- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Processing> Corn Puff Snacks Making Machine Manufacturing Process

Corn Puff Snacks Making Machine Manufacturing Process

2020-07-09 10:44:32Find latest Corn Puff Snacks Making Machine Manufacturing Process, popular food processing machine events and top food processing equipment manufacturers in food manufacturing equipment, Industrial Microwave Oven,Industrial Dryer,Biscuit Making Machine.

Corn puff snacks making machine manufacturing process is mainly for core filling snacks and direct extruded snacks. puff extruder machine technology (also known as twin screw extruder technology) is to use advanced puff maker machine technology in the twin screw. The corn puffs processing line takes rice, corn or other grains as raw materials, uses pure cream as the medium, dilutes the raw materials such as egg yolk powder, milk powder, icing sugar, sesame paste, chocolate powder, etc., and mixes it into a core filling snacks. The material is injected into the puffed cereal food and processed into acore filling extruded snacks. latest snacks food processing machines can produce small products such as Maixiang chicken nuggets, sandwich rice crackers, puffed rice crackers, wheat rings, wheat roast, onion rings, and shrimp strips.

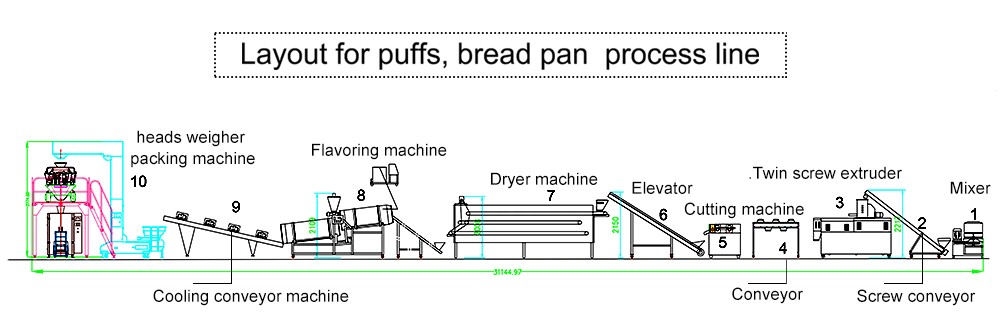

Corn puff snacks manufacturing plant:

Raw material mixing-conveying-twin screw extruder-core filling machine-shping cutter-Drying-seasoning-cooling packaging

|

Puff Snacks food manufacturing project report |

||

|

1 |

Flour Mixer |

The powdered raw materials are mixed according to the formula ratio, and the moisture of the mixed raw materials is kept at 12-14% (the water content of the twin screw extruder is adjusted to 18-20%). Rice and corn are 5: 1 The best mixing effect, the twin screw powder needs more than 60 mesh, choose the appropriate powder mixer according to the production line output and the viscosity of the raw material |

|

2 |

Screw Conveyor |

Using the motor as the power screw conveying, the mixed raw materials are conveyed to the feeding hopper of a certain height extruder to ensure that the feeding is convenient and fast |

|

3 |

Twin screw extruder |

It is main machine, the quality of the material expansion directly affects the final texture and mouthfeel, the material undergoes high temperature (about 130℃-170℃) during extrusion, high pressure (5-10 atmospheric pressure) becomes a fluid gel state, It is extruded uniformly and steadily through a specially designed die to complete the expansion. At the same time, the filling material is extruded through the core filling snacks machine, and it is evenly injected into the expanded roll through the core filling die. It is extruded together with the expanded material, and the moisture of the material drops to 9 during extrusion —10%. According to the different output of the puff snacks production line, different types of 65\70\75\85\95 puffing hosts are selected, and the output can vary from 100kg/h to 1000kg/h. According to the products made, different types of puff maker machine can be selected. |

|

4 |

Shape cutting machine |

After the core filling puffed material is extruded from the die hole, its shape is not the final product. It needs to be cutting to the shaping machine. After being shaped by two forming rollers, it is cut by a cutter into a roll of a certain length and a uniform thickness. , Cakes and other foods, the material is cooled at this time, and the water content is reduced to 6-8%. |

|

5 |

Core filling machine |

Fill the core filing puff snacks with chocolate, cream, egg yolk, peanut butter, jam, etc. Preparation of stuffing: Since cream has good stability and lubricity, and can give better flavor to the product, it is more ideal to use cream as the carrier for the core filling snacks. The pure cream is heated and melted, then cooled to about 40°C, and various fillings are added in proportion (the various raw materials should be powdered to more than 60 mesh) and stirred evenly. In order to ensure the quality of the product, the cream should be added in an appropriate amount to ensure that the material is diluted It is uniform and has good fluidity. (Cream should be pure cream, not mixed with water). |

|

6 |

Hoister |

The automatic transportation of various equipment products, according to the needs of different products, there are choices of PVC conveyor belts and stainless steel conveyor belts, customized processing according to output and plant restrictions |

|

7 |

Continuous dryer machine |

Puffed food makes the product more crispy and tastes better by roasting, increasing the taste, while drying the material moisture, increasing the shelf life. After baking, the moisture of the raw material drops to 2-3%. According to the configuration requirements of the puffs snacks production line, the oven can be divided into climbing oven and ordinary oven. According to the energy method, electric heating, natural gas heating and steam heating can be selected. According to the drying temperature, a high-temperature drying box and a low-temperature drying box can be used, and a circulation structure and a constant flow structure can be selected according to the internal structure. The temperature is adjusted by the control cabinet between 0-200 degrees. The part that contacts the puffed food is stainless steel structure. The baking time can be adjusted according to the speed |

|

8 |

Coating system |

Mixing is carried out in the drum, including oil spraying and seasoning on the surface of the blank, oil spraying is to prevent the product from absorbing moisture, giving the product a certain stability, extending the shelf life, spraying seasoning is to improve the taste and flavor, With the rotation of the drum, the material enters from one end and comes out from the other end. The oil spray is performed when the material enters the drum. By tumbling and stirring, the oil is evenly coated on the surface of the material. When the material passes through the middle of the drum, seasoning is added to continue mixing (roll only No stirring) The product coming out of the drum is the finished product. The product should have the same color and luster. The surface is a pleasing golden yellow, and the sealing is beautiful and smooth. There are octagonal barrel, single drum, double drum seasoning line, according to the output, product nature configuration, and oil spraying, sugar spraying, coating equipment. In order to meet the needs of market development, batch weighing and blending equipment, single-head octagonal seasoning machine, double-head octagonal seasoning agent, positive and negative reversal seasoning machine were developed. Improve the product mixing uniformity and the precise control of the amount of seasoning added. |

Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines