- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Company News> Everything you need to know about cookie making machine In 2024

Everything you need to know about cookie making machine In 2024

2024-04-26 15:27:38Introduction

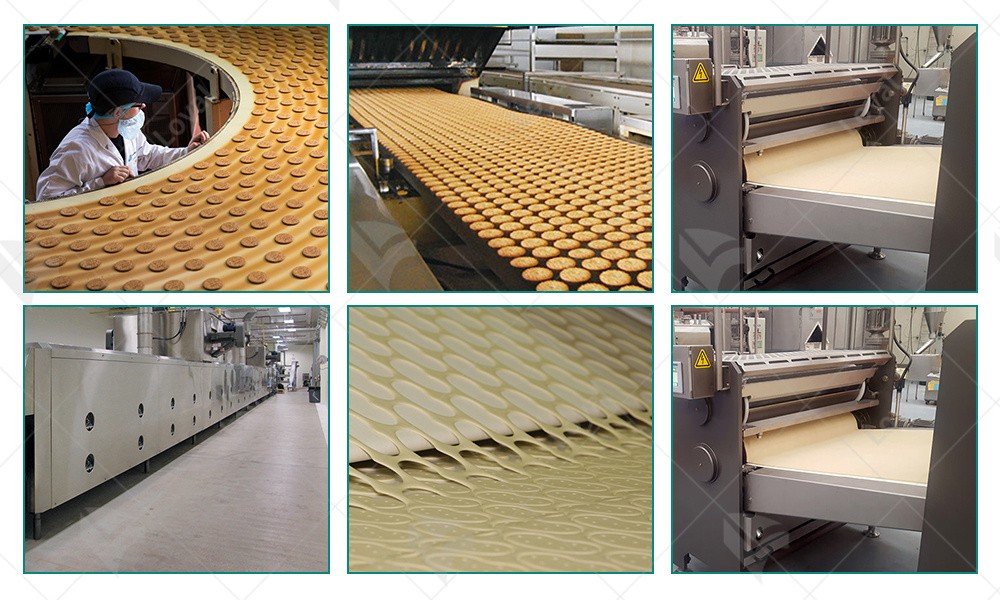

In 2024, the cookie making machine is not just a piece of equipment in the bakery—it is the heartbeat of the cookie production process. As the demand for a wide variety of cookies grows, the role of these machines becomes increasingly significant. They are the driving force behind the consistent quality, mass production, and innovative designs that cookie lovers have come to expect.

The cookie making machine is the embodiment of industrial innovation, combining artistry with automation to deliver a product that is both delicious and reliable. In this guide, we will explore the various aspects of these machines, from their key components to the latest technological advancements, and their role in shaping the future of the cookie industry.

Key Components and Features of Modern Cookie Making Machines

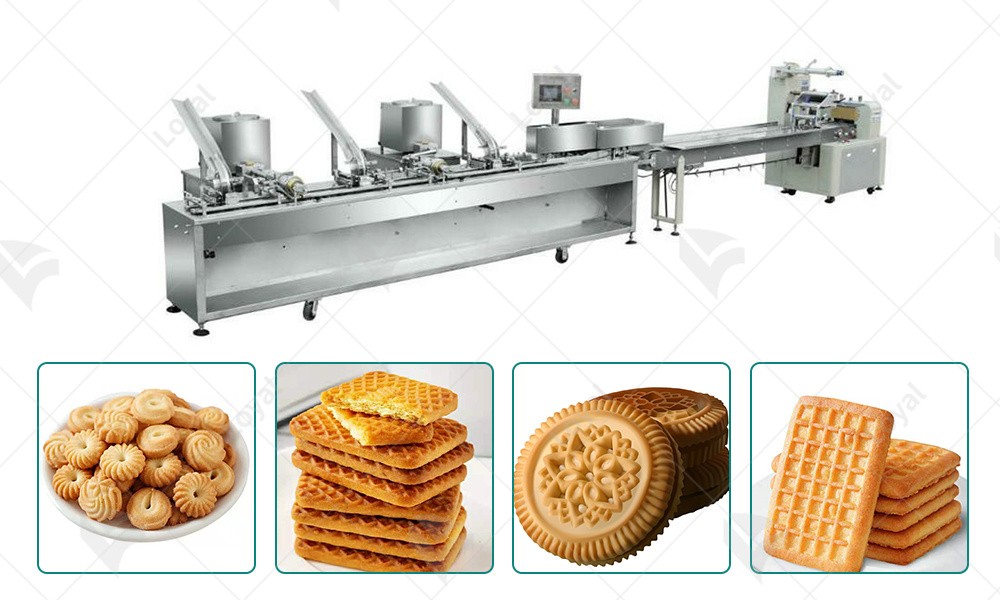

At the core of every modern cookie making machine is a suite of components and features that work in harmony to transform raw ingredients into finished products with precision and speed. Understanding these integral parts provides insight into the sophisticated nature of industrial cookie production.

1. Dough Preparation System: The process begins with the preparation of dough, which is meticulously mixed to achieve the perfect consistency. The system ensures uniform distribution of ingredients, which is crucial for the texture and taste of the cookies.

2. Dough Divider and Rounder: These components accurately divide the dough into equal portions and round them into balls. This stage is vital for achieving uniformity in size and shape, which is essential for even baking and consistent presentation.

3. Cookie Stamping Mechanism: The machine impresses a pattern onto the dough balls, giving cookies their distinctive shapes and designs. This mechanism can be customized to create a wide variety of cookie styles.

4. Baking Oven: The heart of the cookie making machine, the baking oven uses precise temperature control and even heat distribution to ensure that cookies bake perfectly. Modern ovens may incorporate convection technology for faster and more uniform baking.

5. Cooling Conveyor: Once baked, cookies are transferred to a cooling conveyor that allows them to cool uniformly before packaging. This stage is critical for maintaining the texture and quality of the cookies.

6. Automatic Packaging System: The final stage in the process is the automatic packaging of the cooled cookies. This system can be tailored to various packaging styles, from individual wrapping to bulk packaging, ensuring that cookies are protected and presented appealingly for retail.

7. Control Panel and Interface: The machine's control panel is the operator's interface with the system. It allows for the setting of parameters, monitoring of the process, and troubleshooting, with intuitive design for ease of use.

8. Sanitary Design: Modern cookie making machines are designed with hygiene in mind. Components are easy to clean and made from materials that resist corrosion and the buildup of bacteria, meeting the stringent food safety standards.

9. Energy-Efficiency Features: To reduce operational costs and environmental impact, these machines incorporate energy-saving features such as variable speed drives, energy recovery systems, and optimized heating elements.

10. Modularity and Scalability: The design of contemporary cookie making machines allows for modular components, making it easy to add or remove parts to suit different production needs or to scale up production capacity.

The integration of these components and features into a single, cohesive system is what makes the modern cookie making machine an indispensable asset in the cookie manufacturing industry. As technology continues to evolve, these machines will only become more sophisticated, offering greater efficiency, flexibility, and control over the cookie-making process.

Technological Innovations in 2024 Cookie Making Machines

The year 2024 marks a significant milestone in the evolution of the cookie making machine, with a plethora of technological innovations that are redefining the capabilities and efficiency of these industrial workhorses.

1. Smart Sensors and IoT Integration: The Internet of Things (IoT) is no longer a futuristic concept; it's a reality in modern cookie making. Machines are now equipped with smart sensors that collect real-time data on the production process, allowing for minute adjustments and optimizations that were not possible before.

2. Artificial Intelligence (AI): AI is playing an increasingly prominent role in the operation of cookie making machines. Machine learning algorithms can analyze the data collected by IoT devices to predict and correct potential issues before they become problems, leading to fewer production halts and higher consistency in product quality.

3. 3D Printing for Mold Design: While traditional methods for creating cookie molds have served well for decades, 3D printing technology is offering new possibilities for intricate and unique cookie designs. This allows manufacturers to quickly prototype and implement new cookie shapes, responding more rapidly to market trends and consumer demands.

4. Energy-Efficient Drives: Variable frequency drives (VFDs) and other energy-efficient technologies are now standard in many cookie making machines. These drives allow for precise control over the speed of various machine components, leading to energy savings and improved product quality.

5. Robotic Automation: Robotics have advanced to the point where they can perform delicate tasks such as handling and placing dough with a gentle touch that mimics human dexterity. This level of automation increases production speed while maintaining the quality of the cookies.

6. Vision Systems for Quality Control: High-resolution cameras and vision systems are being used to inspect cookies as they move through the production line. These systems can detect even minor imperfections in size, shape, or appearance, ensuring that only the best products reach the consumer.

7. Sustainable Technologies: In line with global sustainability goals, cookie making machines are incorporating technologies that reduce water and energy consumption. For example, heat recovery systems capture and reuse waste heat, and water-efficient cleaning systems minimize water use.

8. Augmented Reality (AR) for Maintenance: AR technology is being used to assist maintenance personnel in diagnosing and fixing issues with cookie making machines. By overlaying digital instructions and schematics onto the physical machine, technicians can perform maintenance tasks more quickly and accurately.

9. Customization Software: Advances in software allow for greater customization of the cookie-making process. Manufacturers can easily change recipes, shapes, and sizes directly from a user interface, without the need for significant mechanical adjustments.

10. Cloud Connectivity: With cloud connectivity, data from cookie making machines can be accessed and analyzed from anywhere. This allows for remote monitoring of the production process, predictive maintenance scheduling, and centralized management of multiple production lines.

These technological innovations are transforming the cookie making machine into a highly intelligent, flexible, and efficient tool for cookie production. As technology continues to advance, the capabilities of these machines will only expand, offering manufacturers unprecedented control over the cookie-making process and the ability to meet the ever-changing demands of the market.

Efficiency and Productivity Benefits of Cookie Making Machines

The integration of advanced technology into cookie making machines has led to significant gains in efficiency and productivity for the cookie manufacturing industry.

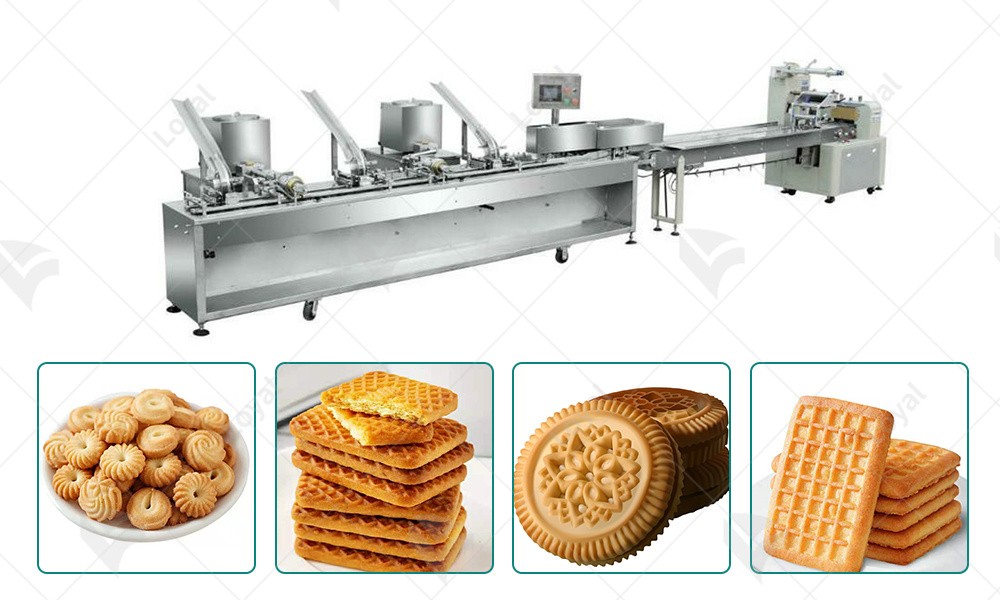

1. Increased Output: Automated cookie making machines can produce a high volume of cookies in a short amount of time, meeting the demands of large-scale production without compromising on quality.

2. Consistency in Quality: One of the main advantages of using these machines is the uniformity they offer. Every cookie produced is identical in size, shape, and weight, leading to a consistent eating experience for consumers.

3. Reduced Labor Costs: By automating the cookie-making process, the need for manual labor is greatly reduced. This not only lowers labor costs but also minimizes the risk of human error during production.

4. Energy Efficiency: Modern machines are designed to be energy efficient, using less power to perform the same tasks. This leads to lower operational costs and a reduced environmental impact.

5. Quick Changeovers: Many cookie making machines are built to be versatile, allowing for quick changeovers between different cookie types and recipes. This flexibility enables manufacturers to cater to diverse market demands and seasonal trends.

6. Extended Product Shelf Life: Precise control over the baking process ensures that cookies are baked to perfection every time, which can extend their shelf life and reduce waste due to spoilage.

7. Scalability: As business needs grow, these machines can be scaled up to increase production capacity without a proportional increase in labor or energy costs.

In essence, cookie making machines are a testament to the power of automation and technology in driving industrial efficiency and productivity. They enable manufacturers to produce high-quality cookies at scale, with minimal resource input, positioning the industry for sustainable growth and success.

Sustainability in Cookie Making Machine Operations

Sustainability has become a key focus for the food industry, and cookie making machines are at the forefront of this shift towards eco-friendly practices.

1. Energy-Efficient Design: Modern machines are built with energy efficiency in mind, using less power to produce the same volume of cookies. This not only reduces operational costs but also aligns with the industry's goal of minimizing its carbon footprint.

2. Water Conservation: Sustainable cookie making machines often incorporate features that conserve water, such as efficient cleaning systems and heat recovery technologies that reduce the need for hot water.

3. Reduced Waste: The precision of automated machines means less dough is wasted in the production process. This not only saves ingredients but also decreases the amount of food waste generated.

4. Recyclable Packaging: Many manufacturers are opting for recyclable or biodegradable packaging materials for their cookies, further reducing the environmental impact of their products.

5. Longevity and Durability: High-quality cookie making machines are designed to last, reducing the need for frequent replacements and the associated waste. Durable machines also minimize the need for repairs, further conserving resources.

6. Local Sourcing: Where possible, manufacturers are sourcing ingredients locally to reduce the carbon footprint associated with transportation. This also supports local economies and promotes sustainable farming practices.

By embracing sustainability, the operators of cookie making machines are not only contributing to a healthier planet but also meeting the growing consumer demand for green products. As sustainability continues to be a priority for consumers and regulators alike, it's clear that eco-friendly practices are not just a trend but a necessary evolution for the industry.

Maintenance and Operational Best Practices for Cookie Making Machines

Proper maintenance is crucial for the longevity and optimal performance of cookie making machines. Here are some key best practices to ensure these machines run smoothly and efficiently:

1. Regular Inspections: Conduct routine inspections of the machine to identify any potential issues before they become major problems. Check for signs of wear, loose parts, or any unusual operation.

2. Cleanliness: Keep the machine clean after each use. Food residue can affect the performance of the machine and lead to hygiene issues. A clean machine also helps to prevent ingredient cross-contamination.

3. Lubrication: Regularly lubricate moving parts as specified in the machine's manual. Proper lubrication reduces friction, which can extend the life of the machine and improve its efficiency.

4. Training: Ensure that all operators are well-trained in the use and maintenance of the cookie making machine. This includes understanding how to load ingredients, set machine parameters, and perform basic troubleshooting.

5. Preventive Maintenance: Establish a preventive maintenance schedule based on the manufacturer's recommendations. This may include tasks such as replacing worn parts, checking electrical connections, and calibrating the machine.

6. Emergency Stops and Safety Features: Familiarize yourself with the machine's emergency stop procedures and safety features. Regularly test these features to ensure they are functioning correctly.

7. Service Contracts: Consider a service contract with the manufacturer or a qualified technician. Regular professional maintenance can help to identify and resolve issues before they lead to costly downtime.

8. Spare Parts: Keep a stock of common wear-and-tear parts on hand. Having spare parts readily available can minimize the time the machine is out of operation due to maintenance or repairs.

9. Documentation: Keep a record of all maintenance and repairs performed on the machine. This documentation can help to identify patterns, anticipate future issues, and provide a history for the machine.

By following these best practices, you can maximize the efficiency and lifespan of your cookie making machine, ensuring a consistent supply of high-quality cookies and minimizing disruption to your production schedule.

Regulatory Compliance and Safety Standards for Cookie Making Machines

Ensuring that cookie making machines meet regulatory compliance and safety standards is critical for the cookie production industry. Here's a closer look at the importance of these standards and how they are being addressed.

1. Compliance with Food Safety Standards: The primary regulatory concern for any food production machinery, including cookie making machines, is compliance with food safety standards. These standards, often mandated by agencies like the FDA or the EU's EFSA, ensure that the machinery does not contaminate the product and that it maintains high hygiene levels. Machines are often required to have features that facilitate easy cleaning and prevent the buildup of food residue, which can harbor harmful bacteria.

2. Machine Safety Regulations: Beyond food safety, there are also strict machine safety regulations that must be followed. These involve the design of the machinery to prevent accidents, such as emergency stop buttons, safety guards to prevent contact with moving parts, and interlock systems that stop the machine if a door is opened during operation. Regular safety checks and staff training on how to use the machinery safely are also key components of compliance.

3. Environmental and Energy Efficiency Standards: Modern regulations also focus on the environmental impact of industrial operations. Cookie making machines are now expected to be energy efficient, reducing the carbon footprint of the production process. This might involve using energy-saving technologies, optimizing the baking process to reduce waste, and employing sustainable practices in the overall operation of the machinery.

By adhering to these regulatory standards, manufacturers not only avoid legal penalties but also contribute to a safer, more sustainable food production process. Compliance is a sign of a manufacturer's commitment to quality, safety, and environmental responsibility, which can also enhance their reputation and consumer trust.

Future Trends and Predictions for Cookie Making Machine Technology

As we look ahead, the future of cookie making machine technology promises to be as delicious as the cookies they produce, with several emerging trends shaping the industry.

1. Increased Automation: The push for automation will continue, with machines taking on more complex tasks and offering greater flexibility in production. This will allow for quicker adaptation to market changes and increased customization of products.

2. Sustainability Focus: There will be an even stronger emphasis on sustainability, with machines designed to use fewer resources, produce less waste, and operate more efficiently. This includes the use of renewable energy sources and the incorporation of recycled materials in machine construction.

3. Smart Machine Integration: The use of smart technology, including IoT devices and AI, will become more prevalent. These technologies will enable better monitoring of the production process, predictive maintenance, and improved quality control.

4. Health and Wellness: As consumer preferences shift towards healthier options, cookie making machines will need to adapt to produce cookies with healthier ingredients, such as whole grains, less sugar, and plant-based alternatives.

5. Customization and Personalization: The ability to customize cookies, from shape and size to flavor and nutritional content, will become more important. Machines will need to be versatile enough to accommodate a wide range of recipes and specifications.

6. Extended Product Lines: We can expect to see cookie making machines that are capable of producing a broader range of products, from traditional cookies to biscuits, crackers, and other baked goods.

7. Global Compliance: With the expansion of markets, machines will need to meet a wider array of international standards and regulations, ensuring they can be used globally without compromising on safety or quality.

The future of cookie making machines is bright, with technology driving innovation and efficiency. As consumer demands evolve and the world becomes more interconnected, these machines will play a critical role in meeting the challenges of the future, all while ensuring we can continue to enjoy our favorite cookies.

Conclusion

In conclusion, the cookie making machine is a testament to the innovation and progress within the food manufacturing industry. These machines are not just tools for production; they are the driving force behind the consistent quality, mass production, and creative variety that consumers have come to expect from their favorite cookies. As technology continues to evolve, the capabilities of these machines will only expand, offering manufacturers greater control, efficiency, and the ability to meet the dynamic demands of the market.

The future of the cookie industry, backed by the advancement of cookie making machines, is bright and promising. With a focus on sustainability, customization, and smart technology integration, these machines are set to play a pivotal role in shaping the future of cookie production. As we embrace these changes, the joy of cookies can be experienced by consumers worldwide, made possible by the relentless pursuit of innovation in the realm of industrial food machinery.

Reference

1. Food Processing:

Website: [Food Processing](https://www.foodprocessing.com/)

2. Food Engineering:

Website: [Food Engineering](https://www.foodengineeringmag.com/)

3. Process Industry Forum:

Website: [Process Industry Forum](https://www.processindustryforum.com/)

4. Food Manufacture:

Website: [Food Manufacture](https://www.foodmanufacture.co.uk/)

Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines