- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Company News> Industrial Microwave Pumpkin Seeds Drying Technology

Industrial Microwave Pumpkin Seeds Drying Technology

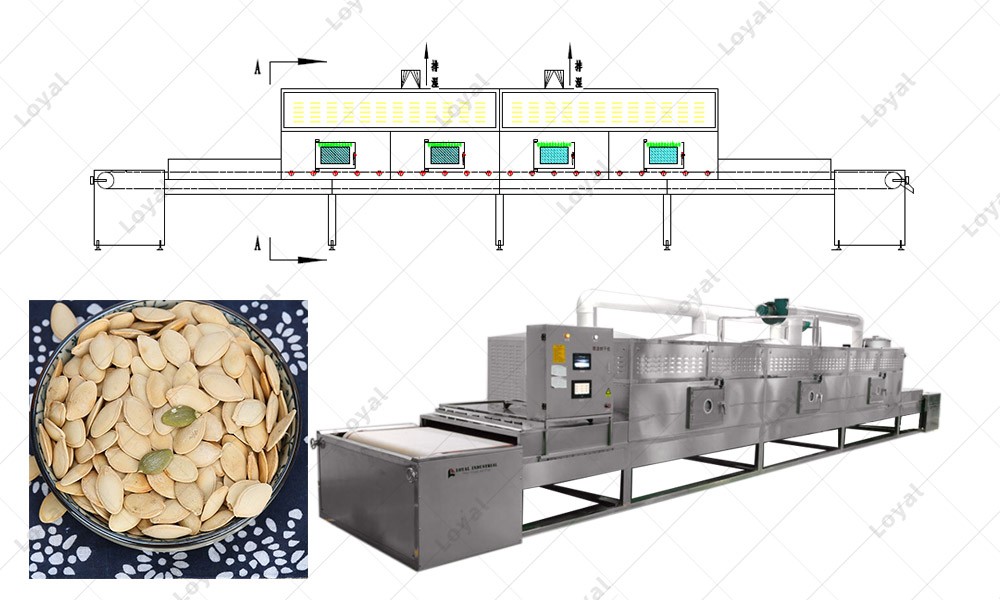

2023-03-29 11:08:00Introduction Of Microwave Pumpkin Seeds Drying Machine:

Microwave pumpkin seeds drying machine is a specialized equipment designed for drying pumpkin seeds using microwave technology. This machine is primarily used in food processing industries, where the drying of pumpkin seeds is an essential step in the production of various food products.The machine works by using microwaves to heat the pumpkin seeds, which removes the moisture content from the seeds. The microwave energy penetrates the pumpkin seeds and heats them from the inside out, resulting in a faster and more efficient drying process compared to traditional drying methods.

Microwave pumpkin seeds drying machines are designed to be efficient and cost-effective, as they consume less energy and have a shorter processing time than other drying methods. They also allow for greater control over the drying process, resulting in consistent and high-quality dried pumpkin seeds.

Parameter Of Microwave Pumpkin Seeds Drying Machine:

|

Equipment Model |

LY-100 Industrial Microwave Drying Machine For Pumpkin Seeds |

|

Rated Input Apparent Power |

Customization |

|

Height Of Conveyor |

600-1000mm |

|

Inlet And Outlet Height |

40-100mm |

|

Width Of Conveyor Belt |

750±100mm(Custom-Made) |

|

Microwave Leakage Standard |

ISO≤5mw/Cm² |

|

Operating Frequency |

2450±50Hmz |

|

Transmission Speed |

0~10m/Min(Adjustable Frequency) |

Feature Of Microwave Pumpkin Seeds Drying Machine:

|

1 |

Microwave technology |

The machine uses microwave technology to dry pumpkin seeds, which is a fast and efficient method compared to traditional drying methods. |

|

2 |

Uniform drying |

The machine's design ensures that the pumpkin seeds are evenly heated, resulting in uniform drying and consistent product quality. |

|

3 |

Precise control |

The machine allows for precise control over the drying process, including temperature and drying time, which helps to ensure that the final product meets the desired specifications. |

|

4 |

Energy-efficient |

The machine consumes less energy than traditional drying methods, which helps to reduce operating costs and improve efficiency. |

|

5 |

Automated operation |

The machine is designed for automated operation, with features such as a programmable control system and automatic temperature monitoring and adjustment. |

|

6 |

Compact design |

The machine has a compact design, which makes it easy to install and operate in small spaces. |

|

7 |

Stainless steel construction |

The machine is typically constructed of high-quality stainless steel, which is durable, easy to clean, and resistant to corrosion. |

Details Display Of Microwave Pumpkin Seeds Drying Machine;

Applications Of Microwave Pumpkin Seeds Drying Machine:

1.Snack food production: Dried pumpkin seeds are a popular snack food, and the microwave pumpkin seeds drying machine is used to produce high-quality dried seeds for this market.

2.Confectionery production: Dried pumpkin seeds are often used in the production of confectionery products, such as chocolate bars or coated nuts.

3.Ingredient production: Dried pumpkin seeds are also used as an ingredient in various food products, such as baked goods, granola bars, and trail mix.

4.Food preservation: Drying pumpkin seeds with the microwave pumpkin seeds drying machine is a common method of preserving them for later use, as it removes moisture and prevents the growth of bacteria and mold.

Advantages Of Loyal Microwave Drying And Sterilization Equipment:

1.Adopt Food Grade Stainless Steel, Nice Appearance, Easy To Clean.

2.Microwave Can Penetrate Through The Materials So That The Inside And Outside Are Heated At The Same Time, Short Processing Time,Evenly Drying And Thorough Terilization. No Extra Heat Loss, High Heat Efficiency, Saving Energy.

3.Thermal Effect And Non-Thermal Effect Work Together, Achieving Ideal Sterilization Effect At Low Temperature And Short Time, The Vegetable Can Keep Their Nutrition Components To The Maximum.

4.Adopt Non-Contact Infrared Temperature Measurement Technology, High Precision, Automatic Control.

5.Frequency Adjustable Conveyor Speed, Step-less Adjustable Microwave Power, Instant Heating And Stop, No Thermal Inertia,Convenient Operation.

6.Adopt Human-Machine Interface Operation And PLC Touch Screen Control, Realizing Automatic Control.

7.Microwave Leakages ≤1mw/ Cm2, No Heat Radiation, Improving The Work Environment.

Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines