- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Company News> Everything you Need to Know About Breadcrumb Crushing Production

Everything you Need to Know About Breadcrumb Crushing Production

2024-06-19 17:49:52What is Breadcrumb Crushing Production?

Breadcrumb Crushing Production refers to the process of reducing baked bread into smaller particles or crumbs through specialized machinery in food production settings. This mechanical operation plays a crucial role in various industries, particularly in food processing and packaging. Breadcrumb Crushing Production machines are designed to efficiently break down loaves, buns, or other forms of baked bread into uniform crumbs of desired sizes, which are then used as ingredients or coatings in numerous culinary applications.

In industrial kitchens, Breadcrumb Crushing Production is essential for standardizing the texture and size of breadcrumbs, ensuring consistency in the final product. These crumbs can range from fine to coarse, depending on specific requirements dictated by the intended use in recipes or as coatings for fried or baked foods.

The equipment used for Breadcrumb Crushing Production is robust and often includes mechanisms to adjust the size of the crumbs produced, allowing manufacturers to meet diverse customer demands across the food industry. This process not only enhances efficiency but also maintains quality in food preparation by ensuring that crumbs are uniform and of high standard.

Importance of Breadcrumb Crushing Production

The process of Breadcrumb Crushing Production holds significant importance in food production, primarily due to its versatile applications and impact on final product quality. By converting baked bread into crumbs, manufacturers can efficiently manage surplus or imperfect loaves that might otherwise go to waste. This sustainable practice reduces food waste while maximizing the utility of raw materials.

Moreover, Breadcrumb Crushing Production plays a crucial role in ensuring consistency and quality in food products. Whether used as fillers in meat products, toppings on pasta dishes, or coatings for fried items like chicken tenders or fish fillets, the texture and size of breadcrumbs directly influence consumer satisfaction and product appeal. Uniform crumbs ensure even coverage and adherence during cooking, enhancing the overall sensory experience of the prepared dish.

In addition to culinary applications, Breadcrumb Crushing Production contributes to operational efficiency within food processing facilities. By mechanizing the crushing process, manufacturers can achieve higher throughput without compromising on quality standards. This efficiency not only supports large-scale production but also helps in maintaining competitive pricing in the market.

Furthermore, the versatility of breadcrumbs extends beyond culinary uses. They are also employed in non-food industries, such as pharmaceuticals and cosmetics, where finely ground crumbs serve as functional additives in various formulations.

In conclusion, Breadcrumb Crushing Production is a fundamental process in food machinery that enhances both operational efficiency and product quality across diverse applications. Its role in transforming surplus bread into valuable crumbs underscores its importance in sustainable food production practices while meeting the stringent demands of modern food processing standards.

Types of Machines Used

Breadcrumb crushing production relies on specialized machinery designed to efficiently process bread into crumbs of various sizes suitable for culinary applications. The key machines involved include:

|

Machine Type |

Description |

|

Crushers |

Crushers are primary machines used to crush bread into coarse crumbs. They utilize blunt surfaces or rotating blades to break down the bread effectively. |

|

Mills |

Mills are secondary machines that further refine bread crumbs into finer grades. They employ grinding mechanisms to achieve the desired texture. |

|

Sifters |

Sifters are used to separate larger crumbs from finer particles, ensuring uniformity in the final product. They employ screens or mesh to classify particle sizes. |

Each of these machines plays a crucial role in the breadcrumb production line, from initial crushing to final classification of particle sizes.

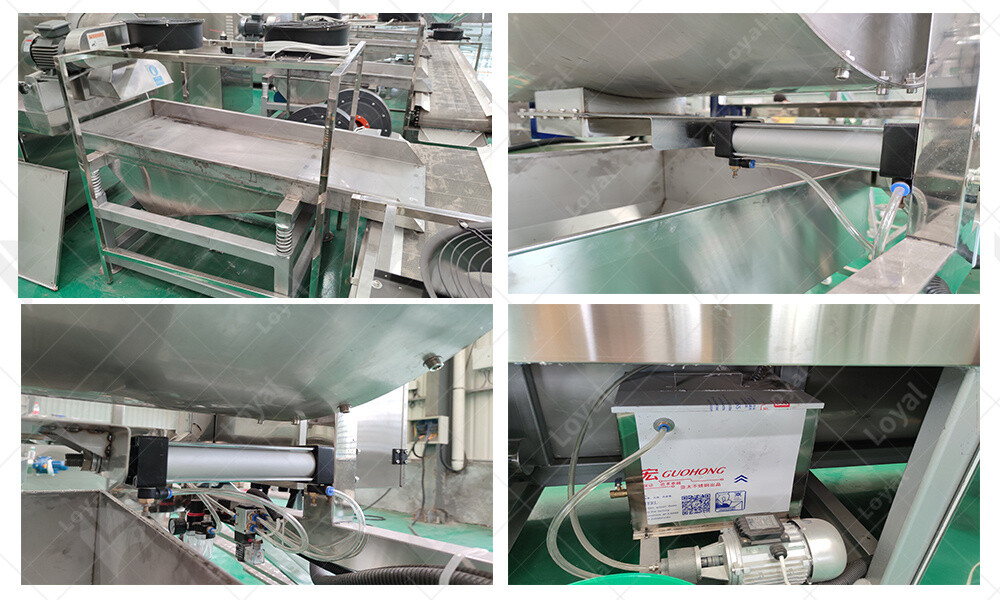

Key Components of Breadcrumb Crushing Machines

Breadcrumb crushing machines are intricate systems composed of several essential components, each contributing to the efficiency and quality of the breadcrumb production process. Here are the key components typically found in these machines:

|

Component |

Function |

|

Hopper |

The hopper is where bread is fed into the machine for processing. It ensures a continuous supply of bread for crushing. |

|

Crushing Mechanism |

This mechanism varies depending on the machine type but generally involves blades or rollers that crush the bread into crumbs. |

|

Conveyor Belt |

Conveyor belts transport bread through different stages of the crushing process, ensuring smooth and consistent operation. |

|

Grinding Chamber |

Found in mills, the grinding chamber houses the grinding mechanism responsible for refining bread into finer crumbs. |

|

Screens or Mesh |

These components are used in sifters to separate crumbs into various sizes, ensuring uniformity in the final product. |

|

Collection Bins |

Bins collect and store different grades of breadcrumbs, facilitating easy packaging and distribution. |

Each component is meticulously engineered to handle specific tasks within the breadcrumb crushing process, ensuring optimal performance and product quality.

Factors Influencing Production Efficiency

In the realm of industrial food machinery, Breadcrumb Crushing Production stands as a pivotal process that demands meticulous attention to efficiency. The throughput of breadcrumb production lines is profoundly influenced by several key factors, each playing a crucial role in determining overall operational effectiveness.

First and foremost, the design and calibration of the crushing machinery itself dictate much of the efficiency achieved in production. Modern advancements in rotor design and the integration of precision controls have significantly enhanced the throughput capabilities of breadcrumb crushers. The ability to finely adjust parameters such as rotor speed and feed rate ensures optimal utilization of raw materials while minimizing energy consumption—Breadcrumb Crushing Production hinges on these technological innovations.

Moreover, the consistency and quality of raw materials directly impact the efficiency of breadcrumb production lines. Variations in moisture content and particle size distribution can impede the flow through crushers, leading to bottlenecks and suboptimal performance. Therefore, stringent quality control measures at the intake stage are essential to maintain smooth operations and maximize output.

Furthermore, the automation level of the production line plays a pivotal role in enhancing efficiency. Automated systems not only streamline the crushing process but also enable real-time monitoring and adjustment of critical parameters. This level of control minimizes downtime due to manual interventions and ensures continuous operation at peak efficiency levels.

Lastly, maintenance practices and downtime management are integral to sustaining high production efficiency. Regular upkeep of crusher components, including blades and screens, prevents wear-induced performance degradation. Planned maintenance schedules and swift response to equipment malfunctions are paramount to minimizing production halts and optimizing overall equipment effectiveness (OEE).

Quality Control in Breadcrumb Crushing

Quality control in Breadcrumb Crushing Production is paramount to meeting stringent industry standards and ensuring customer satisfaction with the final product. This aspect of production involves comprehensive measures at every stage to uphold the integrity and consistency of crushed breadcrumbs.

Starting from the selection of raw materials, rigorous testing procedures are employed to verify essential quality parameters such as moisture content, particle size distribution, and purity. This initial screening ensures that only high-quality inputs enter the production process, thereby laying the foundation for superior end products.

During the crushing phase, precision instrumentation monitors key quality indicators, including particle uniformity and texture. Advanced sensors integrated into the crushing machinery enable real-time feedback on product characteristics, facilitating prompt adjustments to maintain desired quality standards.

Post-crushing, thorough inspection protocols are implemented to assess the final product's conformity to specifications. Automated sorting and grading systems categorize breadcrumbs based on size and texture, ensuring consistency across batches. This meticulous approach not only guarantees compliance with regulatory requirements but also enhances product reliability and market competitiveness.

In conclusion, Breadcrumb Crushing Production demands a holistic approach that harmonizes efficient throughput with uncompromising quality control measures. By optimizing machinery design, embracing automation, and adhering to rigorous quality standards, manufacturers can achieve peak operational efficiency while delivering breadcrumbs that meet the exacting demands of the food industry.

Applications of Breadcrumb Products

Breadcrumb products find extensive applications across various sectors within the food industry, owing to their versatile nature and wide-ranging benefits. Breadcrumb itself is a crucial component in many culinary preparations, providing texture, flavor, and functional benefits in both traditional and modern cooking techniques.

In industrial settings, Breadcrumb is used prominently in the production of processed foods such as breaded meats, seafood, and vegetables. These products are favored for their ability to enhance crispiness and mouthfeel, thus improving overall consumer satisfaction. The use of specialized crushing equipment ensures that the breadcrumbs maintain consistent quality and texture, crucial for achieving uniform coatings and optimal frying results.

In the realm of food service, Breadcrumb plays a vital role in enhancing the visual appeal and texture of dishes served in restaurants and catering operations. From enhancing the crunchiness of fried foods to serving as a binder in meatballs and patties, the versatility of Breadcrumb products allows chefs to innovate while maintaining culinary consistency.

Furthermore, Breadcrumb products have found niche applications in the pet food industry, where they serve as functional ingredients in formulations for pet treats and supplements. This underscores the adaptability of Breadcrumb production to meet diverse consumer demands across different sectors, highlighting its importance beyond traditional culinary applications.

Maintenance Tips for Crushing Equipment

Effective maintenance of crushing equipment is essential to ensure consistent performance and prolong operational lifespan in food processing facilities. Breadcrumb production relies heavily on the efficiency and reliability of the crushing equipment, which requires regular upkeep and attention to detail.

Firstly, routine cleaning procedures are critical to prevent contamination and ensure product quality. Equipment surfaces should be cleaned thoroughly using approved sanitizers and detergents, paying particular attention to areas prone to residue buildup.

Secondly, conducting regular inspections and assessments of the crushing equipment helps identify potential issues before they escalate. This proactive approach allows for timely repairs and adjustments, minimizing downtime and optimizing production efficiency.

Additionally, lubrication of moving parts is essential to reduce friction and wear. Lubricants should be applied according to manufacturer recommendations to maintain optimal performance and prevent mechanical failures.

Lastly, staff training and adherence to safety protocols are paramount in maintaining crushing equipment. Operators should be adequately trained in equipment operation, maintenance procedures, and safety measures to mitigate risks and ensure workplace safety standards are met.

Safety Measures in Breadcrumb Production

Breadcrumb production is a precise process in the realm of food machinery, emphasizing both efficiency and safety. Breadcrumb Crushing Production involves several critical safety measures to ensure product integrity and worker well-being.

Firstly, the machinery used in Breadcrumb Crushing Production must adhere to stringent safety standards. This includes regular maintenance to prevent malfunctions that could compromise worker safety or product quality. Manufacturers are continually innovating to integrate advanced safety features into breadcrumb crushing machines, such as emergency stop mechanisms and protective guards.

Secondly, training and supervision are paramount. Operators handling breadcrumb crushing machines should undergo comprehensive training to operate the equipment safely and efficiently. This training covers not only machine operation but also maintenance procedures and emergency protocols. Supervisors play a crucial role in ensuring that operators adhere to safety guidelines at all times.

Thirdly, personal protective equipment (PPE) is mandatory. Workers involved in breadcrumb production must wear appropriate PPE, including gloves, safety goggles, and in some cases, ear protection. This equipment not only safeguards against physical injury but also protects against potential allergens or contaminants present in the breadcrumb processing environment.

Lastly, maintaining a clean and organized workspace is essential for safety. Proper sanitation practices mitigate the risk of cross-contamination and ensure a hygienic production environment. Regular cleaning schedules and sanitation audits help uphold these standards, contributing to both product safety and regulatory compliance in Breadcrumb Crushing Production.

Future Trends in Breadcrumb Processing

As technology advances, the future of breadcrumb processing in food machinery is poised for innovation and efficiency improvements. Breadcrumb Crushing Production is no exception, with several emerging trends shaping the industry's landscape.

One significant trend is the integration of automation and robotics. Automated systems streamline breadcrumb production processes, from ingredient mixing to final crushing stages. Robotics enhance precision and consistency while reducing labor costs and human error, making production more efficient and scalable.

Another trend is the emphasis on sustainability. Manufacturers are increasingly adopting eco-friendly practices in breadcrumb production. This includes optimizing energy use in machinery, reducing waste generation, and exploring biodegradable packaging solutions. Sustainability initiatives not only appeal to environmentally conscious consumers but also align with global efforts towards greener manufacturing practices.

Furthermore, advancements in machine learning and AI are transforming breadcrumb processing. AI algorithms can analyze production data in real-time, optimizing production parameters for improved efficiency and quality control. Predictive maintenance powered by AI also minimizes downtime by detecting potential equipment issues before they escalate.

Lastly, there is a growing demand for customizable breadcrumb solutions. Food manufacturers seek versatile machinery capable of producing breadcrumbs of varying textures and sizes to meet diverse consumer preferences. This trend drives innovation in machine design, focusing on flexibility and adaptability to cater to evolving market demands.

In conclusion, Breadcrumb Crushing Production is undergoing significant advancements driven by technological innovation and a focus on safety and sustainability. These trends promise to revolutionize the industry, ensuring efficient, safe, and environmentally responsible breadcrumb processing in the years to come.

Reference

1.Baker Perkins - bakerperkins.com

2.GEA Group - gea.com

3.Heat and Control - heatandcontrol.com

4.Hosokawa Micron - hosokawamicron.com

5.Fritsch Group - fritsch-group.com

Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines