- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Company News> The Ultimate Japanese Panko Bread Crumbs Making Machine Guide to 2024

The Ultimate Japanese Panko Bread Crumbs Making Machine Guide to 2024

2024-06-05 17:47:30Introduction to Panko Bread Crumbs

Panko bread crumbs, a staple in Japanese cuisine, are known for their light, airy texture and superior crunch. Unlike traditional bread crumbs, panko is made from crustless bread, which is coarsely ground into large, flaky crumbs. This unique texture allows panko to absorb less oil, making it a healthier option for frying foods, resulting in a lighter, crunchier coating.

The popularity of panko has grown beyond Japanese cuisine, becoming a favorite ingredient in various culinary traditions worldwide. Its versatility makes it an ideal coating for fried foods, a crunchy topping for casseroles, and even a binder in meatballs and burgers. The distinctive texture of panko provides a superior mouthfeel, enhancing the overall dining experience.

To meet the increasing demand for panko bread crumbs, the food processing industry relies on advanced machinery designed specifically for panko production. The Japanese panko bread crumbs making machine is at the forefront of this technology, offering high efficiency, consistency, and quality in panko production. These machines are engineered to replicate traditional panko production methods while incorporating modern automation and control technologies to ensure scalability and precision.

Understanding the Panko Production Process

The production of panko bread crumbs involves several critical steps, each contributing to the final product's unique texture and quality. The process begins with the preparation of bread dough, where precise measurements of ingredients are mixed and kneaded to achieve the ideal consistency. This dough is then shaped and baked, typically using a specialized electric oven that ensures even cooking without forming a crust.

Once baked, the bread is left to cool before it is processed further. The cooling phase is essential as it allows the bread to firm up, making it easier to cut and grind into the desired panko crumb size. The Japanese panko bread crumbs making machine plays a crucial role in this stage. Using advanced cutting and grinding mechanisms, the machine slices the bread into coarse, airy flakes. This process is carefully controlled to maintain the characteristic large, irregular panko crumb shape.

After grinding, the panko crumbs are typically dried to reduce moisture content, ensuring a longer shelf life and maintaining the desired texture. The drying process is conducted using low temperatures to preserve the bread crumbs' delicate structure and flavor. Finally, the dried panko is sifted to remove any fine particles, resulting in uniform, high-quality bread crumbs ready for packaging and distribution.

The entire panko production process is optimized for efficiency and consistency through the use of automated systems. These systems monitor and adjust parameters such as temperature, humidity, and cutting speed, ensuring each batch of panko meets stringent quality standards. By leveraging the capabilities of a Japanese panko bread crumbs making machine, manufacturers can produce large volumes of premium panko bread crumbs, catering to the global demand for this versatile ingredient.

Essential Components of a Panko Making Machine

|

Component |

Description |

Importance |

| Mixing Chamber | Where ingredients are combined and mixed to form dough. | Ensures consistent dough quality and texture. |

| Kneading Mechanism | Mechanically kneads the dough to develop gluten structure. | Essential for achieving the right texture in bread. |

| Extruder | Shapes the dough into specific forms before baking. | Creates uniform shapes for even baking. |

| Conveyor Belt | Transports dough through various stages of production. | Facilitates continuous production flow. |

| Baking Oven | Bakes the dough to create bread before it is turned into crumbs. | Provides precise temperature control for optimal baking. |

| Cooling System | Cools the baked bread to the appropriate temperature for further processing. | Prevents condensation and maintains product quality. |

| Grinding Mill | Breaks down baked bread into crumbs of desired size. | Ensures uniform crumb size and texture. |

| Sifting Mechanism | Separates crumbs by size, removing any oversized or undersized particles. | Guarantees consistent product quality. |

| Drying System | Reduces moisture content in crumbs to extend shelf life. | Crucial for preventing mold and spoilage. |

| Control Panel | User interface for managing machine operations and settings. | Allows precise control over the production process. |

| Safety Guards | Protects operators from moving parts and potential hazards. | Ensures workplace safety. |

| Lubrication System | Automatically lubricates moving parts to reduce wear and tear. | Extends the lifespan of the machine. |

| Dust Collection System | Captures and removes dust generated during grinding and sifting. | Maintains a clean working environment. |

| Hopper | Feeds raw materials into the machine at the beginning of the production line. | Enables continuous and efficient feeding. |

| Packaging Unit | Packages finished panko crumbs into bags or boxes for distribution. | Streamlines the final stage of production. |

Advanced Mixing and Kneading Technologies

In the production of Japanese panko bread crumbs, the mixing and kneading stages are critical for achieving the desired dough consistency and texture. Modern japanese panko bread crumbs making machines incorporate advanced technologies to optimize these processes, ensuring high-quality end products.

One significant advancement is the use of spiral mixers. These mixers are designed to handle large volumes of dough, providing thorough and consistent mixing. The spiral motion allows for even incorporation of ingredients, reducing the risk of uneven dough development. This results in a homogeneous mixture that is crucial for producing uniform bread crumbs.

Another innovative technology is the dual-arm kneader. This type of kneader simulates traditional hand-kneading techniques, which are known to produce superior dough texture. The dual arms work simultaneously to stretch and fold the dough, enhancing gluten development. This is essential for creating the airy, flaky texture characteristic of high-quality panko crumbs.

Additionally, many modern panko making machines feature automated ingredient dispensers. These dispensers accurately measure and add ingredients at the appropriate times during the mixing process. This automation ensures consistency between batches, minimizing human error and enhancing overall product quality.

Finally, the integration of temperature-controlled mixing bowls is a notable advancement. Maintaining the dough at an optimal temperature during mixing and kneading is crucial for proper yeast activity and gluten formation. Temperature-controlled bowls help maintain this optimal environment, leading to better dough handling and consistency.

Innovative Baking and Drying Techniques

|

Technique |

Description |

Advantages |

| Convection Baking | Utilizes fans to circulate hot air evenly around the product. | Ensures uniform baking, reduces baking time, and improves texture consistency. |

| Infrared Baking | Uses infrared radiation to directly heat the surface of the bread. | Provides quick and even heating, enhancing crust formation and reducing energy consumption. |

| Vacuum Drying | Removes moisture under reduced pressure to preserve texture and flavor. | Retains natural color and taste, reduces drying time, and minimizes nutrient loss. |

| Flash Drying | Employs high-temperature air to rapidly dry bread crumbs. | Extremely fast drying process, reduces processing time, and increases production efficiency. |

| Hot Air Circulation Drying | Involves circulating hot air to remove moisture from the bread crumbs. | Consistent drying, energy-efficient, and maintains product quality. |

| Microwave Drying | Uses microwaves to heat and dry the bread crumbs from the inside out. | Fast drying, retains moisture balance, and ensures even drying without affecting texture. |

Grinding and Sieving Mechanisms

The grinding and sieving mechanisms in a Japanese panko bread crumbs making machine are critical for ensuring the desired texture and consistency of the final product. These mechanisms involve several key stages and technologies designed to produce high-quality panko bread crumbs.

High-Precision Grinding

High-precision grinding is essential for breaking down the baked bread into uniform crumbs. Modern panko making machines use advanced grinding technologies that include adjustable grinding plates and precision-engineered blades. These components work together to finely grind the bread without generating excessive heat, which can alter the taste and texture of the crumbs. The result is a consistent particle size that meets industry standards for panko bread crumbs.

Multi-Stage Sieving

Following the grinding process, multi-stage sieving is employed to sort the bread crumbs by size. This step ensures that only the appropriately sized particles are included in the final product. Advanced sieving systems utilize vibrating screens and air classifiers to efficiently separate the crumbs. The sieves are designed with various mesh sizes to filter out any larger or smaller particles that do not meet the specifications for panko crumbs. This precise sieving process is crucial for achieving the light and flaky texture characteristic of high-quality panko.

Airflow Separation

In addition to mechanical sieving, some panko bread crumb machines incorporate airflow separation technology. This method uses controlled air currents to further refine the crumb size and remove any remaining fine particles or dust. Airflow separation enhances the overall quality of the bread crumbs by ensuring they are free from impurities and have a uniform appearance. It also helps in maintaining the desired moisture content and prevents clumping during storage and packaging.

Quality Assurance

Throughout the grinding and sieving processes, continuous quality assurance measures are implemented to monitor and maintain product standards. This includes regular sampling and analysis of the bread crumbs to check for consistency in size, texture, and moisture levels. Advanced machines may also feature real-time monitoring systems that provide feedback to operators, allowing for immediate adjustments if any deviations are detected. By incorporating these quality control practices, manufacturers can ensure that their Japanese panko bread crumbs making machines produce a consistently superior product.

Key Features of Modern Panko Making Machines

|

Feature |

Description |

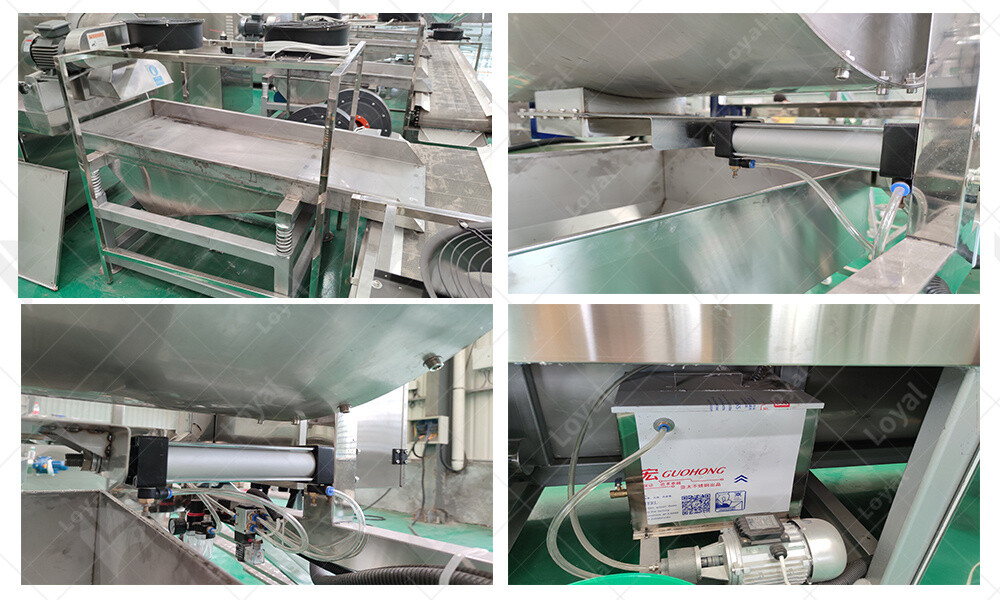

| Stainless Steel Construction | Durable construction using stainless steel materials ensures longevity and resistance to corrosion. |

| Variable Speed Control | Allows operators to adjust the speed of mixing, baking, and other processes to optimize production. |

| Automatic Ingredient Feeder | Precisely measures and adds ingredients to the mixture, ensuring consistency in the final product. |

| Programmable Touchscreen | Intuitive touchscreen interface for easy operation and programming of different production parameters. |

| Multi-Stage Baking System | Utilizes multiple stages of baking to achieve the perfect texture and color of panko bread crumbs. |

| High-Efficiency Heating | Incorporates energy-efficient heating elements to reduce energy consumption and production costs. |

| Integrated Cooling System | Rapidly cools down freshly baked panko crumbs to prevent overcooking and maintain product quality. |

| Easy-to-Clean Design | Features removable parts and smooth surfaces for quick and thorough cleaning between production runs. |

Leading Manufacturers of Panko Making Machines

|

Manufacturer |

Country |

Key Features |

| Mayosys Co., Ltd. | Japan | Offers a wide range of panko making machines with customizable features and options. |

| ANKO Food Machine Co. | Taiwan | Known for its versatile and efficient panko production lines suitable for various scales. |

| Shanghai Papa Machinery | China | Specializes in high-speed panko making machines with advanced automation capabilities. |

| LOYAL Food Machinery | China | Renowned for its robust and cost-effective panko making machines suitable for small to large-scale production. |

Maintenance and Cleaning Best Practices

Proper maintenance and cleaning of your Japanese panko bread crumbs making machine are essential to ensure optimal performance, product quality, and longevity of the equipment. By following best practices, you can minimize downtime, reduce the risk of contamination, and extend the lifespan of your machine.

Regular Inspection: Regularly inspecting your panko bread crumbs making machine is crucial. Look for signs of wear and tear, loose components, or any abnormal noises during operation. Addressing issues promptly can prevent further damage and ensure smooth operation.

Lubrication: Proper lubrication of moving parts is essential to reduce friction, prevent corrosion, and prolong the life of your machine. Follow manufacturer recommendations for the type and frequency of lubrication needed for each component.

Cleaning Procedures: After each production run, thoroughly clean all surfaces that come into contact with the panko bread crumbs. Use food-safe cleaning agents and sanitizers to eliminate any residue or contaminants. Pay special attention to areas prone to buildup, such as the mixing chamber and conveyor belts.

Regular Calibration: Regularly calibrate sensors and control systems to maintain accuracy and consistency in the production process. Ensure that temperature, moisture, and other critical parameters are calibrated according to specifications to produce high-quality panko bread crumbs consistently.

Preventive Maintenance Schedule: Develop a preventive maintenance schedule for your panko bread crumbs making machine. This schedule should include regular tasks such as lubrication, inspection, and cleaning, as well as periodic maintenance checks by qualified technicians.

Future Trends in Panko Bread Crumbs Making Technology

The landscape of panko bread crumbs making technology is continually evolving, driven by advancements in automation, sustainability, and efficiency. Looking ahead to 2024 and beyond, several trends are shaping the future of panko bread crumbs production.

Automation: Automation will continue to play a significant role in streamlining panko bread crumbs production processes. Advanced robotics, artificial intelligence, and machine learning technologies will enable greater efficiency, consistency, and throughput in panko making machines.

Sustainability: With increasing emphasis on sustainability, manufacturers are exploring eco-friendly alternatives in panko bread crumbs production. This includes energy-efficient equipment, recyclable packaging materials, and waste reduction initiatives to minimize the environmental impact of production processes.

Innovative Technologies: Emerging technologies such as 3D printing, nanotechnology, and smart sensors are poised to revolutionize the panko bread crumbs making industry. These innovations will enhance product quality, customization capabilities, and production flexibility, meeting the evolving demands of consumers and markets.

Reference

1.Baker Perkins - bakerperkins.com

2.GEA Group - gea.com

3.Heat and Control - heatandcontrol.com

4.Hosokawa Micron - hosokawamicron.com

5.Fritsch Group - fritsch-group.com

Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines