- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Company News> How Do You Make Corn Filling/Inflating Snacks?

How Do You Make Corn Filling/Inflating Snacks?

2023-02-21 10:41:50Introduction Of Corn Filling/Inflating Snacks Production Line:

Corn Filling/Inflating Snacks Production Line is a typical type extruded food machine studied and developed by ourselves on the basis of learning from advanced technology in the world so that both its technical performance and products quality reach to the most advanced level in the world. Corn Filling/Inflating Snacks Production Line can finish mixing, extruding, shaping, core-filling, cuting, baking and flavoring in one-pass operation automatically. Corn Filling/Inflating Snacks Production Line features lots of types, flexible collocation, extensive applied raw materials, various snacks and easy operation. By changing the moulds and process technology, Corn Filling/Inflating Snacks Production Line can produce core-filled snacks, like chocolate filled bar, cream filled pillow, rice cake, cereal bar, sheet snacks etc.

The Details Of Automatic Corn Filling/Inflating Snacks Processing Line :

The Details Of Automatic Corn Filling/Inflating Snacks Processing Line :

|

Capacity |

120kg-1000kg |

|

Power Supply |

Based on 380V 50 Hz 3 phase. Customized according to your local power. |

|

Machine details |

1.Stainless steel,:201, 304, 316, on request |

|

Certificate |

CE,GOST,TUV,BV |

|

Raw Material |

Corn, rice, flour, sugar, etc. |

|

Products Color |

White, Yellow |

|

Products type |

Chocolate filled bar, cream filled pillow, rice cake, cereal bar, sheet snacks etc.. |

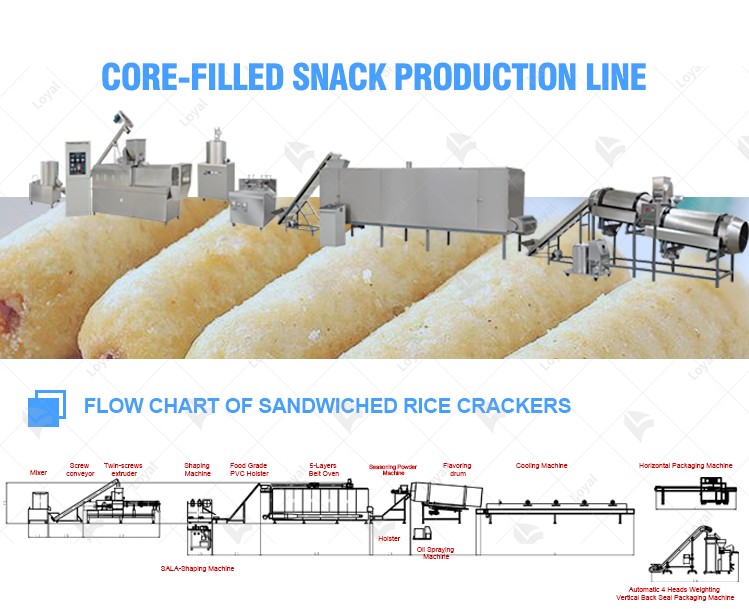

The Flow Chart Of Automatic Corn Filling/Inflating Snacks Production Line :

Mixing → Extrusion → Drying → Baking → Seasoning → Cooling → Packaging

The Equipment Using In The Core Filling/Inflating Snacks Making Machine:

The Equipment Using In The Core Filling/Inflating Snacks Making Machine:

1.Mixer --- 2.Screw Conveyer --- 3.Twin Screw Extruder --- 4.Core Filler --- 5.Multi-function Shaper --- 6.Hoister--- 7.Multi-layer Oven ---8. Flavoring Line ---9. Packing Machine

What Is The Advantages Of Corn Filling/Inflating Snacks Processing Line?

|

Mixer |

Rotate the stirring shaft at high speed through the motor, so that the raw materials in the barrel are fully mixed and evenly. |

|

Twin Screw Extruder |

Twin Screw is two screw, mostly named after the screw diameter. Screw Extruder has advanced die and cutting system, and give processors an entirely new set of templates to create its innovative shapes. Automatic lubrication system can lower down power consumption and prolong the life. |

|

Core Filler |

The sandwich material is stirred in the tube, and then the sandwich material is injected into the Screw Extruder. |

|

Multi-layer Oven |

The oven is a multi -layer circulating drying box, which has good thermal insulation and efficient energy saving. Multi -layer tape dryers are composed of major components such as mesh belts, feeders, drying bodys, mesh bands, heating devices, circulating fans, and damp fans. |

|

Hoister |

Used to transport the Corn Filling/Inflating Snacks from the oven into the next device. Usually a food -grade PVC upgrade. |

|

Flavoring Line |

The product comes out of the oven to the Hoister, enter the drum, spray the oil to the product, and roll and stir in the drum to ensure that the surface of the product has oil. |

|

Packaging machine |

Pack Corn Filling/Inflating Snacks and beautify the product etc. |

The Feature Of Core Filling/Inflating Snacks Machines:

①Versatility: The machine is capable of producing a wide variety of snack products, including core-filled and inflated snacks, with different shapes, sizes, and flavors.

②Efficiency: The machine is highly automated, which makes it faster and more efficient in producing snacks than manual processes. This helps to increase productivity and reduce labor costs.

③Precision: The machine is designed to produce snacks with a high degree of accuracy, consistency, and quality. This ensures that the snacks are uniform in shape, size, and filling quantity.

④Flexibility: The machine can be easily adjusted to accommodate different snack products, flavors, and production volumes.

⑤Hygiene and Safety: The machine is made of food-grade materials and is easy to clean and sanitize, which ensures that the snacks produced are safe for consumption.

What Is The Line Parameter Of Automatic Corn Filling/Inflating Snacks Production Line ?

|

Model |

Installed capacity |

Power Consumption |

capacity(kg/h) |

Dimension(m) |

|

LY65 processing line |

80kw |

55kw |

120-150kg/h |

21000*1200*2200mm |

|

LY70 processing line |

115kw |

95kw |

200-250kg/h |

23000*1500*2200mm |

|

LY85 processing line |

170kw |

140kw |

500-700kg/h |

28000*3500*2200mm |

|

LY90 sprocessing line |

230kw |

164kw |

800-1000kg/h |

29000*2500*3500mm |

The Applications Of Corn Filling/Inflating Snacks Production Line :

Corn Filling/Inflating Snacks Production Line can finish mixing, extruding, shaping, core-filling, cuting, baking and flavoring in one-pass operation automatically. Corn Filling/Inflating Snacks Production Line features lots of types, flexible collocation, extensive applied raw materials, various snacks and easy operation. By changing the moulds and process technology, Corn Filling/Inflating Snacks Production Line can produce core-filled snacks, like chocolate filled bar, cream filled pillow, rice cake, cereal bar, sheet snacks etc.

Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines