- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Company News> Future Trends: Advancements in Microwave Spices Sterilizer Machine Technology

Future Trends: Advancements in Microwave Spices Sterilizer Machine Technology

2024-01-12 10:19:07Future Trends: Advancements in Microwave Spices Sterilizer Machine Technology.At {Shandong Loyal Industrial Co.,Ltd}, we prioritize client success through state-of-the-art solutions that enhance productivity and reliability. Our comprehensive range of fully automated microwave machinery is engineered to meet the evolving needs of diverse industries. We leverage the power of automation to optimize processes, ensuring a seamless and efficient operation that drives excellence in production.

Introduction

Shandong Loyal Industrial Co.,Ltd. a company specializing in manufacturing food processing equipment, headquartered in Shandong Province, China.The company adheres to the concept of "quality first, innovation leads" and is committed to providing high-quality, high-efficiency advanced equipment for the global food industry.We have established long-term cooperative relationships with many well-known food processing companies around the world, providing them with customized solutions. for example:DanTech UK Ltd,Thermex-Thermatron Systems .

In the realm of food processing, spice sterilization stands as a pivotal step, ensuring the safety and quality of the final product. Traditional methods, while effective, present challenges that impede efficiency and precision. This article delves into the promising future trends and advancements in Microwave Spices Sterilizer Machine technology, aiming to revolutionize spice processing.

Current Landscape of Spice Sterilization

The existing landscape of spice sterilization is predominantly characterized by traditional methods, including heat treatment, steam, and chemical processes. While these methods have been effective over the years, they often come with drawbacks such as extended processing times, inconsistent results, and potential alterations to the flavor and quality of spices. This section will delve deeper into the challenges posed by current practices, highlighting the need for technological advancements.

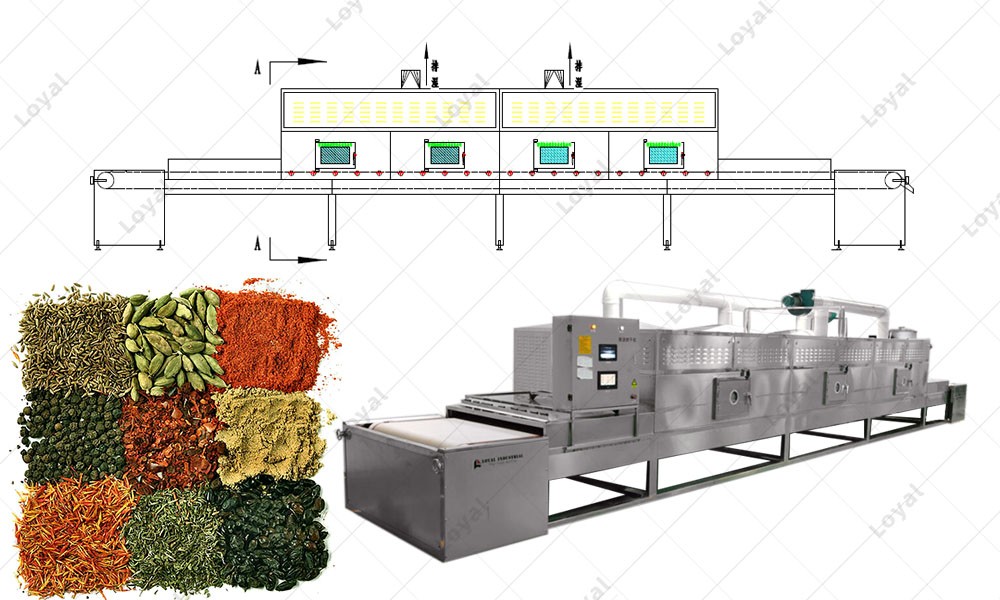

Emergence of Microwave Spices Sterilizer Machines

The emergence of Microwave Spices Sterilizer Machines marks a significant turning point in spice processing. The application of microwave technology has introduced a more efficient and precise sterilization method. This section will provide a historical background, tracing the development of these machines, and emphasize their impact on revolutionizing the spice processing industry. Key milestones and innovations in microwave technology will be highlighted.

Cutting-edge Technological Innovations

This section provides an in-depth exploration of the latest innovations in Microwave Spices Sterilizer Machines. These cutting-edge technologies contribute to heightened precision, accelerated processing speeds, and an overall improvement in the efficacy of spice sterilization. Case studies exemplify successful implementations in real-world scenarios.

Future Trends in Microwave Spices Sterilizer Machine Technology

Anticipating the future unfolds a landscape where Microwave Spices Sterilizer Machines seamlessly integrate artificial intelligence, automation, and smart features. This section explores how these advancements are poised to revolutionize spice processing, making it more streamlined, adaptive, and efficient.

Sustainability and Environmental Impact

In the quest for sustainable practices, the article will explore how Microwave Spices Sterilizer Machines contribute to environmental conservation. These machines are designed with eco-friendly features, including reduced energy consumption and waste generation. The discussion will cover the environmental benefits of adopting this advanced technology, emphasizing its alignment with global sustainability goals.

Adaptability to Industry Demands

As the food processing industry undergoes constant changes and demands, this section will delve into how Microwave Spices Sterilizer Machines adapt to these evolving requirements. Their versatility in accommodating various spice processing needs, scalability options, and potential for customization will be thoroughly examined. Real-world examples and case studies will illustrate the machines' adaptability to different scenarios.

Regulatory Compliance and Safety in Future Technologies

Anticipating future trends, the article will explore the expected regulatory standards and safety measures for the next generation of Microwave Spices Sterilizer Machines. It will discuss the importance of compliance with industry regulations and certifications to ensure the safe and secure implementation of these advanced technologies. This section aims to provide insights into the measures taken to meet global safety standards.

These additional sections will provide a comprehensive exploration of the current landscape, historical emergence, sustainability aspects, adaptability, and regulatory considerations of Microwave Spices Sterilizer Machines, contributing to a holistic understanding of their role in the future of spice processing.

Industry Collaboration and Knowledge Sharing

This section emphasizes the importance of collaboration within the industry, fostering mutual growth and knowledge sharing. Successful case studies highlight instances where collaborative efforts have driven technological leaps in Microwave Spices Sterilizer Machine advancements.

Conclusion

In conclusion, this article summarizes the key advancements discussed, underlining the transformative potential of Microwave Spices Sterilizer Machines in the future of spice processing. The call to action encourages manufacturers to stay informed, embrace emerging trends, and actively contribute to the ongoing evolution of the spice processing landscape.

FAQs: Common Questions about Microwave Spices Sterilizer Machine

In this section, we will address common questions and concerns related to Microwave Spices Sterilizer Machines, providing readers with a clearer understanding of this innovative technology.

Q1: How does a Microwave Spices Sterilizer Machine work?

A: Microwave Spices Sterilizer Machines utilize microwave technology to generate heat within the spices, effectively eliminating bacteria, pathogens, and contaminants. The microwaves penetrate the spices, ensuring uniform sterilization without compromising quality.

Q2: How does this technology compare to traditional spice sterilization methods?

A: Microwave Spices Sterilizer Machines offer several advantages over traditional methods. They are faster, more precise, and environmentally friendly. Unlike heat or steam-based methods, microwave sterilization minimizes processing time and energy consumption while maintaining the integrity of the spices.

Q3: Can Microwave Spices Sterilizer Machines be customized for different spice processing needs?

A: Yes, these machines are designed with adaptability in mind. Manufacturers can customize parameters such as power levels, processing times, and temperature settings to suit various spice types and processing requirements.

Q4: Are Microwave Spices Sterilizer Machines suitable for large-scale spice processing operations?

A: Absolutely. Microwave Spices Sterilizer Machines are scalable and can be integrated into large-scale processing facilities. Their efficiency and speed make them well-suited for meeting the demands of bulk spice production without compromising on quality.

Q5: What is the expected lifespan of Microwave Spices Sterilizer Machines, and do they require frequent maintenance?

A: Microwave Spices Sterilizer Machines are designed for durability and minimal maintenance. The expected lifespan depends on usage and adherence to maintenance schedules. Regular inspections and simple maintenance routines contribute to prolonged equipment life.

Addressing these frequently asked questions will provide readers with valuable insights into the functionality, safety, adaptability, and environmental impact of Microwave Spices Sterilizer Machines.

Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines