- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Company News> Everything you Need to Know About Fish Food Making Machine

Everything you Need to Know About Fish Food Making Machine

2024-04-19 14:46:19Introduction to Fish Food Making Machines

Fish food making machines are specialized equipment designed for the efficient production of fish feed pellets or flakes. These machines play a crucial role in the aquaculture industry by automating the process of preparing nutritionally balanced feed for various species of fish. Utilizing advanced technology and precise engineering, fish food making machines ensure consistent quality and optimize the feeding efficiency of fish farms.

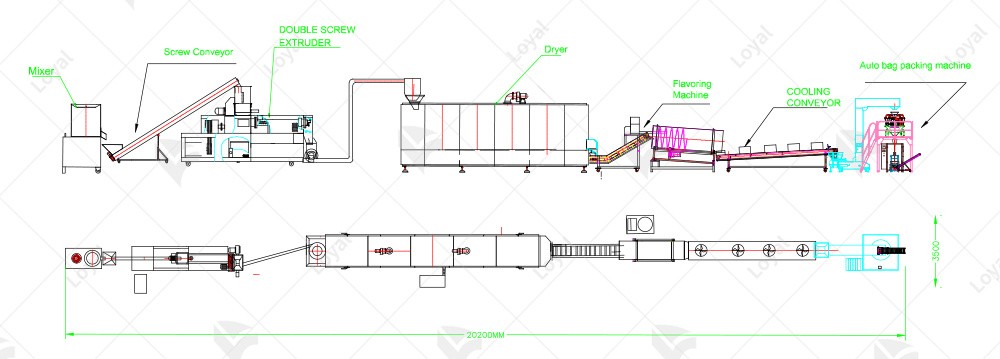

Fish food making machines typically consist of several key components, including a mixer, extruder, dryer, and cutter. The mixer blends different ingredients such as fish meal, grains, vitamins, and minerals to create a homogenous feed mixture. The extruder processes the mixture into uniform pellets or flakes, while the dryer removes moisture to enhance shelf life. Finally, the cutter shapes the feed into the desired size for easy consumption by fish.

Types of Fish Food Making Machines Available

There are several types of fish food making machines available on the market, each catering to specific production requirements and output capacities. One common type is the single-screw extruder, which is suitable for small to medium-scale operations. These extruders are versatile and can produce a wide range of fish feed formulations with consistent quality.

For larger-scale fish farms or industrial applications, twin-screw extruders are preferred due to their higher throughput and enhanced processing capabilities. These machines offer greater flexibility in terms of feed formulation and can accommodate a variety of ingredients, including raw materials with high moisture content.

In addition to extruders, there are also specialized machines for producing sinking or floating fish feed pellets. Sinking feed pellets are designed to sink quickly to the bottom of the water, making them suitable for bottom-feeding fish species. On the other hand, floating feed pellets remain buoyant on the water surface, making them ideal for fish that prefer to feed near the surface.

Overall, the choice of fish food making machine depends on factors such as production volume, feed formulation requirements, and budget constraints. By selecting the right type of machine, fish farmers can optimize feed production efficiency and contribute to the sustainable growth of their aquaculture operations.

Key Components and Features of Fish Food Making Machines

Key Components and Features of Fish Food Making Machines

Fish food making machines are sophisticated pieces of equipment designed to streamline the production process of fish feed. These machines consist of several key components and offer various features to ensure efficient and high-quality production. Let's delve into the essential components and features of fish food making machines.

The first crucial component of fish food making machines is the extruder. This device is responsible for the primary process of creating fish feed pellets. Extruders come in different types, such as single-screw and twin-screw extruders, each offering specific advantages in terms of production capacity and pellet quality. Additionally, modern extruders are equipped with advanced controls for precise temperature and pressure regulation, ensuring optimal cooking and shaping of the feed.

Another important component is the feeder system, which accurately delivers the raw materials into the extruder. Fish food making machines often feature gravimetric or volumetric feeders that can handle a wide range of ingredients, including fish meal, grains, vitamins, and minerals. These feeders ensure consistent ingredient proportions and contribute to the uniformity of the final fish feed pellets.

Furthermore, fish food making machines are equipped with cutting and shaping mechanisms to produce pellets of the desired size and shape. High-speed rotating blades or die plates are commonly used to cut the extruded feed into uniform pellets, which are then dried and cooled to enhance shelf life and stability.

In terms of features, modern fish food making machines boast several advancements aimed at improving efficiency and productivity. Automated control systems allow operators to monitor and adjust processing parameters in real time, ensuring optimal performance and minimal downtime. Additionally, some machines are equipped with self-cleaning mechanisms to facilitate maintenance and prevent cross-contamination between batches.

Process of Fish Food Production Using Machines

The process of fish food production using machines involves several steps, each crucial for the creation of high-quality fish feed pellets. Let's explore the typical process followed in fish food production using machines.

The first step in fish food production is the preparation of raw materials. This involves sourcing high-quality ingredients such as fish meal, grains, soybean meal, vitamins, and minerals. The raw materials are then carefully weighed and mixed according to specific formulations to meet the nutritional requirements of the target fish species.

Once the ingredients are prepared, they are fed into the fish food making machine using the feeder system. The machine's extruder processes the raw materials by cooking, shaping, and compressing them into compact pellets. The extrusion process not only cooks the ingredients to eliminate harmful bacteria but also enhances the digestibility and palatability of the feed.

After extrusion, the freshly formed pellets are cut to the desired size and shape using cutting blades or die plates. The pellets are then conveyed to a drying chamber where they undergo thermal drying to reduce moisture content and improve shelf stability. Finally, the dried pellets are cooled and sieved to remove any fines or irregularly shaped pellets before packaging.

Throughout the production process, strict quality control measures are implemented to ensure the safety, integrity, and nutritional quality of the fish feed pellets. Operators monitor processing parameters such as temperature, pressure, and moisture levels to maintain consistency and optimize production efficiency.

Benefits of Using Fish Food Making Machines

Benefits of Using Fish Food Making Machines

1. Enhanced Efficiency: Fish food making machines automate various stages of the feed production process, including mixing, grinding, extruding, and drying. This automation significantly reduces manual labor requirements and speeds up production, allowing manufacturers to produce larger quantities of fish feed in less time.

2. Consistent Quality: Fish food making machines ensure uniform mixing and blending of ingredients, resulting in fish feed with consistent texture, size, and nutritional content. This consistency is essential for promoting healthy fish growth and maximizing feed conversion ratios.

3. Customization Options: Many fish food making machines offer adjustable settings and interchangeable components, allowing manufacturers to customize the feed formulation according to the nutritional needs of different fish species and growth stages. This flexibility enables producers to meet the specific dietary requirements of their target market segments.

4. Cost Savings: By streamlining the production process and minimizing waste, fish food making machines help reduce overall production costs. Additionally, the ability to control ingredient ratios and minimize the use of expensive additives can further contribute to cost savings over time.

5. Improved Hygiene and Safety: Fish food making machines are designed with hygiene and safety in mind, featuring easy-to-clean surfaces, sanitary construction materials, and built-in safety mechanisms. This ensures that the final fish feed products meet regulatory standards and are safe for consumption by fish.

Factors to Consider When Choosing a Fish Food Making Machine

Factors to Consider When Choosing a Fish Food Making Machine

1. Production Capacity: Determine the desired production volume of fish feed per day or per batch to select a machine with the appropriate capacity. Consider factors such as market demand, facility size, and growth projections.

2. Versatility: Evaluate the machine's ability to produce a wide range of fish feed formulations, including pellets, flakes, and granules. Versatile machines offer greater flexibility to adapt to changing market demands and fish species requirements.

3. Quality and Reliability: Choose a fish food making machine from reputable manufacturers known for producing high-quality, durable equipment. Read customer reviews, request product demonstrations, and inquire about warranty and after-sales support options.

4. Energy Efficiency: Assess the energy consumption of the machine and look for features such as energy-efficient motors, insulation, and programmable controls to minimize operational costs and environmental impact.

5. Ease of Maintenance: Consider the ease of cleaning, maintenance, and repair of the machine, as regular upkeep is essential for maximizing uptime and prolonging equipment lifespan. Look for machines with accessible components, user-friendly interfaces, and comprehensive maintenance manuals.

6. Cost: Compare the upfront cost of the machine with its long-term value proposition, factoring in factors such as production efficiency, reliability, and total cost of ownership. Request quotes from multiple suppliers and evaluate the return on investment over time.

LOYAL Company vs. NP Company: A Simple Comparison

LOYAL Company vs. NP Company: A Simple Comparison

|

Aspect |

LOYAL Company's Machine |

NP Company's Machine |

|

Production Capacity |

Higher capacity |

Lower capacity |

|

Versatility |

Moderate |

High |

|

Quality and Reliability |

Excellent |

Good |

|

Energy Efficiency |

Energy-efficient |

Standard |

|

Maintenance |

Easy to maintain |

Requires expertise |

|

Cost |

Higher upfront cost |

Lower upfront cost |

In summary, both LOYAL Company and NP Company offer fish food making machines with unique features and capabilities. The choice between the two will depend on specific production requirements, budget constraints, and preferences for quality, reliability, and efficiency.

Maintenance and Cleaning of Fish Food Making Machines

Maintenance and Cleaning of Fish Food Making Machines

Regular maintenance is crucial to keep fish food making machines in good working condition. This includes inspecting and lubricating moving parts, checking for wear and tear, and replacing worn-out components as needed. Additionally, scheduled maintenance tasks such as calibration of equipment, alignment checks, and software updates should be performed according to the manufacturer's guidelines.

Cleaning fish food making machines is paramount to prevent cross-contamination and ensure product quality and safety. Before cleaning, it's essential to follow proper shutdown procedures and disconnect the machine from power sources to prevent accidents.

Using approved cleaning agents and sanitizers, thoroughly clean all surfaces, including conveyor belts, hoppers, extruders, and cutting blades, to remove residue, oils, and debris. Pay special attention to hard-to-reach areas where bacteria and pathogens may accumulate.

After cleaning, rinse all components thoroughly with clean water to remove any remaining cleaning agents. Allow the machine to dry completely before reassembling and restarting operations. Implementing a regular cleaning schedule and documenting cleaning procedures is vital to comply with food safety regulations and maintain hygienic standards.

Cost Analysis of Fish Food Making Machines

Cost Analysis of Fish Food Making Machines

The initial cost of fish food making machines can vary depending on factors such as machine type, capacity, features, and brand reputation. Higher-capacity machines with advanced features may command a higher upfront investment but offer greater efficiency and productivity in the long run.

In addition to the purchase price, operating costs such as electricity, water, and labor should be factored into the cost analysis. Energy-efficient machines may incur lower operating expenses over time, leading to cost savings.

Maintenance and repair costs are also essential considerations. Regular maintenance helps prevent costly breakdowns and prolongs the lifespan of the equipment. However, unexpected repairs or replacement of parts may incur additional expenses.

Furthermore, it's essential to assess the return on investment (ROI) of fish food making machines based on factors such as increased production capacity, improved product quality, reduced labor costs, and market demand for fish food products. Conducting a thorough cost-benefit analysis will help determine the financial viability of investing in fish food making machines for your business.

Innovations and Advancements in Fish Food Making Machine Technology

One key innovation is the development of multi-functional fish food making machines that can perform various tasks in the production process. These machines integrate functions such as mixing, grinding, extrusion, and shaping into a single unit, streamlining operations and reducing the need for multiple pieces of equipment. By consolidating processes, manufacturers can achieve greater efficiency and productivity while minimizing space and labor requirements.

Another notable advancement is the incorporation of digitalization and automation into fish food making machines. Modern machines are equipped with advanced control systems, sensors, and monitoring devices that enable precise control over processing parameters such as temperature, moisture, and pressure. Automation features allow for real-time adjustments and optimization of production processes, resulting in consistent product quality and reduced downtime.

Furthermore, there has been a focus on improving the hygienic design and material selection of fish food making machines to meet the highest standards of food safety and sanitation. Stainless steel construction, smooth surfaces, and removable parts facilitate thorough cleaning and disinfection, minimizing the risk of contamination and ensuring compliance with regulatory requirements.

Future Trends in Fish Food Making Machine Industry

Future Trends in Fish Food Making Machine Industry

Looking ahead, several trends are expected to shape the future of the fish food making machine industry, driven by technological advancements, market demand, and sustainability concerns.

One trend is the continued development of environmentally friendly and energy-efficient fish food making machines. Manufacturers are exploring alternative energy sources, such as solar and biomass, to power machines and reduce carbon emissions. Additionally, there is a growing emphasis on reducing water usage and waste generation in fish food production processes through innovative technologies and practices.

Another trend is the integration of artificial intelligence (AI) and machine learning algorithms into fish food making machines to enhance process control, predictive maintenance, and product quality optimization. AI-powered systems can analyze data from sensors and production metrics to identify patterns, detect anomalies, and recommend adjustments in real-time, improving overall efficiency and performance.

Furthermore, there is increasing interest in customization and personalization capabilities in fish food making machines to meet the diverse needs and preferences of consumers. Machines equipped with flexible production lines and customizable settings enable manufacturers to produce a wide range of fish food products tailored to specific species, nutritional requirements, and market segments.

Overall, the future of the fish food making machine industry is poised for continued innovation and growth, driven by technological advancements, market dynamics, and the imperative to meet evolving consumer demands while ensuring sustainability and food safety.

References

1. Food and Agriculture Organization of the United Nations (FAO): https://www.fao.org/home/en/

2. American Society of Agricultural and Biological Engineers (ASABE): https://www.asabe.org/

3. The Aquaculture Engineering Society (AES): https://www.aesweb.org/

4. European Aquaculture Society (EAS): https://www.aquaeas.eu/

5. International Aquafeed Magazine:https://www.international-aquafeed.com/

Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines