- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Processing> How About Extruded Fish Feed Processing Equipment Production Line

How About Extruded Fish Feed Processing Equipment Production Line

2021-01-23 15:36:08The extruded fish feed processing equipment production line can produce and process catfish, grass carp, crucian carp, tilapia, ornamental fish, soft-shelled turtle, bullfrog and other aquatic feed pellets.

Extruded fish feed processing equipment production line

Configuration: floating fish feed processing machine, floating fish feed extruder

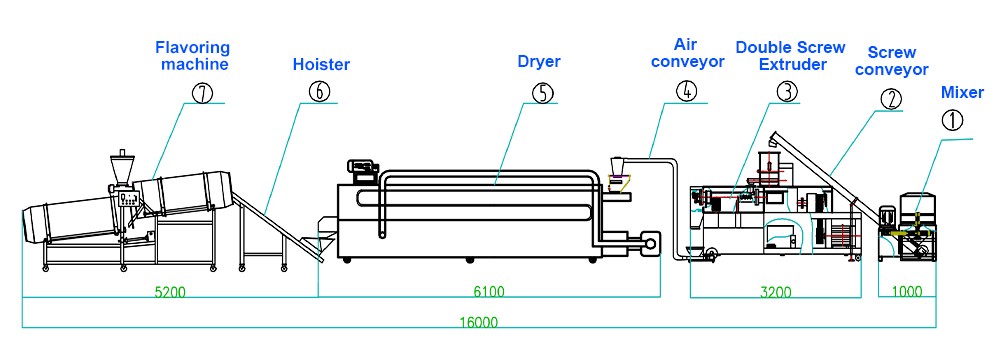

Chart of the production line of extruded fish feed processing equipment:

Crusher → Mixer → Feeder → Twin-screw feed extruder → Conveyor → Multi-layer drying equipment → Seasoning line → Cooling conveying → Vibrating screen → Packaging machine

Fish feed size range: 1mm, 1.5mm, 2.0mm-10mm.

The extruded fish feed processing equipment production line can produce and process catfish, grass carp, crucian carp, tilapia, ornamental fish, soft-shelled turtle, bullfrog and other aquatic feed pellets.

Due to the inherent characteristics of the extruder, the extruded feed product can have a certain degree of puffing effect by adjusting the process parameters of the extruder. Compared with ordinary feed pellets, the extruded feed product has the following three advantages:

1. Puffing makes the feed product more crispy, which is convenient for poultry and livestock to chew and eat

2. The maturation effect of the extruded product can reach 100%, which is equivalent to feeding cooked food to animals, and the nutrition is easy to absorb

3. After expansion, the original specific gravity of the material is changed, which means that the fish feed produced by this set of feed equipment can be selectively floated, suspended, and sinked to the bottom after being fed into the water, so as to adapt to different water layers of fish. food

The superior performance of the extruded fish feed processing equipment production line:

1. The main motor, feeding motor and rotary cutting motor of this machine adopt frequency conversion control, which is energy-saving and easy to operate.

2. The main gear box is equipped with gear oil pump cooling, lubrication system, twin-screw extrusion pumping mechanism to make the material mature enough, and the gelatinization degree of the material reaches more than 98%.

3. Wide variety of raw materials, meat content is as high as 40%. Changing the mold can produce fish food, cat food and other products.

4. The screw has a self-cleaning ability, and there is no need to clean the boring and screw when restarting or changing material varieties.

5. The screw and screw sleeve are made of special materials, special process, wear resistance and high pressure.

6. Each temperature zone has a temperature control table to control the temperature.

7. The feed is sterilized by high temperature and high pressure during processing, which ensures the sanitation and safety of feed products.

8. The cylindrical aperture of the discharge die d=1mm-10mm, and other special-shaped die holes (can be made according to customer requirements).

9. It is suitable for processing aquaculture extruded materials (floating-sinking, sinking), and the water stability is more than 24 hours.

10. It is also suitable for processing ornamental fish feed, raw materials, suckling pig feed, young animals, livestock and poultry puffed materials and high-quality puffed food.

The main part of the twin screw extrusion system is the screw and screw sleeve. The two screws are left-handed, meshed with each other and rotate in the same direction. In the working process, the materials sticking to the screw are scraped and pushed forward. The screw is composed of seven parts, and the materials are being pushed. Increase the mixing and extrusion ability of the material, increase the contact area of the material to the sleeve, facilitate the absorption of external heating, and facilitate the maturation of the material. The screw is connected by a spline shaft sleeve to form a whole concentric screw. This connection method is interchangeable, convenient for assembly and disassembly, and easy to replace. The rotary cutting device is composed of a motor, a knife holder, and a belt pulley. The knife holder is fixed on the die body. The motor drives the knife holder to rotate through a belt to cut the material. The matching molds of this machine include round hole shape, plum blossom shape, column shape, sheet shape, etc.

This system is composed of a gear pump, an oil tank and an oil circuit, for forced lubrication and cooling of the rotating parts of the distribution box. The speed control system of this machine adopts frequency conversion speed control technology, which has reliable adjustment, large adjustment range and stable operation.

Floating Fish Feed Extruder Machine

Floating Fish Feed Extruder Machine Fish Feed Making Machine

Fish Feed Making Machine  Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines