- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Company News> Components of corn flakes production line

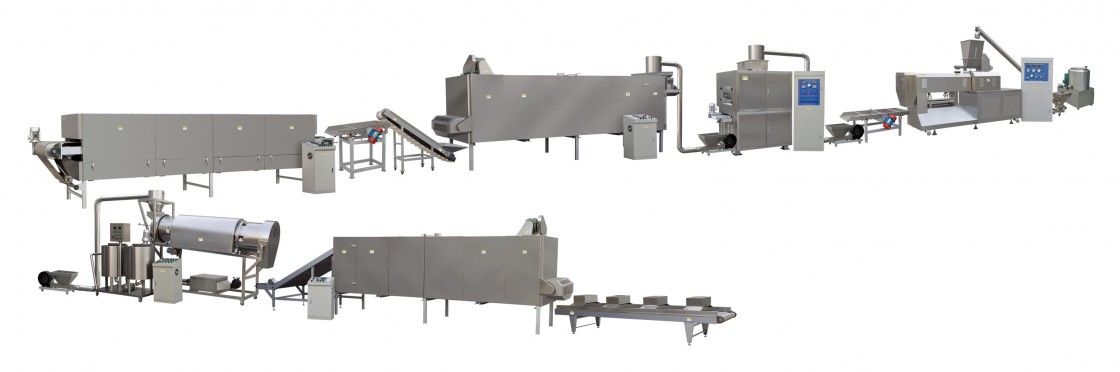

Components of corn flakes production line

2023-05-18 16:42:17Introduction:

Corn flakes are a new type of fast food, long lasting, portable and can be eaten directly or processed into other foods. When used, they are prepared in boiling water to make a tortilla chip punch. If you put the corn flakes into a prepared soup, you can make a corn flakes soup. Corn flakes have a high nutritional value and are rich in dietary fibre, which promotes bowel movement, accelerates faecal excretion and is rich in vitamins. Its main effects: weight loss, cancer prevention and anti-cancer, prevention of cardiovascular blood vessels, lowering blood pressure and blood lipids, and improving memory.

People who use their eyes a lot can eat more food made from corn, which can ease the loss of vision. People in general can eat corn products, but people with a weak stomach must be careful with them.

The Production Line Details :

|

Capacity |

150-200KG/h;180-220KG/h,300-500KG/h;800-1000KG/h |

|

Electricity supply |

Customized according to your local electricity situation. |

|

Machine details |

1. Stainless steel,:201, 304, 316, on request. 2. Electrical components can be ABB, Delta, Fuji, Siemens; famous brands. |

|

Certificates |

CE,GOST,TUV,BV |

|

Raw material |

Corn flour Sugar. Chemical additives |

|

Product colour |

Purple, Brown, Black, White, Golden yellow and other colors |

Flow Chart of Core Filling Snacks production line:

- Mixer--2.Screw Conveyor--3.Twin Screw Extruder--4.Vibrate cooling--5.Air Conveyor----6.Flaking Machine--7.Air Conveyor--8.Pre-dryer--9.Hoister--10.Vibrate Feeder--11.Baking Machine--12.Sugar Sprayer--13.Vibrate Feeder--14.Multi-layer Oven--15.Cooling Conveyor

Flow Chart Diagram:

Feature Of corn flakes production line:

1.High degree of automation: It has a very high degree of automation, which can well meet the needs of customers and fully meet the needs of various enterprises.

2.Large output: It can realize multiple batch processing, thus avoiding problems such as equipment downtime and long downtime due to different batches. The output of the equipment is large, thus ensuring the production efficiency and quality. At the same time, the production speed of the equipment is fast, and the output can be adjusted at any time according to the output needs of different users.

3.Low energy consumption: It can effectively reduce the utilization rate of energy and achieve the purpose of saving costs.

4.Sanitation and cleaning: The equipment adopts a new type of dust removal equipment, which can well avoid dust pollution to the surrounding environment and ensure environmental hygiene. In the process of processing, a certain amount of dust will be generated. If the dust is not effectively removed, the dust will cause harm to the health of the workers.

5.Easy to operate: The device is easy to operate and easy to use, whether it is a small-scale enterprise or a large-scale enterprise, it can be easily used.

The above are the characteristics of the bread crumb production line. This equipment has the advantages of large output, high efficiency and low energy consumption, and can meet the needs of various customers.

The Parameter Of Corn Flakes Process Line:

|

Model |

Power Consumption (kw) |

Output

(kg/h) |

Size (L*W*H) (mm) |

|

LY65 |

45kw |

150-200kg/h |

39000*1200*2200rnn |

|

LY70 |

30kw |

180-220kg/h |

41000*1500*2200nm |

|

LY85 |

55kw |

300-500kg/h |

43000* 3500*4300mm |

|

LY90 |

90kw |

800-1000kg/h |

65000* 5000*4300mm |

Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines