- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Company News> The Ultimate Pet Food Machine Guide to 2024

The Ultimate Pet Food Machine Guide to 2024

2024-04-24 16:05:28Introduction to Pet Feed Machines

Pet feed machines are sophisticated pieces of equipment designed to streamline the process of manufacturing pet food on an industrial scale. These machines play a crucial role in the pet food industry, ensuring efficiency, consistency, and quality in the production process.

The utilization of pet feed machines has revolutionized the pet food industry, enabling manufacturers to meet the growing demand for high-quality pet food while maintaining cost-effectiveness and compliance with regulatory standards. These machines offer precise control over ingredient proportions, cooking temperatures, and production rates, ensuring the consistency and safety of the final product.

In recent years, advancements in technology have led to the development of highly automated pet feed machines equipped with intelligent monitoring systems and data analytics capabilities. These features enhance operational efficiency, minimize downtime, and optimize resource utilization, further driving the evolution of the pet food manufacturing industry.

Pet feed machines are indispensable assets for pet food manufacturers seeking to deliver nutritious, safe, and appealing products to pets worldwide. With their efficiency, versatility, and reliability, these machines continue to play a pivotal role in shaping the future of the pet food industry.

Types of Pet Feed Machines

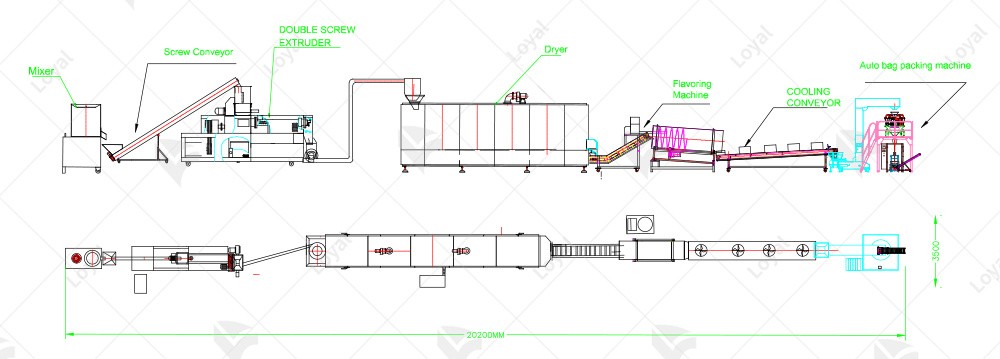

1. Mixers: Mixers are essential components of pet feed production lines, responsible for blending various ingredients to create homogeneous mixtures. They come in different configurations, including ribbon mixers, paddle mixers, and twin-shaft mixers, each offering distinct advantages in terms of mixing efficiency and consistency.

2. Extruders: Extruders are versatile machines used to process and shape pet food formulations into specific sizes and shapes. They employ high-pressure and high-temperature conditions to cook and expand ingredients, resulting in uniform textures and enhanced digestibility. Single-screw and twin-screw extruders are commonly utilized in pet feed manufacturing, offering flexibility in processing different types of ingredients and achieving desired product characteristics.

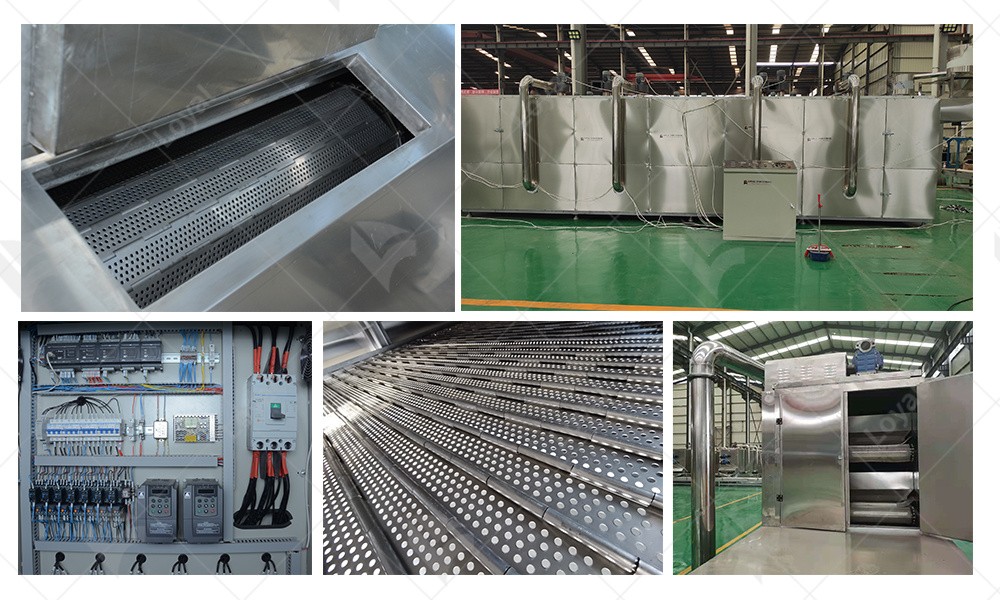

3. Dryers: Dryers play a critical role in the pet feed production process by removing moisture from extruded or cooked products to enhance shelf life and prevent microbial growth. Various types of dryers, such as belt dryers, fluidized bed dryers, and rotary dryers, are employed based on the specific requirements of the pet food formulation and production volume.

4. Packaging Systems: Packaging systems ensure the efficient and hygienic packaging of pet food products for distribution and retail. These systems encompass filling machines, sealing machines, and labeling machines, designed to accommodate different packaging formats, including bags, cans, and pouches. Advanced packaging systems may incorporate automation and integration with upstream production processes to optimize throughput and minimize product waste.

Pet feed machines are available in a range of configurations and capacities to suit the diverse needs of pet food manufacturers, from small-scale operations to large-scale production facilities. By selecting the appropriate combination of machines and optimizing production workflows, manufacturers can achieve cost-effective and sustainable pet food manufacturing processes while meeting consumer demand for high-quality and nutritious pet products.

Factors to Consider When Choosing a Pet Feed Machine

When it comes to selecting the right pet feed machine for your business, several factors need careful consideration. Two prominent players in the market, LOYAL and Buhler, offer competitive machines with distinct features. Let's compare them across various aspects in a simple tabular format.

|

Factors |

LOYAL Pet Feed Machine |

Buhler Pet Feed Machine |

|

Capacity |

LOYAL machines typically offer a moderate capacity, suitable for small to medium-sized operations. |

Buhler machines are known for their high capacity, catering to large-scale production needs. |

|

Production Efficiency |

LOYAL machines are efficient for consistent output in smaller batches, ensuring quality control. |

Buhler machines boast exceptional efficiency, capable of handling large volumes swiftly. |

|

Flexibility in Ingredients |

LOYAL machines provide decent flexibility for incorporating various ingredients and formulations. |

Buhler machines offer extensive flexibility, accommodating a wide range of ingredients and recipes. |

|

Automation and Control Systems |

LOYAL machines come equipped with standard automation features and user-friendly controls. |

Buhler machines excel in automation, with advanced control systems for precise operation and monitoring. |

|

Sanitation and Cleaning |

LOYAL machines are designed with easy-to-clean components, suitable for routine maintenance. |

Buhler machines prioritize sanitation, featuring innovative cleaning mechanisms to ensure food safety standards. |

|

Durability and Reliability |

LOYAL machines are reliable for consistent performance, though they may have slightly shorter lifespans compared to industrial giants. |

Buhler machines are renowned for their robust build and long-term reliability, ideal for heavy-duty usage. |

|

Cost Analysis |

LOYAL machines offer competitive pricing, making them accessible for small to mid-sized businesses with budget constraints. |

Buhler machines represent a significant investment upfront but provide excellent value over time for large-scale enterprises. |

|

User-Friendly Interface |

LOYAL machines feature intuitive interfaces, suitable for operators with basic training. |

Buhler machines prioritize user experience, with ergonomic designs and comprehensive training programs. |

In summary, while LOYAL and Buhler both offer commendable pet feed machines, the choice ultimately depends on specific business requirements, budget considerations, and the scale of production operations.

Key Components and Features of Modern Pet Feed Machines

One of the primary components of modern pet feed machines is the mixing chamber or hopper, where raw ingredients are combined to create the desired pet food formula. These chambers are equipped with precision mixing mechanisms, such as augers or paddle mixers, to ensure thorough blending of ingredients. Additionally, some machines feature multiple chambers for mixing different ingredients simultaneously, allowing for greater recipe flexibility and customization.

Another essential component is the extrusion system, which shapes the blended ingredients into the final pet food product. Extruders utilize high pressure and temperature to cook the mixture and form it into the desired shape, whether it be kibble, pellets, or treats. Advanced extrusion systems offer adjustable settings for temperature, pressure, and die shape, allowing manufacturers to achieve precise control over product characteristics such as texture, density, and moisture content.

Pet feed machines also incorporate various automation and control features to streamline operations and optimize production efficiency. These may include programmable PLC (Programmable Logic Controller) systems, touchscreen interfaces, and integrated sensors for monitoring parameters such as temperature, moisture, and production rate. Additionally, some machines are equipped with self-cleaning mechanisms and remote monitoring capabilities, reducing downtime and maintenance requirements.

Modern pet feed machines prioritize hygiene and sanitation to ensure the safety and quality of the final product. Many models are constructed from stainless steel or other food-grade materials that are easy to clean and resistant to corrosion. In addition to regular cleaning protocols, some machines feature CIP (Clean-in-Place) systems that automate the cleaning process, minimizing manual intervention and cross-contamination risks.

Trends in Automated Pet Food Production

One prominent trend is the integration of IoT (Internet of Things) technology into pet feed machines, enabling real-time monitoring and data analysis of production processes. IoT-enabled machines are equipped with sensors and connectivity features that gather information on variables such as ingredient levels, equipment performance, and product quality. This data can be analyzed to optimize production efficiency, detect and prevent issues, and ensure consistency in product quality.

Another significant trend is the rise of customized and personalized pet food solutions, driven by consumer demand for tailored nutrition and ingredient transparency. Automated systems are being developed to facilitate the formulation and production of customized pet food recipes based on factors such as age, breed, dietary restrictions, and health conditions. These systems utilize data analytics and AI (Artificial Intelligence) algorithms to recommend optimal formulations and adjust production parameters accordingly.

Additionally, sustainability is becoming an increasingly important consideration in automated pet food production. Manufacturers are adopting eco-friendly practices and technologies to reduce waste, conserve resources, and minimize environmental impact. This includes the use of renewable energy sources, recyclable packaging materials, and efficient production processes that optimize resource utilization and minimize emissions.

Automation and robotics are transforming various aspects of pet food production, from ingredient handling and processing to packaging and palletizing. Robotic systems offer precision, speed, and flexibility in tasks such as sorting, weighing, mixing, and packaging, reducing labor costs and improving productivity. Advanced robotics also enable the implementation of lean manufacturing principles, allowing for efficient use of space and resources in production facilities.

Quality Control in Pet Feed Machine Operations

One essential aspect of quality control is the selection and testing of raw materials used in pet food formulations. Manufacturers must source high-quality ingredients that meet nutritional specifications and comply with safety standards. This involves rigorous testing for contaminants, adulterants, and allergens, as well as monitoring for factors such as moisture content, freshness, and nutritional value.

Once ingredients are received, they undergo thorough inspection and quality checks before being introduced into the production process. This may include visual inspection for signs of damage or contamination, as well as laboratory testing for microbiological safety and nutritional composition. Any deviations from quality standards are promptly addressed to prevent compromised product quality.

During the mixing and extrusion phases of production, quality control measures are implemented to ensure uniformity and consistency in the final product. This involves monitoring parameters such as temperature, pressure, mixing time, and moisture content to optimize processing conditions and achieve desired product characteristics. Automated systems may be utilized to maintain precise control over these variables and detect deviations in real-time.

In addition to in-process monitoring, finished products undergo comprehensive quality assurance testing to verify compliance with specifications and standards. This includes analysis of physical attributes such as texture, color, and size, as well as nutritional analysis to confirm adherence to formulation requirements. Samples are also subjected to microbiological testing to detect any potential contaminants or pathogens.

Sustainability Practices in Pet Food Manufacturing

Sustainability has become a key focus in the pet food manufacturing industry, with companies increasingly adopting environmentally friendly practices. Pet feed Machine manufacturers play a crucial role in this endeavor by designing equipment that minimizes waste, energy consumption, and environmental impact.

One of the primary ways pet feed Machine contribute to sustainability in pet food manufacturing is through efficient resource utilization. These machines are designed to optimize ingredient usage, reducing waste and ensuring that every component of the feed is utilized effectively. Additionally, advanced pet feed Machine incorporate technologies such as precision mixing and portion control, further minimizing waste throughout the production process.

Another aspect of sustainability addressed by pet feed Machine is energy efficiency. Manufacturers are developing machines that consume less energy while maintaining high levels of productivity. This not only reduces operating costs for pet food manufacturers but also lessens the environmental footprint associated with energy consumption.

Furthermore, pet feed Machine manufacturers are increasingly incorporating sustainable materials and production methods into their designs. This includes using recycled materials in machine construction, as well as implementing eco-friendly manufacturing processes. By prioritizing sustainability in their operations, these manufacturers are contributing to the overall sustainability of the pet food manufacturing industry.

Market Analysis: Global Landscape of Pet Food Machine Industry

The global pet food machine industry is experiencing steady growth, driven by the rising demand for high-quality pet food products worldwide. Pet feed Machine manufacturers are capitalizing on this trend by introducing innovative technologies and expanding their product offerings to meet the diverse needs of pet food manufacturers across the globe.

One of the key factors driving the growth of the pet food machine industry is the increasing pet ownership rates, particularly in emerging markets. As more households welcome pets into their families, the demand for pet food products continues to rise, driving the need for advanced manufacturing equipment.

Another significant trend shaping the global landscape of the pet food machine industry is the growing focus on customization and flexibility. Pet food manufacturers are seeking machines that offer the ability to produce a wide range of products to cater to different dietary preferences and nutritional needs of pets. Consequently, pet feed Machine manufacturers are investing in research and development to enhance the versatility and adaptability of their machines.

Technological advancements such as automation, robotics, and artificial intelligence are transforming the pet food manufacturing process. These innovations improve efficiency, accuracy, and consistency in production, driving the adoption of advanced pet feed Machine across the industry.

Future Prospects and Innovations in Pet Feed Machine Technology

Looking ahead, the future of pet feed Machine technology holds exciting possibilities for further innovation and advancement. Manufacturers are continually exploring new ways to improve efficiency, enhance product quality, and reduce environmental impact through the development of cutting-edge technologies.

One area of innovation in pet feed Machine technology is the integration of smart sensors and IoT (Internet of Things) capabilities. These technologies enable real-time monitoring and control of machine performance, allowing for predictive maintenance and optimization of production processes. By leveraging data-driven insights, pet feed Machine can operate more efficiently and reliably, ultimately reducing downtime and maximizing productivity.

Another promising development in pet feed Machine technology is the application of 3D printing. Manufacturers are exploring the use of 3D printing to produce customized components and spare parts for pet feed Machine, streamlining the manufacturing process and reducing lead times. Additionally, 3D printing allows for the creation of complex geometries and lightweight structures, further enhancing the performance and functionality of pet feed Machine.

In conclusion, the future of pet feed Machine technology is bright, with ongoing advancements in smart technologies, 3D printing, and renewable energy promising to revolutionize the pet food manufacturing industry. By embracing innovation and sustainability, pet feed Machine manufacturers are well-positioned to drive growth and competitiveness in the evolving pet food market.

References

1. Petfoodindustry.com

Website: https://www.petfoodindustry.com/

2. Buhlergroup.com

Website: https://www.buhlergroup.com/

3. Clextral.com

Website:https://www.clextral.com/

4. Gea.com

Website: https://www.gea.com/

5. Andritz.com

Website: https://www.andritz.com/

Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines