- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home>Products>Kurkure Manufacturing Machine>Fully Automatic Kurkure Making Machine

Fully Automatic Kurkure Making Machine

As a Fully automatic kurkure making machine manufacturer, the kurkure machine is a special extrusion process design, the snacks extruder manufacturing process corn grits are moisturized by water in the flour mixer and fed to the Rotary Head Extruder. In the extruder, due to the rubbing of two rotary plates, the corn grits are squeezed and twisted to curls shapes. The cutting knives can cut them into required length. The Kurkure/Cheetos can be fried in fryer or toasted in oven and then cooled before flavoring.Due to their delicious tastes and nutrition, the kurkure very crunchy and delicious and easy for sale.

- Loyal

- KKM-1-F KKM-2-F KKM-3-F KKM-1-B KKM-2-B

- Shandong,China

- CE,ISO9001,SGS,BV

- 1 set/kurkure machine

- Contact Us

- Wooden case or wooden pellets depended on clients' requirement

- 30 working days

- T/T,L/C,D/P,Western Union,MoneyGram

- 30days /kurkure extruder machine

Fully Automatic Kurkure Making Machine Details

| Place of Origin | Shandong, China | Voltage | 220V/380V | Power(W) | 76KW |

| Weight | 1500KG | Dimension(L*W*H) | 17*2*2.5m | Certification | CE ISO |

| Warranty | 1 Year | Product name | Kurkure Snacks Making Extruder Machine | Material | SS304 |

| Type | kurkure chips making machine | Capacity | 150KG/H, 250KG/H, 500KG/H | Advantage | Low cost, high efficiency. |

| Energy | Electricity, oil diesel, gas, steam | Motor | SIEMENS, ABB and China brands | Craft | Twin-screw extruder |

| Need workers | 2-4 workers | Raw materails | Corn flour/ rice flour/ wheat flour and so on | After-sales Service Provided | Field installation, commissioning and training |

| Application | Snacks kurkure manufacturing plant |

Fully Automatic Kurkure Making Machine Description

Fully automatic kurkure making machine is one kind of extrusion process from food extruder manu.The kurkure corn meal is moisturized in the flour mixer with water and fed to the rotary die extruder. Under the extruding and kneading action of the two turntables made of brass from the extruder, through the screw fast running to get heat and pressure, make the corn meal gets heated and the moisture content gets reduced. The meal passed through the die and gets cut by the cutting knifes into irregular twisted strip-shaped materials, which are cut into products of the required length with a cutter according to customer requirements. Then it can goto fryer or roaster, and then sprayed flavor on the kurkure to improve their taste.Machines involved in making very crunchy and great kurkure.

Extruder of Fully Automatic Kurkure Making Machine

Kurkure machine produces snack food products -fried corn curl (sometimes referred to as Cheese curls,cheese puffs, Kurkure, Nik Naks, chataka pataka, Twisties or Bingo ).

Fully Automatic Kurkure Making Machine Samples Pricture

Benefits of rotary head extruder

|

The Advantagesof Snacks kurkure making machine process |

|

--Rugged construction designed can confrim kurkue extruder process continuous |

|

--Easy clean and maintain |

|

--speed control of feed screw |

|

--Motors are efficient heavy duty. |

|

--Manual head gap controlled by mechanical ratchet.Easy access to extruder component. |

|

--Screw and barrels and made of alloy steel die head bolts and nuts are of high tension |

kurkure manufacturing plant Design

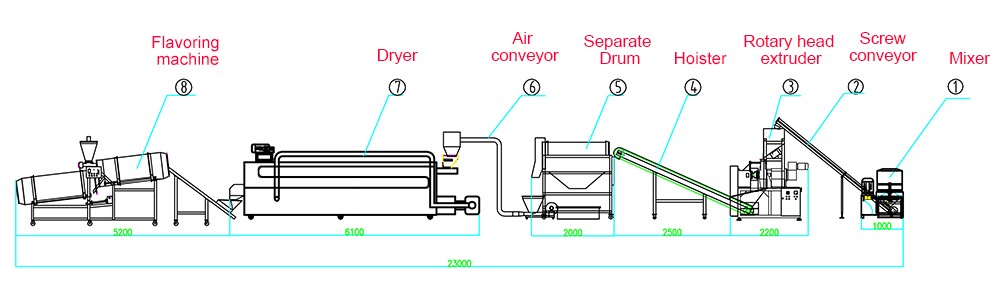

Flow Chart of Fully Automatic Kurkure Making Machine

|

kurkure products process flow chart on kurkure manufacturer |

|||

|

Fried kurkure extruder machine |

Baked kurkure extruder machine |

||

|

1 |

Flour Mixer |

1 |

Flour Mixer |

|

2 |

Screw Conveyor |

2 |

Screw Conveyor |

|

3 |

Rotary Head Extruder |

3 |

Rotary Head Extruder |

|

4 |

Hoister |

4 |

Hoister |

|

5 |

Separating Drum |

5 |

Separating Drum |

|

6 |

Hoister |

6 |

Vibrate Feeder |

|

7 |

Multi-layer Oven |

7 |

Continuous Fryer |

|

8 |

Flavoring Line |

8 |

Vibrate De-oil Machine |

|

|

|

9 |

Flavoring Line |

Fully Automatic Kurkure Making Machine Workshop Factory

Technical Parameters For KURKURE MANUFACTURING PROCESS

|

Technical Parameters of Kurkure Making Machine |

||||

|

Model |

Installed Power |

Power Consumption |

Output |

Size (L*W*H) |

|

Fried kurkure manufacturing machine |

||||

|

KMM-1-F |

134kw |

94kw |

125-140kg/h |

17000x1100x2500mm |

|

KMM-2-F |

136KW |

95kw |

200-230kg/h |

17300x1200x2600mm |

|

KMM-3-F |

196kw |

147kw |

400-460kg/h |

17300x2000x2600mm |

|

Baked kurkure manufacturing machine |

||||

|

KMM-1-B |

74kw |

52kw |

125-140kg/h |

16000x1100x2500mm |

|

KMM-2-B |

76kw |

53kw |

200-230kg/h |

16300x1200x2600mm |

KURKURE MAKING MACHINE PRICE

|

KKM-1-F kurkure extruder cost VS. KKM-2-F extruder cost |

Electrical Heating |

Gas Heating |

|||

|

Price |

capacity |

Price |

capacity |

||

|

Fried |

KKM-1-F |

$38000 |

125-140kg/h |

$58000 |

125-140kg/h |

|

KKM-2-F |

$38000 |

200-230kg/h |

$58000 |

200-230kg/h |

|

|

KKM-3-F |

$53000 |

400-460kg/h |

$73000 |

400-460kg/h |

|

|

Baked |

KKM-1-B |

$28000 |

125-140kg/h |

$32000 |

125-140kg/h |

|

KKM-2-B |

$32000 |

240-260kg/h |

$35000 |

240-260kg/h |

|

KURKURE MAKING MACHINE CUSTOMER CASE

|

2021 Kurkure Making Machine Customer Order Form |

|

Customer Have Formula Of Cheese Corn Curls Making Machines In 2021 |

|

100-150KG/H cheese corn curls making machines For Sale Botswana |

|

LY-5 cheese corn curls manufacturers for sale Pakistan |

|

500kg/h high quality cheese corn curls Machine products line Moldova |

|

100-150kg/h kurkure/Nik naks/cheetos making extruder machine for sale Ukraine |

|

200kg/h Oil Curtain Fried Cheetos/Nik Naks/Corn Curls/Kurkure machine for India |

|

1T/H Kurkure/Cheetos/Nik Naks/cheese curls snack For Sale Puerto Rico |

|

500KG/H Nik Naks Production Line For Sale Dominica |

|

Customer Have Technology Of Cheese Corn Curls Making Machines In 2021 |

|

1T/H korn curls making machine plant in Senegal |

|

150KG/H Small cheese corn curls Making Machines In Nigeria |

|

1T/H Nik Naks Manufacturing Plant For Sale Cote d'Ivoire |

|

LY-2 korn curls machines equipment For Sale South Africa |

|

Small electric kurkure chips cheetos making machine plant for sale Lebanon |

|

500-600kg/hcheese corn curls making machine plant making machine for sale UAE |

|

LY South African korn curls For Sale Tashkent |

|

1T/H Nik Naks Making Machinery manufacturer for sale Uzbekistan(Gizak) |

|

China LY-2 puffcorn curls machines equipment |

|

puffcorn curls manufacturer making machine DSP-120B for sale Russia |

|

1T/H Nik Naks Making Machinery manufacturer plant Thailand |

|

Customer Case Of The Kurkure Chips Cheetos Making Machine Plant In 2021 |

|

Uzbekistan 1T/H kurkure chips cheetos making machine plant Sale Uzbekistan (Tashkent) |

|

LY-3 Nik naks machines equipment for sale Uzbekistan |

|

LY-2 cheese corn curls machines equipment plant for sale Zimbabwe |

|

LY-1 kurkure chips cheetos making machine plant for sale Turkmenistan |

|

LY-2 South African Nik Naks for sale Honduras |

|

Simple Design LY-2 puffcorn curls machines equipment For Sale Bolivia |

|

150kg/h SmallNik Naks Making Machinery manufacturer Plant For Sale Tanzania |

Related Processing

| What is the Kurkure Production Line? |

| Do You Know This Type Of Kurkure Production Line? |

| How To Manufacture Kurkure From Rotary head extruder? |

Related Videos

| How to Fully Automatic Kurkure Making Machine? |

Product Categories

- Macaroni Production Machine

- Instant Noodle Machine

- Biscuit Making Machine

- Nutrition Bar Manufacturing Equipment

- Bread Crumb Machine

- Food Extruder Machine

- Corn Flakes Production Line

- Corn Puff Snacks Production Line

- Nutritional Baby Rice Powder Food Machine

- Dog Food Manufacturing Equipment

- Feed Production Line

- Cold Pressed Pet Food Machine

- Soya Nuggets Extruder

- Artificial Rice Production Line

- Doritos chips making machine

- Pellet Snack Making Machine

- Modified Starch Machine

- Kurkure Manufacturing Machine

- Industrial Microwave Oven

- Fried Dough Extruder Machine

- Industrial Deep Fat Fryer

- Wafer Line

- Automatic Packaging Machine

Contact Us

- Shandong Loyal Industrial Co.,Ltd.

- Telephone+86 13256674591

- Email[email protected]

- WhatsApp+86 13256674591

- WeChat13256674591

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -The Qihe Yellow River Material Warehouse, No. 689, Meili North Road, Jinan City, Shandong Prov

Sunshine Snacks Corn Curls Manufacture Process Line

Sunshine Snacks Corn Curls Manufacture Process Line Nik Naks Food Kurkure Making Machine

Nik Naks Food Kurkure Making Machine Fully Automatic Kurkure Production Line

Fully Automatic Kurkure Production Line kurkure Production Line Manufacturing Process

kurkure Production Line Manufacturing Process