- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Company News> Full Automation Mastery: Exploring the Capabilities of the Automatic Microwave Chili Powder Sterilization Machine

Full Automation Mastery: Exploring the Capabilities of the Automatic Microwave Chili Powder Sterilization Machine

2024-01-12 11:36:39Full Automation Mastery: Exploring the Capabilities of the Automatic Microwave Chili Powder Sterilization Machine.At {Shandong Loyal Industrial Co.,Ltd}, we prioritize client success through state-of-the-art solutions that enhance productivity and reliability. Our comprehensive range of fully automated microwave machinery is engineered to meet the evolving needs of diverse industries. We leverage the power of automation to optimize processes, ensuring a seamless and efficient operation that drives excellence in production.

Introduction

Shandong Loyal Industrial Co.,Ltd. a company specializing in manufacturing food processing equipment, headquartered in Shandong Province, China.The company adheres to the concept of "quality first, innovation leads" and is committed to providing high-quality, high-efficiency advanced equipment for the global food industry.We have established long-term cooperative relationships with many well-known food processing companies around the world, providing them with customized solutions. for example:Püschner,Ispecc.

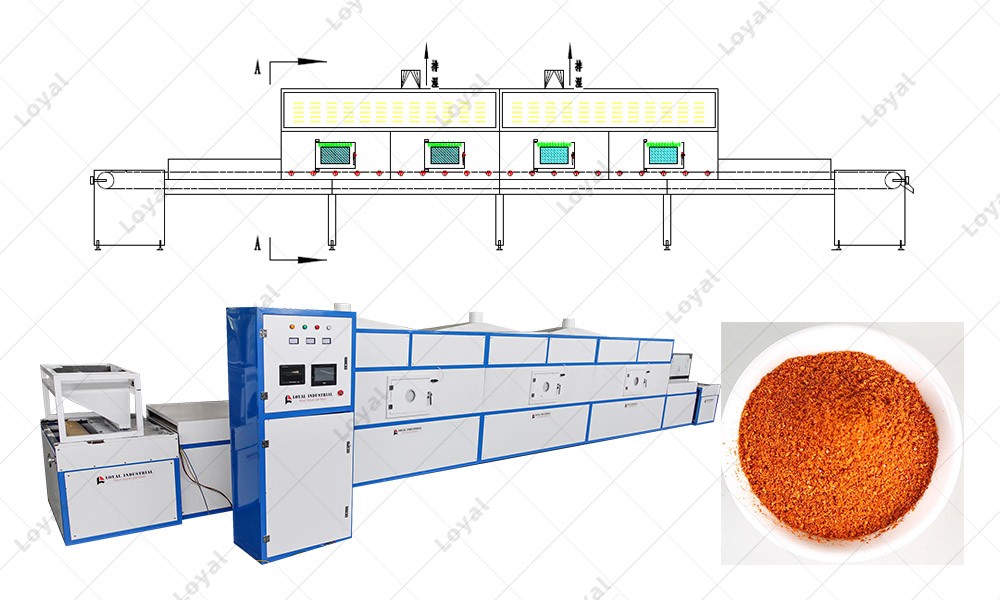

Chili powder sterilization holds immense significance in the food processing industry, ensuring product safety and quality. Traditional sterilization methods, however, face challenges that hinder efficiency. This article delves into the mastery and capabilities of the Automatic Microwave Chili Powder Sterilization Machine, emphasizing its role in achieving full automation and enhancing efficiency in chili powder processing.

Evolution of Chili Powder Sterilization Technologies

With the increasing demands of the food processing industry, there arose a need for more efficient and reliable chili powder sterilization methods. This demand led to the development of heat-based techniques like steam sterilization and dry heat sterilization. While these methods addressed some of the shortcomings of traditional approaches, they still presented challenges in terms of precision, speed, and overall efficiency.

The turning point in chili powder sterilization came with the advent of microwave technology. Microwave sterilization offered a revolutionary approach, leveraging electromagnetic waves to target and eliminate harmful microorganisms in chili powder. This marked the beginning of a new era in the evolution of sterilization technologies.

The Automatic Microwave Chili Powder Sterilization Machine represents the pinnacle of this evolution. Combining the efficiency of microwave technology with fully automated processes, this machine has redefined how chili powder is sterilized in the modern food processing landscape. The evolution from manual, time-consuming methods to highly automated and precise systems showcases the dynamic nature of the chili powder sterilization field

Advanced Features of the Automatic Microwave Chili Powder Sterilization Machine

Detailed insights into the operational features showcase how the fully automatic system significantly improves efficiency in chili powder sterilization. The benefits and advantages of this machine over traditional methods, marked by precision and quality, become evident in this section.

Precision and Quality in Sterilization

This section provides a comprehensive overview of how the fully automatic system ensures precision in the sterilization process. The focus is on understanding the impact on the quality of chili powder products, demonstrating how the technology surpasses traditional methods in maintaining product integrity.

Integration into Chili Powder Processing

Examining the seamless integration of the Automatic Microwave Chili Powder Sterilization Machine into chili powder processing reveals real-world applications and case studies. These examples illustrate increased efficiency and productivity, emphasizing the adaptability of the machine to various stages of chili powder manufacturing.

Advantages and Cost Efficiency

A thorough analysis highlights the economic benefits and cost efficiency for chili powder manufacturers brought about by the fully automatic system. This section outlines how the technology contributes to overall operational excellence and resource optimization.

Technological Innovations and Future Trends

The exploration of ongoing technological innovations in chili powder sterilization sheds light on how the Automatic Microwave Chili Powder Sterilization Machine evolves to meet emerging industry demands. Anticipation of future trends and advancements in chili powder sterilization technology further underscores the machine's forward-looking capabilities.

Environmental Sustainability

An analysis of the environmental impact showcases how the fully automatic system aligns with sustainability goals in food processing. Reduced energy consumption and waste, in comparison to traditional sterilization methods, are key discussion points in this section.

Regulatory Compliance and Safety

This section explores regulatory standards and certifications for the fully automatic system. Discussions delve into the safety measures integrated into the technology, emphasizing industry adherence to quality and safety standards.

Conclusion

The conclusion succinctly summarizes the key points discussed in the article. The emphasis is on how the Automatic Microwave Chili Powder Sterilization Machine masters full automation, contributing to enhanced efficiency in chili powder processing. A call to action urges manufacturers to embrace this advanced technology for elevated productivity and excellence in the food processing industry.

Common Questions about Automatic Microwave Chili Powder Sterilization Machine

1.How does the Automatic Microwave Chili Powder Sterilization Machine differ from traditional methods?

Response: The machine utilizes advanced microwave technology, offering a faster and more precise sterilization process compared to traditional methods like heat or steam. Its automation capabilities contribute to increased efficiency and reduced processing time.

2. What types of chili powder can the machine handle?

Response: The machine is designed to handle various types of chili powder, accommodating different spice levels and particle sizes. Its adaptability allows manufacturers to process a diverse range of chili powder products.

3. Is the sterilization process equally effective for bulk production and small batches?

Response: Yes, the machine ensures uniform sterilization across both bulk production and small batches. Its scalability and precision guarantee consistent results regardless of the processing volume.

4. How does the machine contribute to energy efficiency and sustainability?

Response: The machine incorporates energy-efficient features, such as targeted microwave application and quick processing times, reducing overall energy consumption. Additionally, its precision minimizes waste, aligning with sustainability goals.

5. Does the machine affect the nutritional content of chili powder?

Response: No, the machine's precise sterilization process minimizes heat exposure, preserving the nutritional content of chili powder. This ensures that essential nutrients and flavors remain intact in the final product.

6. What safety measures are in place during the operation of the machine?

Response: The machine adheres to rigorous safety standards and includes automated safety features. Emergency shut-off mechanisms, temperature monitoring, and quality control checkpoints contribute to a secure processing environment.

7. Can the machine be integrated into existing chili powder processing lines?

Response: Yes, the machine is designed for seamless integration into existing processing lines. Its modular structure allows manufacturers to adapt and incorporate it into various stages of chili powder production.

8. Is training required for operators to use the Automatic Microwave Chili Powder Sterilization Machine?

Response: While the machine is user-friendly, training is recommended to ensure optimal operation. Manufacturers can receive comprehensive training on machine functionalities, maintenance, and safety protocols.

Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines