- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Processing> How Is Pet Chew Produced By Using The Automatic Pet Chewing Making Machine?

How Is Pet Chew Produced By Using The Automatic Pet Chewing Making Machine?

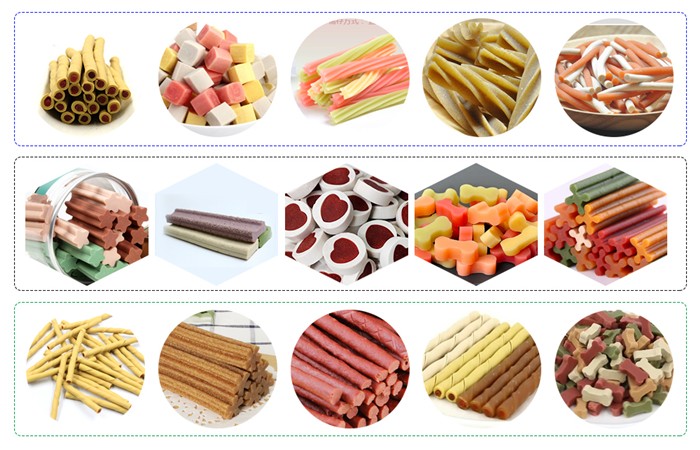

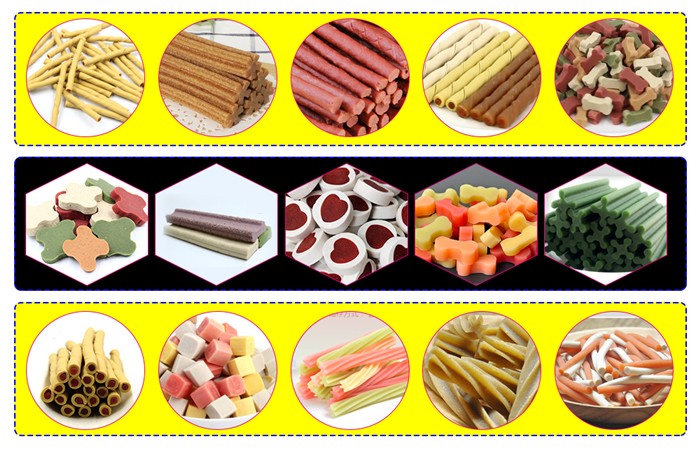

2020-12-09 15:13:32At present, the popular types of pet snack foods on the market are mainly chewing sticks, teeth sticks, tooth cleaning sticks, etc. There are two main functions: one is teeth grinding, leisure, passing time and entertaining; the other is to supplement the nutritional elements lacking in pets such as trace elements and minerals, so the chewing gum is sometimes called an energy bar.

At present, the popular types of pet snack foods on the market are mainly chewing sticks, teeth sticks, tooth cleaning sticks, etc. There are two main functions: one is teeth grinding, leisure, passing time and entertaining; the other is to supplement the nutritional elements lacking in pets such as trace elements and minerals, so the chewing gum is sometimes called an energy bar.

Pets often consume high-quality chews, which are beneficial to their health. According to this market demand, the pet chew production line developed by our company is specially used to produce high-quality chew products, which are extruded by a screw extruder into rod-like, bone-like and other different shapes of chew-type pet food. It can not only provide some essential nutrients for canine animals, such as protein, fat, vitamins, etc., but also grind teeth for dogs to satisfy the chewing habits of dogs. At the same time, it can also strengthen the gums and frontal bones, clean the mouth, and remove tartar, reduce disease transmission.

Introduction to the automatic dog chew production line:

The animal chew processing equipment production line uses powdered starch, glue and other low-expansion food-grade raw materials as the main material, supplemented by meat, protein, vitamins, fiber and other nutrient. A complete set of automatic pet dog chewing production line that uses a single screw extruder to produce pet chew particles of different shapes through strong extrusion and instantaneous kneading.

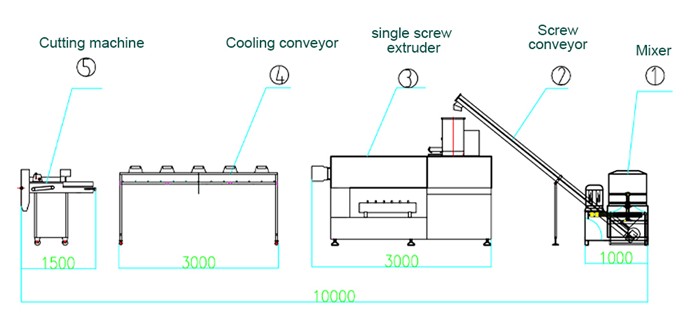

1. Process flow of industrial dog chewing equipment pet chewing equipment:

Raw material preparation → mixing → extrusion molding → cooling and conveying → cutting machine → conveying → drying → packaging

2. Automatic dog chewing equipment, pet chewing equipment configuration:

Powder mixer → extruder → puffing machine → cooling conveyor → cutting machine → hoist → drying oven → packaging machine

3. Commercial pet dog chewing equipment process line composition:

1. Flour mixing machine: Add a certain proportion of water to the raw materials (starch, corn flour, colloid, glycerin and vegetable oil, etc.) and mix well.

2. Feeding machine: the motor is used for screw conveying, and the mixed raw materials are conveyed to the feeding hopper of the extruder to ensure convenient and fast feeding.

3. Single screw extruder: In the high temperature and high pressure environment and screw extrusion, the die can be changed by adjusting the different feeds of the production department by adjusting the process. The specific particle size and shape can be changed. Because the production process of dog chew and dog food is different, single-screw extrusion requires precise temperature control, and all screw barrels adopt water temperature control system.

4. Cooling and conveying: After the mold comes out, the surface of the product is damp, and it is cooled and conveyed by traction to facilitate later cutting.

5. Cutting machine: Cut the chew into different sizes according to requirements, and control the length of the product by adjusting the distance of the eccentric wheel, which is simple to operate and easy to learn and understand.

4. Conveyor: Convey the chew to the oven, artificially dry the product, which is convenient for storage. It can also be dried naturally, but the cycle is long, the drying effect is not good, and it is not easy to store for a long time.

5. Multi-layer oven: the oven is mostly electric oven, the temperature is adjusted between 0-200 degrees through the control cabinet, the inside is stainless steel double-layer mesh bag, which reduces the moisture of feed particles, promotes the maturation rate and increases the shelf life.

4. Full automatic pet chewing production line advantages:

In terms of technology, the pet food production line uses powdered starch, glues and other low-expansion food-grade raw materials as the main materials. After extrusion and curing, the overall adhesion, high density, and high nutrient content are provided. Pets have good taste and interest, which strengthens and makes up for pets' needs for cleaning teeth, calcium supplements and happy mood in different periods. Therefore, the pet chew processed by this chew production line has better taste, high nutrition, chewy, bite, digestible, and less parasites than the traditional non-intensive production of extruded pet chews (such as handmade pig skin meat sticks). The advantage of high interest.

In terms of the process, this pet food production line of the complete set of equipment for processing animal chews and molar rods has no serious pollution such as noise and dust.

In terms of operation, this automatic dog chewing food production line of the complete set of equipment for processing animal chews and molar rods has a small footprint and is easy to operate. It does not require extra labor to minimize the labor cost of users.

Pet Food Production Line

Pet Food Production Line Dog Treat Biscuit Making Machine

Dog Treat Biscuit Making Machine Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines