- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Company News> Frozen French Fries Production Line

Frozen French Fries Production Line

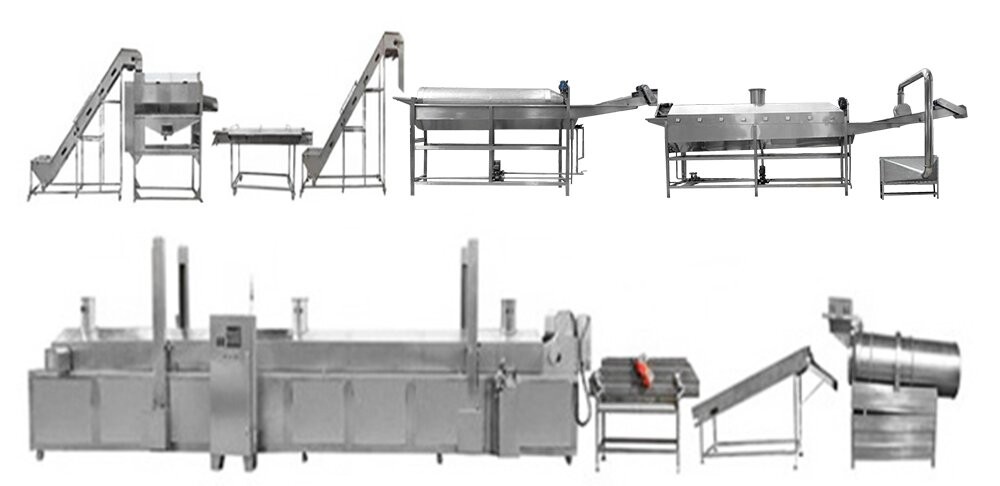

2023-06-17 16:06:21A Frozen French Fries Production Line is a series of machines and equipment used for the mass production of frozen French fries. It typically includes processes such as potato washing, sorting, peeling, slicing, blanching, drying, frying, cooling, freezing, and packaging. The production line is designed to automate and streamline the production process, ensuring consistent quality and efficiency in producing large quantities of frozen French fries.

The Flowchart Of Frozen French Fries Production Line

- Potato Receiving --- 2. Washing And Peeling --- 3. Sorting--- 4. Slicing --- 5. Blanching --- 6. Frying-Cooling --- 7. Freezing --- 8. Packaging --- 9. Storage And Distribution

The Function Of Frozen French Fries Production Line

The frozen French fries production line is designed to efficiently process raw potatoes into frozen French fries that are easy to make and eat.

The main functions of the production line are as follows:

- Raw Material Handling: This involves receiving and checking the quality of raw potatoes before they are used in the production process.

- Washing And Peeling: Raw potatoes go through a washing and peeling process to remove any dirt or debris from the skin. This ensures clean, high-quality potatoes for further processing.

- Dice Or Slice: Slice or cut the peeled potato to the size and shape desired for French fries. This can be done by using specialized machines.

- Blanch: Blanch the cut potatoes with hot water or steam to remove excess starch. This process also helps to partially cook the potatoes, ensuring a consistent texture and color.

- Drying: The blanched potatoes are dried to remove surface moisture. This step is critical to getting crispy chips during frying.

- Frying: Put the sun-dried potato chips into vegetable oil and fry them at a specific temperature and time to achieve the ideal golden color and crispy taste. This step gives French fries their characteristic flavor and appearance.

- Quick-Freezing: The fried French fries are quickly frozen by quick-freezing technology. This ensures that the fries are individually frozen and do not stick together, maintaining their quality and preventing ice crystals from forming.

- Packaging: Pack frozen French fries into bags or cartons. Packaging may include the addition of preservatives or other additives to extend shelf life and maintain quality during storage.

- Storage And Distribution: Packaged frozen french fries are stored in special freezers to keep them frozen. They are then distributed to retailers, supermarkets or restaurants for sale and further distribution.

Throughout the production line, quality control measures are implemented to ensure that French fries meet the required standards for taste, texture, appearance and safety. This includes monitoring and adjusting processes, ingredient quality checks, and compliance with food safety regulations.

The Parameter Of Frozen French Fries Process Line

|

Parameter Of Fully Automatic Frozen French Fries Process Line |

||||

|

Output (kg/h) |

Power (kw) |

Water Consumption (t/h) |

Steam Consumption (kg/h) |

Workshop Area (m²) |

|

100kg/h |

50kw |

4 t/h |

300kg/h |

300m² |

|

200kg/h |

55kw |

5 t/h |

400kg/h |

400m² |

|

300kg/h |

60kw |

6 t/h |

500kg/h |

500m² |

|

500kg/h |

125kw |

7 t/h |

600kg/h |

600m² |

Advantages of Frozen French Fries Process Line

|

Efficiency |

Frozen French fries lines are designed to handle large quantities of raw potatoes and produce large quantities of frozen French fries. This allows mass production and reduces overall processing time. |

|

Consistency |

This line ensures consistent quality of frozen French fries in terms of size, shape, texture and taste. This is achieved by automating and standardizing processes, minimizing variation in the final product. |

|

Food Safety |

The production line follows strict food safety standards and regulations. It includes measures such as washing, peeling, blanching and frying at specific temperatures and times to eliminate harmful bacteria, reduce contamination and ensure product safety. |

|

Longer Shelf Life |

Frozen French fries have a longer shelf life than fresh cut French fries. The flash freezing process in the production line helps to maintain the quality and nutritional value of the fries, while also preventing the growth of bacteria and other microorganisms. |

|

Convenience |

Frozen French fries can be stored for a long time without deterioration, and it is easy and convenient to make. They are ready for consumers to cook at their convenience, providing a quick, hassle-free meal option. |

|

Cost-Effective |

This production line simplifies the process from raw potatoes to frozen French fries, reduces labor costs and improves overall efficiency. The ability to produce large batches also enables economies of scale, making the production process more cost-effective. |

|

Versatility |

Frozen chips are versatile and suitable for both home and commercial cooking. They can be baked, fried, or air-fried, and can be flavored or flavored to your liking. |

|

Consistent Availability |

Frozen french fries can be produced year-round regardless of the seasonal availability of potatoes. This ensures a continuous supply of French fries for consumers, restaurants and foodservice establishments. |

|

Reduce Waste |

The production line effectively utilizes raw potatoes by reducing waste. Any by-products or scraps can be used for other purposes, such as animal feed or further processed into other potato products, thereby minimizing the impact on the environment. |

What’s Advantage Of Frozen French Fries?

|

Convenience |

One of the main advantages of frozen french fries is convenience. They come pre-cut, pre-cooked and frozen, making them quick and easy to prepare. With frozen french fries, you can have a delicious side dish or snack without a lot of prep work or cooking skills. |

|

Time Saving |

Frozen French fries can save your time in the kitchen. Unlike making fresh french fries from scratch, which involves washing, peeling, cutting and frying, frozen french fries simply require heating them. This is especially beneficial when you are pressed for time or want a quick meal or snack. |

|

Consistent Quality |

Frozen French Fries are manufactured and processed using standardized methods to ensure consistent quality and taste. This means you can expect the same level of crunch, texture and flavor every time you cook them. |

|

Extended Shelf Life |

Frozen French fries have a longer shelf life than fresh potatoes. They can be stored in the refrigerator for months without spoiling, making it easy for meal planning and reducing food waste. |

|

Versatility |

Frozen French fries can be cooked in different ways according to your preference. You can bake them in the oven, deep fry them for a crunchy texture, or even air fry them for a healthier option. Plus, you can flavor or add toppings to your frozen fries to enhance their taste and customize them to your liking. |

|

Year-Round Availability |

Frozen French fries are available year-round, regardless of potato seasonality. This ensures that you can enjoy French fries anytime, no matter what time of year or whether fresh potatoes are available. |

|

Cost-Effective |

Frozen fries are often a better deal than buying fresh potatoes and making your own. They are often sold in bulk or in large quantities, giving you great value for your money. This makes them an affordable option for individuals and families on a budget. |

|

Minimal Prep And Cleanup |

Since frozen french fries are pre-cut and pre-cooked, there is minimal prep work. This saves you time and energy in the kitchen. Plus, compared to making fresh fries, there is no cleanup required as there are no peels or dirty pots or pans to deal with. |

|

Kid-Friendly |

Frozen french fries are often a hit with kids. Their crunchy texture and familiar taste appeal to young palates, making them a convenient and enjoyable choice for families. They can be easily incorporated into kids' meals, party snacks, or even as a side dish for picky eaters. |

In summary, the advantages of frozen chips include convenience, time savings, extended shelf life, consistent quality, versatility, year-round availability, cost-effectiveness, minimal preparation and cleanup, and their appeal to young children. These factors make frozen french fries a popular choice for individuals, families, and food service establishments.

Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines