- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Company News> The Ultimate Guide to Microwave Drying Equipment in 2024

The Ultimate Guide to Microwave Drying Equipment in 2024

2024-04-25 14:20:30Introduction

Microwave drying equipment stands at the forefront of innovation in the food processing industry, offering unparalleled efficiency and precision in moisture removal. In this comprehensive guide to microwave drying equipment in 2024, we delve into its working principles, applications across various industries, technological advancements, challenges, and future outlook. As experts in the field, we aim to provide valuable insights into the transformative capabilities of microwave drying equipment and its pivotal role in shaping the landscape of food processing. Join us as we explore the ultimate guide to microwave drying equipment, offering a detailed understanding of its significance and potential in the year 2024 and beyond.

Working Principle of Microwave Drying Equipment

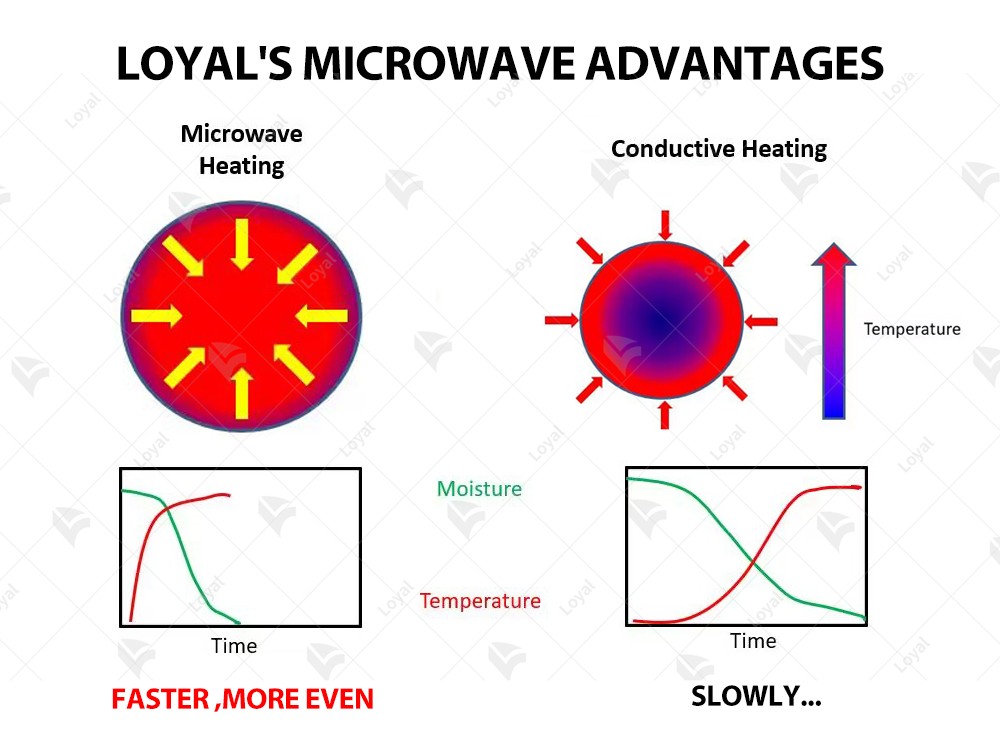

Microwave drying equipment operates on the principle of utilizing electromagnetic waves to generate heat within the product being dried. Unlike conventional drying methods that rely on convection or conduction, microwave drying relies on the direct absorption of microwave energy by water molecules present in the product.

When microwave energy is applied to the product, the water molecules within it absorb the energy and begin to oscillate rapidly. This rapid oscillation generates heat, which in turn causes the water molecules to evaporate, thereby drying the product. The entire process occurs rapidly and efficiently, leading to reduced drying times compared to traditional methods.The microwave generator produces electromagnetic waves at a specific frequency, typically in the range of 300 MHz to 300 GHz, which are then transmitted through the waveguide into the drying chamber.

Within the drying chamber, the product is evenly exposed to the microwave energy, ensuring uniform heating and drying. Temperature and humidity sensors may be incorporated into the equipment to monitor and control the drying process, ensuring optimal results.

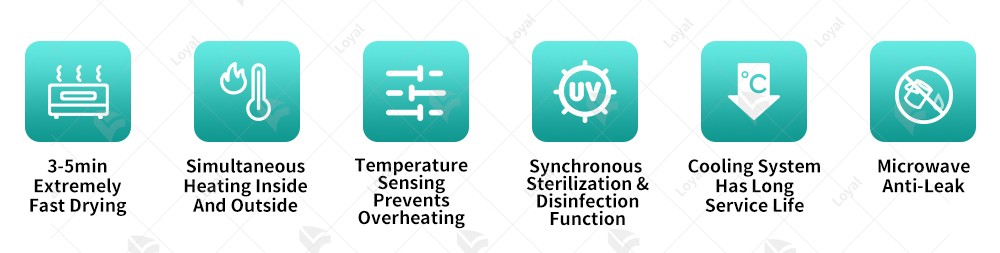

Advantages of Microwave Drying Equipment

Microwave drying equipment offers numerous advantages over traditional drying methods, revolutionizing the food processing industry and beyond. Below is a concise summary of the key advantages of microwave drying equipment:

|

Advantages of Microwave Drying Equipment |

|

1. Rapid Drying |

|

Microwave drying equipment enables rapid drying times, significantly reducing processing time compared to conventional methods. This increased efficiency allows for higher throughput and shorter production cycles. |

|

2. Improved Product Quality |

|

The gentle heating mechanism of microwave drying preserves the natural flavors, colors, and nutrients of the food products. This results in higher-quality end products with better texture, taste, and nutritional value. |

|

3. Uniform Heating |

|

Unlike conventional drying methods that may cause uneven heating, microwave drying equipment provides uniform heating throughout the product. This ensures consistent moisture removal and prevents over-drying or under-drying of the material. |

|

4. Energy Efficiency |

|

Microwave drying equipment typically consumes less energy compared to traditional drying methods. The targeted heating process minimizes heat loss and reduces overall energy consumption, resulting in cost savings and environmental benefits. |

|

5. Versatility |

|

Microwave drying equipment is versatile and can be used for a wide range of food products, including fruits, vegetables, meats, grains, and herbs. It offers flexibility in processing various materials with different moisture contents and shapes. |

|

6. Controllable Process |

|

With precise control over temperature, power, and time settings, microwave drying equipment allows operators to tailor the drying process to specific requirements. This level of control ensures consistent results and minimizes product variability. |

|

7. Reduced Labor Requirements |

|

Automated features and programmable settings streamline the drying process, reducing the need for manual intervention. This lowers labor costs and improves overall operational efficiency. |

|

8. Space-Saving Design |

|

Microwave drying equipment often has a compact and space-saving design, making it suitable for both large-scale production facilities and smaller processing operations. Its modular construction allows for easy integration into existing production lines. |

|

9. Minimal Environmental Impact |

|

Compared to traditional drying methods that may rely on fossil fuels or produce harmful emissions, microwave drying equipment offers a cleaner and more environmentally friendly alternative. It reduces greenhouse gas emissions and minimizes environmental footprint. |

|

10. Enhanced Safety |

|

Microwave drying equipment is equipped with safety features to prevent accidents and ensure operator protection. These include automated shut-off mechanisms, temperature sensors, and protective enclosures, maintaining a safe working environment. |

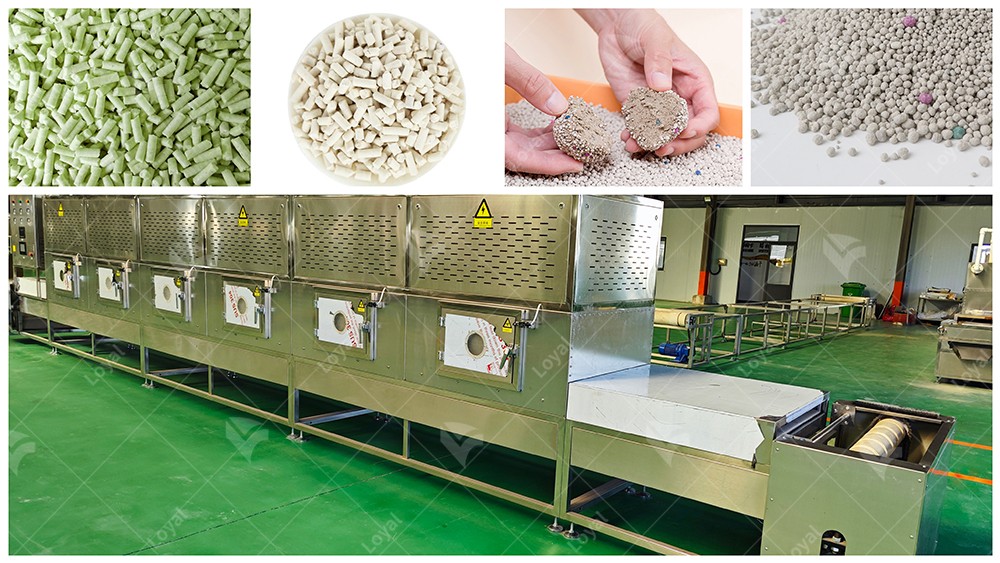

Types of Microwave Drying Equipment

Microwave drying equipment has evolved significantly to meet the diverse needs of various industries, offering efficient solutions for drying a wide range of products. In 2024, several types of microwave drying equipment dominate the market, each with its unique features and applications.

1. Batch Microwave Drying Equipment:

Batch microwave drying equipment is designed to process a limited quantity of material at a time. It typically consists of a chamber or cavity where the product is placed for drying, along with microwave generators and controls. This type of equipment is commonly used for small-scale production or research and development purposes, offering flexibility and ease of operation. Batch systems are ideal for drying high-value products or for applications requiring frequent changes in product types or processing parameters.

2. Continuous Microwave Drying Systems:

Continuous microwave drying systems are designed for large-scale production environments where efficiency and throughput are paramount. These systems feature a conveyor belt or other continuous feed mechanism that transports the product through a series of microwave chambers for drying. Continuous systems offer high throughput rates and consistent drying performance, making them ideal for mass production of commodities such as grains, nuts, and seeds. They are also well-suited for applications requiring precise control over drying parameters and uniform product quality.

3. Hybrid Microwave Drying Equipment:

Hybrid microwave drying equipment combines microwave technology with other drying methods, such as hot air convection or infrared heating. This hybrid approach leverages the advantages of both technologies to achieve faster drying rates, improved energy efficiency, and superior product quality. Hybrid systems are particularly effective for drying heat-sensitive or delicate products that require gentle treatment. They offer flexibility in adjusting drying parameters to accommodate different product characteristics and processing requirements.

4. Vacuum Microwave Drying Equipment:

Vacuum microwave drying equipment operates under reduced pressure conditions, allowing for lower drying temperatures and faster moisture removal. This type of equipment is especially suitable for drying heat-sensitive materials that may degrade or undergo undesirable chemical reactions at high temperatures. Vacuum microwave drying preserves the nutritional value, color, and flavor of the products, making it ideal for applications such as drying fruits, vegetables, and herbs. Additionally, vacuum conditions help to prevent oxidation and preserve product freshness during the drying process.

5. Laboratory-Scale Microwave Drying Systems:

Laboratory-scale microwave drying systems are compact and versatile units designed for research, development, and testing purposes. These systems allow researchers and scientists to evaluate the feasibility of microwave drying for specific products, optimize processing parameters, and assess product quality. Laboratory-scale equipment typically offers precise control over drying conditions, allowing for detailed experimentation and analysis. These systems play a crucial role in advancing microwave drying technology and expanding its applications across various industries.

Key components of microwave drying equipment

|

Component |

Description |

|

Microwave Generator |

The microwave generator is the core component of the equipment, responsible for generating and emitting microwave energy. It converts electrical energy into microwave radiation, typically at frequencies of 2450 MHz for industrial applications. High-power magnetrons or solid-state generators are commonly used for this purpose. |

|

Waveguide |

The waveguide is a hollow metallic tube or channel that guides the microwave energy from the generator to the processing chamber. It ensures the efficient transmission of microwaves while preventing leakage and minimizing energy loss. Proper design and construction of the waveguide are essential to maintain uniform heating throughout the chamber. |

|

Processing Chamber |

The processing chamber is where the actual drying process takes place. It is typically constructed of stainless steel or other non-reactive materials to withstand the high temperatures and moisture levels encountered during operation. The chamber may be equipped with rotating trays, conveyor belts, or other mechanisms to facilitate the even distribution of the product and exposure to microwave energy. |

|

Control System |

The control system consists of electronic components and software that regulate and monitor various parameters of the drying process. This includes controlling the power output of the microwave generator, adjusting the processing time and temperature, and ensuring safety interlocks are in place. Advanced control systems may incorporate sensors, PLCs (Programmable Logic Controllers), and HMI (Human-Machine Interface) for precise control and real-time monitoring of the equipment's operation. |

|

Ventilation System |

The ventilation system is responsible for removing excess moisture and hot air from the processing chamber during the drying process. It helps maintain optimal humidity levels inside the chamber, prevents condensation, and ensures efficient drying. The ventilation system may include fans, exhaust ducts, and filters to circulate air and remove moisture-laden air from the chamber. Proper ventilation design is critical to prevent overheating and ensure uniform drying of the product. |

Comparison and advantages of microwave technology and traditional drying methods

|

Aspect |

Microwave Drying Equipment |

Traditional Drying Methods |

|

Heating Mechanism |

Utilizes electromagnetic waves to directly heat the product, resulting in rapid and uniform heating. |

Relies on convection, conduction, or radiation to transfer heat to the product, which can lead to uneven heating and longer drying times. |

|

Drying Time |

Offers significantly shorter drying times compared to traditional methods, leading to higher throughput and productivity. |

Often requires longer drying times due to slower heat transfer rates, resulting in lower throughput and productivity. |

|

Product Quality |

Preserves product quality by minimizing heat exposure, resulting in better retention of nutrients, flavor, and color. |

May compromise product quality due to prolonged exposure to high temperatures, leading to nutrient degradation and flavor loss. |

|

Energy Efficiency |

Generally more energy-efficient due to the direct heating mechanism, resulting in lower energy consumption and operating costs. |

Can be less energy-efficient, especially in systems where heat is generated externally and transferred to the product indirectly. |

|

Space and Footprint |

Typically requires less floor space and has a smaller footprint, making it suitable for compact production environments. |

May require larger drying chambers or equipment setups, resulting in a larger footprint and higher space requirements. |

|

Flexibility and Control |

Offers precise control over drying parameters such as temperature, humidity, and power levels, allowing for customizable drying processes. |

May offer limited control over drying parameters, depending on the specific drying method used, leading to less flexibility in process optimization. |

|

Environmental Impact |

Generally has a lower environmental impact due to shorter drying times and reduced energy consumption, leading to lower greenhouse gas emissions. |

May have a higher environmental impact, especially in systems that rely on fossil fuels or non-renewable energy sources for heat generation. |

Technical Parameters

|

Technical Parameters Of Continuous Microwave Dryer Industrial Microwave Drying Machine |

|||||

|

Model |

Size LWH(Can be customized according |

Output |

Dewaterability |

Sterilization |

Baking and Roasting capacity |

|

LY-10KW |

5000mm825mm1750mm |

≥10KW |

10KG/Hour |

100KG/Hour |

30-50KG/Hour |

|

LY-20KW |

8000mm825mm1750mm |

≥20KW |

20KG/Hour |

200KG/Hour |

60-100KG/Hour |

|

LY-30KW |

8500mm1160mm1750mm |

≥30KW |

30KG/Hour |

300KG/Hour |

90-150 KG/Hour |

|

LY-40KW |

10000mm1160mm1750mm |

≥40KW |

40KG/Hour |

40KG/Hour |

120-200KG/Hour |

|

LY-50KW |

12500mm1160mm1750mm |

≥50KW |

50KG/Hour |

500KG/Hour |

150-250KG/Hour |

|

LY-60KW |

13500mm1450mm1750mm |

≥60KW |

60KG/Hour |

600KG/Hour |

180-300KG/Hour |

|

LY-70KW |

13500mm1500mm1750mm |

≥70KW |

70KG/Hour |

700KG/Hour |

210-350KG/Hour |

|

LY-80KW |

13500mm1650mm1750mm |

≥80KW |

80KG/Hour |

800KG/Hour |

240-400KG/Hour |

|

LY-100KW |

16800mm1650mm1750mm |

≥100KW |

100KG/Hour |

1000KG/Hour |

300-500KG/Hour |

|

LY-150KW |

22400mm1850mm1750mm |

≥150KW |

150KG/Hour |

1500KG/Hour |

450-750KG/Hour |

|

LY-200KW |

27000mm1850mm1750mm |

≥250KW |

250KG/Hour |

2500KG/Hour |

750-1250/Hour |

|

LY-300KW |

32000mm1850mm1750mm |

≥300KW |

300KG/Hour |

3000KG/Hour |

900-1500KG/Hour |

|

Power Supply |

380V±10% 50Hz±1% Three-Phase Five-Wire |

||||

|

Microwave Output Frequency |

2450±50Mhz |

||||

|

Microwave Input Apparent Power |

≤168Kva |

||||

|

Microwave Output Power |

≥120Kw |

||||

|

Microwave Power Adjustment Range |

0-30Kw(Adjustable) |

||||

|

Ambient Temperature |

-5-40°C |

||||

|

Relative Humidity |

≤80%, Surrounding Environment:No Corrosive Gas, Conductive Dust And Explosive Gas |

||||

|

Transmission Speed |

0-10m/Min(Adjustable) |

||||

Application of Microwave Drying Equipment

Microwave drying equipment has found widespread application across various industries due to its efficiency, speed, and ability to preserve product quality. In 2024, the utilization of microwave drying equipment continues to expand, revolutionizing the way certain products are processed and manufactured.

Food Industry:

In the food industry, microwave drying equipment plays a crucial role in preserving the quality and flavor of perishable food products. It is extensively used for drying fruits, vegetables, herbs, and spices, as well as for processing meat and seafood. The rapid and uniform heating provided by microwave technology helps retain nutrients, color, and texture, resulting in superior-quality dried products. Additionally, microwave drying equipment enables manufacturers to meet stringent food safety standards by effectively controlling moisture levels and minimizing the risk of microbial contamination.

Pharmaceuticals and Nutraceuticals:

Microwave drying equipment is also widely employed in the pharmaceutical and nutraceutical industries for the drying and sterilization of medicinal herbs, botanical extracts, and dietary supplements. By utilizing precise temperature and moisture control, microwave drying ensures the preservation of active ingredients and bioactive compounds, thereby enhancing the efficacy and shelf life of pharmaceutical and nutraceutical products. Furthermore, the rapid drying process reduces the exposure of sensitive materials to heat, minimizing the risk of degradation and ensuring product integrity.

Chemical and Materials Processing:

In chemical and materials processing applications, microwave drying equipment offers advantages such as rapid drying times, energy efficiency, and precise temperature control. It is commonly used for drying polymers, ceramics, and composite materials, as well as for the removal of solvents and moisture from chemical compounds. The uniform heating provided by microwave technology facilitates faster drying rates and reduces the risk of thermal degradation, making it suitable for delicate or heat-sensitive materials.

Textile and Paper Industry:

In the textile and paper industry, microwave drying equipment is utilized for the drying and curing of coatings, inks, and adhesives applied to fabrics and paper products. The controlled application of microwave energy allows for efficient moisture removal without causing damage to the substrate material. Moreover, microwave drying offers advantages such as reduced drying times, improved product quality, and lower energy consumption compared to conventional drying methods, making it a preferred choice for certain applications within the textile and paper manufacturing processes.

Post-maintenance of Microwave Drying Equipment

After the initial installation and commissioning of microwave drying equipment, post-maintenance plays a crucial role in ensuring optimal performance, longevity, and safety. Here's a comprehensive guide on the post-maintenance procedures for microwave drying equipment in 2024.

1. Regular Inspection and Cleaning:

Following the manufacturer's guidelines, conduct regular inspections of all components of the microwave drying equipment. Check for any signs of wear and tear, loose connections, or accumulation of debris. Clean the interior and exterior surfaces of the equipment to prevent contamination and maintain hygiene standards.

2. Calibration and Adjustment:

Periodically calibrate the microwave power output and temperature control systems to ensure accurate and consistent drying performance. Adjust any settings or parameters as necessary to optimize efficiency and product quality. Calibration should be performed by trained personnel using calibrated instruments for precise measurements.

3. Lubrication and Maintenance of Moving Parts:

Ensure that all moving parts, such as conveyor belts, bearings, and motors, are properly lubricated and maintained according to the manufacturer's recommendations. Lubrication prevents friction and wear, prolonging the lifespan of the equipment and reducing the risk of breakdowns or malfunctions.

4. Safety Checks and Testing:

Regularly conduct safety checks and functional testing of safety features, emergency stop mechanisms, and interlock systems. Verify that all safety devices are in proper working condition and comply with regulatory standards. Perform electrical testing and insulation resistance checks to identify any potential hazards or faults.

5. Software Updates and Upgrades:

Keep abreast of software updates and upgrades provided by the equipment manufacturer. Install the latest firmware updates to benefit from performance improvements, bug fixes, and enhanced features. Ensure that software updates are performed by qualified personnel to minimize the risk of errors or compatibility issues.

6. Training and Skill Development:

Invest in ongoing training and skill development for maintenance personnel responsible for servicing microwave drying equipment. Provide comprehensive training on equipment operation, troubleshooting, and safety procedures. Encourage continuous learning and certification programs to stay updated on emerging technologies and best practices.

7. Documentation and Record-keeping:

Maintain detailed records of all maintenance activities, including inspections, repairs, and replacements. Keep a log of equipment performance metrics, such as drying times, energy consumption, and product quality indicators. Documentation facilitates traceability, trend analysis, and proactive maintenance planning.

References

The following are five authoritative foreign literature websites in the field of industrial microwaves:

1. IEEE Xplore Digital Library

Website: [https://ieeexplore.ieee.org/]

2.ScienceDirect

Website: [https://www.sciencedirect.com/]

3. SpringerLink

Website: [https://link.springer.com/]

4. Wiley Online Library

Website: [https://onlinelibrary.wiley.com/]

5. PubMed

Website: [https://pubmed.ncbi.nlm.nih.gov/]

Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines