- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Company News> Automatic Mini Small Hello Panda Biscuit Making Machine For Thailand Customer

Automatic Mini Small Hello Panda Biscuit Making Machine For Thailand Customer

2022-01-19 08:53:21Automatic Mini Small Hello Panda Biscuit Making Machine For Thailand Customer by Shandong Loyal Industrial Co.,Ltd. , we provide latest information about the products regularly.

6th, June, 2021 We signed a sales contract for a 500kg/h Automatic Mini Small Hello Panda Biscuit Making Machine with a Thai customer. This Thai customer contacted us by browsing our website, he is from Thailand and wanted to produce the popular Thai Ao Chi Durian Flavored Sandwich Cookies, which are round soft sweet cookies similar to the rich durian flavour. Ingredients include flour, sugar, vegetable oil and durian flavor. This Thai customer is a well-known local solution agency in Thailand, helping people with no import experience to provide solutions. The final customer currently has a 400kg/h biscuit production line, which is a well-known local biscuit manufacturer, producing all kinds of biscuits, cakes, etc. Shandong Loyal Industrial has nearly 10 years of experience in exporting food processing equipment to the Thai market. This time, it can be said that it is a powerful alliance to cooperate with Thai customers.

The solution company has rich service experience, with the quality assessment department, and there was a special food mechanical engineer to connect with me, who is really professional. Engineer is very concerned about the quality of equipment, motor brand, actual output and after-sales service.

|

Abb motor of biscuit manufacturing machine |

||

|

1 |

Package level 1 units: |

0 carton |

|

2 |

Product name: |

3-phase squirrel cage motor |

|

3 |

Product net weight: |

5.9 kg |

|

4 |

Product type: |

3aa2__m3aa_ie2_aa |

|

5 |

Scip: |

27ac6190-e1ce-4080-8654-6552aaabbe58 finland (fi) |

|

6 |

Selling unit of measure: |

Piece |

|

7 |

Standards: |

Iec 60034-1 |

|

8 |

Starting of motor: |

Direct online |

I showed him the parameter sheet of the biscuit making machine, show him the production process by video call, and also invite him to visit our factory.

This coincided with his idea. He found a special quality inspection agency to inspect the biscuit production line in our company. Checked out our company's quality management system, CE certificate, 9001 certificate, patent certificate and more. The quality inspection agency has a real-time video call with Thai customers, showing our factory, equipment, workers' processing process, etc.During the inspection process, Thai customers have always praised us, saying that our factory is big, bright and beautiful.This makes him more confident to cooperate with us

For the after-sale service, I put together a table, Customers think that our company system is very sound and very satisfied.

|

Service for hard biscuit making machine/soft biscuit making machine |

|

|

1.Installation |

we will send 1 engineers to the buyer’s factory for a 10-day period installation and training to the operators. |

|

2.allocation chart |

After the receipt the advanced payment , we will provide allocation chart at the buyer’s request. When effect the shipment, we’ll provide English Version of Installation / Operation / Service / Maintenance Manual. |

|

3.Easy damaged parts |

(gasket/plastic parts/rubber parts) free in one year |

|

4.After-sale Service |

available, Provide the basic formula |

|

5.Technical Support |

The customer can inform machine related problems to us via telephone, email or fax. All information will be recorded and will be reported to the After-sale Service team. Meanwhile, the sales person will be tracking the case until problem solved. |

|

6.Service Team |

We have a professional After-sale Service team including 10 professional engineers with at least 6 years working experience. They can handle technical consultation about manufacturing process, maintenance, fault diagnosis and troubleshooting, etc. |

For the formula and raw material of hard biscuit making machine, I shared some of my experiences with him:

For cookies or biscuits, it is better to use 60 mesh or 80 flour. Choose low-gluten flour or high-gluten flour according to the characteristics of the biscuits(soft biscuit&hard biscuit).

|

List Of Sandwiching Biscuit Raw Material |

|

|

Raw Material For Biscuit : |

Wheat Flour,Butter,Sugar,Powder,Milk Powder, Loosening Agent,Egg |

|

Filled Core Material: |

Cream ,Jam,Butter ,Chocolate Etc. |

|

Finished Biscuit Type: |

Soft Biscuit,Hard Biscuit ,Butter Cookies, Sandwich Cookies, Soda Cookies, Animal Cookies, Vegetable Cookies Etc |

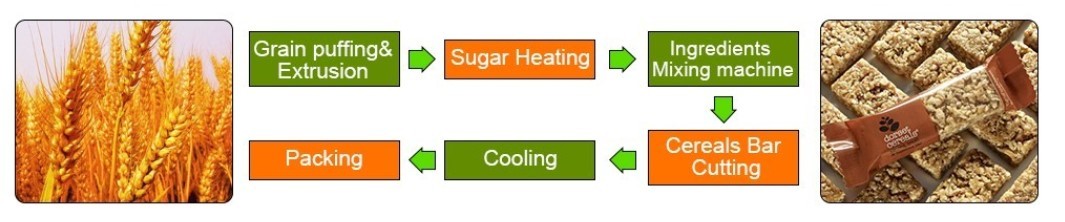

After understanding the biscuit recipe and precautions, I gave him a detailed introduction to the technological process and steps of the 500kg/h biscuit production line. Combined with the end customer's existing factory drawing, we provide the production flow chart and function introduction of the 500kg/h production line, so that he can more clearly understand the purpose and location of each machine.

After we gave the Thailand customer information about biscuit machine, the customer's most concerned issue is the payment method. We finally decided to pay 40% deposit by T/T first, and settle the balance before delivery after the machine is produced.

Now the customer has received the machine and sent me a video of the machine in action. All is well. Hope this production line can generate more profit for them.

Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines Automatic Cookies Making Machines

Automatic Cookies Making Machines Biscuit Sandwiching Machines

Biscuit Sandwiching Machines Automatic Biscuit Production Line

Automatic Biscuit Production Line Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line