. |

|

|

Seasoning Podwer Machine For Pellet Making Process |

Model :Dc-Ii |

|

Power:0.37kw |

|

|

Feeding Hopper Volume :10kg |

|

|

Size:0.7×0.4×0.6m |

|

|

Capacity:0.7×0.4×0.4m |

|

|

Cooling Machine For Pellet Snack Making Machine |

Model: Lyc |

|

Driving: 0.75kw, |

|

|

Dimension:4000x900x700mm, |

|

|

4 Sets Blowers |

|

Snack Pellets Manufacturing Process

- How Does The Utilization Rate Of Extruded Floating Fish Feed Compare With Powder And Pellets? +

- Expanded floating fish feed is beneficial to improve feed utilization Due to the high temperature and high pressure processing conditions, the starch in the feed is matured, fat, etc. are more conducive to digestion and absorption. It also...

- From hard pellets to puffed materials Is it the development of the feed industry or the transformation of the aquatic industry? +

- What is an extruder? Puffed feed, also known as cooked feed, is a new type of feed processed by puffing technology. After the raw materials are puffed, they form a "popcorn" state, which not only changes the physical state such as the shape,...

Pellet Snack Making Machine Video

- The role of Snack Pellet Production Lines +

- Introduction of fried pellet snack food machine The fried pellet snack food machine adopts the flour, starch, and potato starch as the material then forms a kind of leisure food after extruding, slaking, forming, drying, frying and...

Food Pellet Making Machine News

- How do you make pellet feed? +

- Pellet feed is one of compound feed products, a pelleted feed made from a full-price mix or a single feed (pasture, meal, etc.), shaped by extrusion. It is usually cylindrical in shape and comes in various sizes depending on the type of animal to be...