- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Company News> Seamless Thawing Experience: Embracing Full Automation with Energy-Efficient Microwave Defrost for Meat

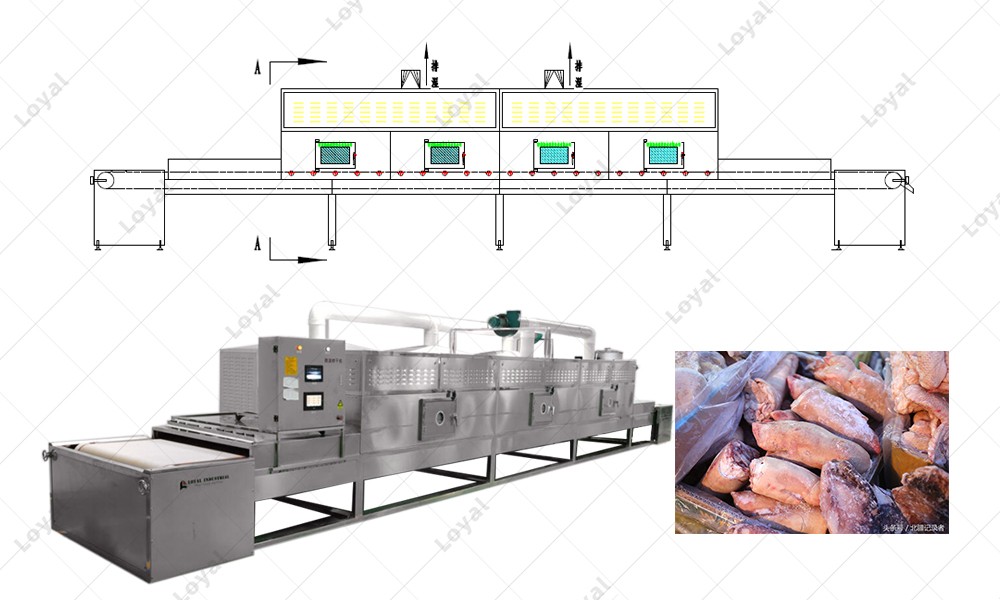

Seamless Thawing Experience: Embracing Full Automation with Energy-Efficient Microwave Defrost for Meat

2024-01-15 16:54:25Seamless Thawing Experience: Embracing Full Automation with Energy-Efficient Microwave Defrost for Meat by {Shandong Loyal Industrial Co.,Ltd} , we provide latest information about the products regularly.

Introduction

Shandong Loyal Industrial Co.,Ltd. a company specializing in manufacturing food processing equipment, headquartered in Shandong Province, China.The company adheres to the concept of "quality first, innovation leads" and is committed to providing high-quality, high-efficiency advanced equipment for the global food industry.We have established long-term cooperative relationships with many well-known food processing companies around the world, providing them with customized solutions. for example:Thermex-Thermatron Systems ,Energy Beam Sciences Inc.

In the realm of modern culinary practices, achieving a seamless thawing experience is pivotal for both professional chefs and home cooks. This article delves into the significance of seamless thawing, introducing microwave technology as a transformative tool for defrosting meat. Emphasis is placed on the crucial role of full automation and energy efficiency in elevating the thawing process.

The Evolution of Microwave Defrosting

A historical perspective on the use of microwaves for thawing sets the stage for understanding the evolution of this culinary practice. From its inception to the present, advancements have led to full automation in meat defrosting. The narrative highlights how energy efficiency has been a driving force in shaping modern microwave technologies, transforming them into indispensable tools in the kitchen.

Unveiling Full Automation in Microwave Defrost for Meat

This section explores the fully automatic features integrated into modern microwaves, unraveling how they enhance the meat thawing experience. By understanding the intricate details of full automation, readers gain insights into the seamless intersection of technology, convenience, and energy savings in the culinary realm.

Setting the Right Parameters: Optimal Microwave Settings for Meat Thawing

Precision in meat thawing begins with setting the right parameters. This segment guides readers in selecting the defrost or low power setting for optimal results. When defrosting meat in a microwave, it's crucial to use settings specifically designed for this purpose. The defrost setting allows for a gradual increase in power, preventing the outer layers of the meat from cooking while promoting efficient thawing. Alternatively, the low power setting can also be effective, providing a controlled environment for a slower thawing process that maintains the integrity of the meat's texture.

Time considerations are paramount and are contingent on both the type of meat and its quantity. For example, delicate cuts like fish or minced meat may require less time, while larger cuts or dense meats may need more time to ensure thorough thawing. The article will delve into specific guidelines for various meats, offering readers a comprehensive understanding of the optimal time settings for their specific culinary needs.

Leveraging microwave wattage is another essential aspect of achieving efficient and thorough thawing. Different microwaves come with varying power levels, and understanding how to adjust the wattage ensures that the meat thaws evenly without any risk of partial cooking. This section will provide insights into how readers can align their microwave's wattage with the type and quantity of meat, empowering them to utilize their kitchen appliances to their full potential.

Ensuring Consistency: Strategies for Uniform Thawing

Consistency is key in achieving perfectly thawed meat. Techniques such as turning and rotating are outlined to distribute heat evenly, preventing any areas from becoming too warm during the thawing process. Turning the meat at regular intervals ensures that all sides receive an equal share of the microwave's energy, promoting uniform thawing from the center to the outer layers.

Additionally, arrangement methods are discussed to avoid uneven thawing, showcasing how full automation plays a vital role in maintaining uniformity throughout the thawing process. Some modern microwaves come equipped with turntables or rotating platforms, ensuring that the meat is constantly in motion during the thawing process. This eliminates the need for manual intervention, providing a truly automated and consistent thawing experience. Readers will gain insights into how these features contribute to the overall efficiency and reliability of the microwave thawing process.

Energy Efficiency and Environmental Impact

This segment evaluates the energy efficiency of microwave defrosting for meat, comparing it with traditional thawing methods. The article underscores the contributions to sustainability through energy-efficient practices, aligning with the global movement toward environmentally conscious culinary habits. It will delve into specific data and comparisons, highlighting how microwave defrosting reduces energy consumption compared to conventional methods.

Furthermore, the environmental impact of microwave defrosting, including reduced carbon footprint and conservation of resources, will be explored. By adopting energy-efficient practices in the kitchen, individuals can actively contribute to a more sustainable future. The article will encourage readers to make informed choices, not only for the sake of convenience but also in alignment with their commitment to environmentally friendly culinary practices.

Addressing Myths and Realities: Common Questions About Microwave Meat Defrosting

Dispelling myths surrounding microwave defrosting is essential for building confidence in its adoption. Common questions are addressed, safety measures are clarified, and a delicate balance between speed and safety is emphasized in the full automation process.

Real-life experiences from users form a compelling narrative, showcasing the ease and efficiency of microwave thawing. Positive feedback on energy savings and time efficiency provides authentic testimony, complemented by practical tips and recommendations for maximizing the benefits of full automation.

The Future of Microwave Defrosting: Innovations and Trends

The exploration of ongoing innovations in microwave appliances sets the stage for envisioning the future of meat thawing. Integrating smart technologies for enhanced automation and predicting upcoming trends anticipates an even more seamless thawing experience.

Common Questions about Defrosting Meat in Microwave

1. Is fully automatic microwave defrosting safe for all types of meat?

Absolutely. When following recommended settings, fully automatic microwave defrosting is safe and efficient for various types of meat.

2. How does it compare to traditional thawing methods in terms of energy consumption?

Fully automatic microwave defrosting significantly reduces energy consumption compared to traditional methods, contributing to a more environmentally friendly kitchen.

3. Can I defrost large quantities of meat at once?

Yes, the step-by-step guide provides insights into adjusting settings based on the quantity of meat. Microwave defrosting is versatile and can accommodate various quantities with ease.

4. Does it compromise the quality of meat?

No, fully automatic microwave defrosting preserves the natural quality of meat by ensuring a rapid and uniform thawing process.

Conclusion

Fully automatic microwave defrosting has elevated the culinary experience, offering high efficiency, energy savings, and unparalleled convenience. As technology continues to advance, the kitchen landscape is reshaped, with this method standing at the forefront of innovation. Whether you are a seasoned chef or a home cook, embracing this transformative approach to meat thawing is a step towards a more efficient, sustainable, and delightful kitchen journey.

Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines