- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Company News> The Ultimate Factory Certification Fermented Japanese Style Breadcrumb Guide to 2024

The Ultimate Factory Certification Fermented Japanese Style Breadcrumb Guide to 2024

2024-06-25 17:21:54Overview of Factory Certification Standards

Factory certification is a critical component in the food processing industry, ensuring that facilities meet stringent regulatory requirements and maintain high-quality production standards. Certification involves a comprehensive review of a factory’s processes, equipment, and hygiene practices to guarantee that the end products are safe for consumption. This is especially crucial for specialized products such as Factory Certification Fermented Japanese Style Breadcrumb.

Achieving factory certification involves adhering to various international standards, such as ISO 22000, HACCP, and GMP. These standards cover everything from ingredient sourcing and handling to production methods and packaging. For factories producing Factory Certification Fermented Japanese Style Breadcrumb, meeting these standards is essential to ensure that the fermentation process is controlled and consistent, producing a high-quality breadcrumb that meets consumer expectations.

Certified factories undergo regular audits and inspections to maintain their status. This continuous oversight ensures that any potential issues are identified and addressed promptly. For the production of Factory Certification Fermented Japanese Style Breadcrumb, regular certification audits ensure that the fermentation process remains sanitary and efficient, resulting in a product that adheres to the highest safety and quality standards.

Importance of Factory Certification in Food Processing

Factory certification plays a pivotal role in the food processing industry by guaranteeing product safety and quality. For manufacturers of Factory Certification Fermented Japanese Style Breadcrumb, certification signifies that their production processes are aligned with international safety standards, which is crucial for consumer trust and market acceptance.

Certified factories benefit from enhanced operational efficiencies. The rigorous standards required for certification often lead to the implementation of advanced technologies and improved production practices. For example, in producing Factory Certification Fermented Japanese Style Breadcrumb, certified facilities may use state-of-the-art fermentation equipment and techniques, ensuring consistent product quality and safety.

Moreover, factory certification facilitates market access and compliance with regulatory requirements. In many countries, only certified factories can export food products. For the Factory Certification Fermented Japanese Style Breadcrumb industry, this means that certified manufacturers can access a broader market, boosting their competitive edge and profitability.

Lastly, factory certification enhances brand reputation. Consumers are increasingly aware of food safety issues and are more likely to trust products from certified manufacturers. For producers of Factory Certification Fermented Japanese Style Breadcrumb, certification not only ensures compliance with safety standards but also serves as a marketing tool to attract quality-conscious consumers.

Steps to Achieve Factory Certification

Achieving Factory Certification for producing Fermented Japanese Style Breadcrumb involves a series of meticulously planned steps to ensure compliance with industry standards and regulations. Here are the four essential steps:

Initial Assessment and Gap Analysis: Begin by conducting a thorough initial assessment of the current factory operations. This involves identifying any gaps between existing practices and the requirements for Factory Certification. Key areas of focus include sanitation, equipment maintenance, and documentation processes specifically tailored for Fermented Japanese Style Breadcrumb production.

Implementation of Quality Management Systems (QMS): Implement a robust Quality Management System that aligns with international standards. This system should encompass every aspect of production, from sourcing raw materials to final product packaging. Special attention must be given to the fermentation process, ensuring that the unique characteristics of Fermented Japanese Style Breadcrumb are maintained without compromising quality or safety.

Employee Training and Competency: Ensure that all employees involved in the production process are adequately trained. This includes understanding the specific requirements of producing Fermented Japanese Style Breadcrumb, operating machinery, and adhering to safety protocols. Regular training sessions and competency assessments are crucial for maintaining high standards and preparing for certification audits.

Internal Audits and Continuous Improvement: Conduct regular internal audits to monitor compliance with the established QMS. These audits should identify areas for improvement and ensure that corrective actions are implemented promptly. Continuous improvement initiatives should be part of the factory culture, focusing on enhancing efficiency, reducing waste, and ensuring the consistent quality of Fermented Japanese Style Breadcrumb.

Key Regulations for Japanese Style Breadcrumb Production

To ensure the production of high-quality Fermented Japanese Style Breadcrumb, factories must adhere to several key regulations. The table below outlines these regulations and their specific requirements:

|

Regulation Area |

Requirement Details |

Importance |

|

Sanitation and Hygiene |

Maintain strict cleanliness in all production areas, including regular sanitization of equipment and surfaces. |

Prevents contamination and ensures the safety of Fermented Japanese Style Breadcrumb. |

|

Fermentation Control |

Precisely monitor and control fermentation parameters such as temperature, humidity, and time. |

Ensures the unique flavor and texture of Fermented Japanese Style Breadcrumb are achieved. |

|

Raw Material Sourcing |

Source high-quality raw materials that meet specified safety and quality standards. |

Guarantees the base quality of the Fermented Japanese Style Breadcrumb. |

|

Traceability and Documentation |

Maintain comprehensive records of all production stages, from raw material receipt to final product shipment. |

Facilitates traceability and accountability in the event of any quality issues. |

|

Quality Testing and Assurance |

Implement regular quality testing protocols, including microbiological and sensory analysis. |

Ensures that each batch of Fermented Japanese Style Breadcrumb meets established standards. |

|

Employee Health and Safety |

Adhere to occupational health and safety regulations, providing protective gear and training for all staff. |

Ensures a safe working environment and reduces the risk of accidents. |

|

Environmental Regulations |

Comply with environmental regulations concerning waste disposal and emissions. |

Minimizes the environmental impact of the production process. |

|

Packaging and Labeling |

Ensure packaging materials are safe and labels accurately reflect the product contents and expiration dates. |

Provides consumers with necessary information and maintains product integrity. |

Fermentation Process in Breadcrumb Manufacturing

In the realm of industrial food machinery, the fermentation process plays a pivotal role in enhancing the quality and nutritional profile of Japanese style breadcrumbs. Fermentation transforms raw ingredients into breadcrumbs with heightened flavor complexity and improved digestibility.

The process begins with the careful selection of ingredients, including high-quality flour, water, yeast, and a precise blend of enzymes. These ingredients are mixed in specialized fermentation tanks designed to maintain optimal temperature and humidity levels. Fermentation progresses under controlled conditions for a specified period, typically 12 to 24 hours, allowing beneficial microorganisms to proliferate and metabolize sugars.

During this period, enzymatic activity breaks down complex carbohydrates into simpler sugars, enriching the dough's flavor profile. The development of gases, primarily carbon dioxide, creates a light and airy texture crucial for the final breadcrumb product. This controlled fermentation process not only improves texture but also extends the shelf life of the breadcrumbs by inhibiting mold growth.

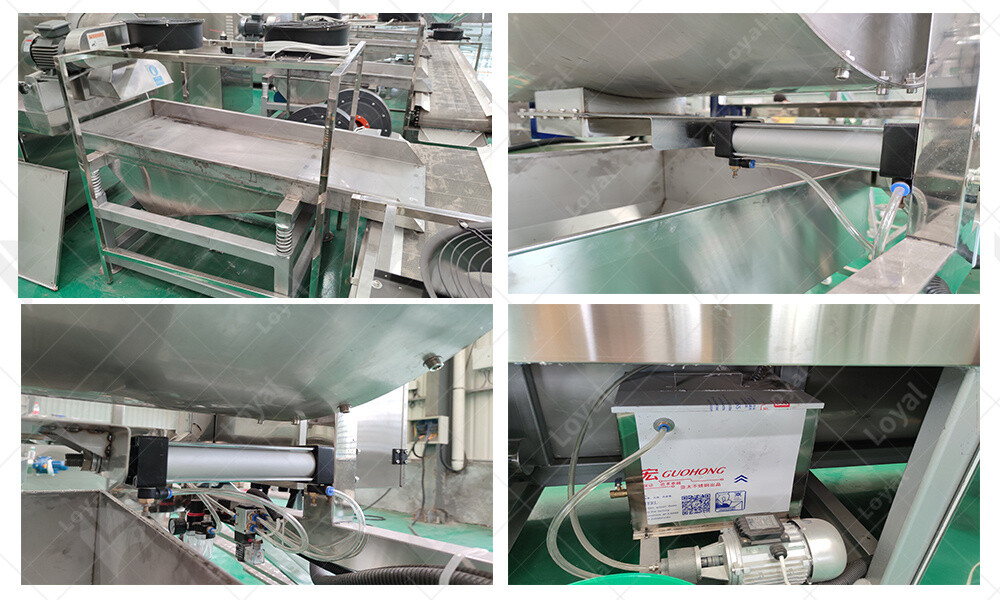

Once fermentation reaches its peak, the dough undergoes a careful monitoring process to ensure consistency and quality. Technological advancements in monitoring equipment enable real-time data collection on pH levels, temperature variations, and microbial activity, ensuring adherence to stringent industry standards.

Best Practices for Factory Certification Compliance

Achieving and maintaining Factory Certification requires strict adherence to best practices in food production and safety protocols. This section explores key strategies to ensure compliance with certification standards.

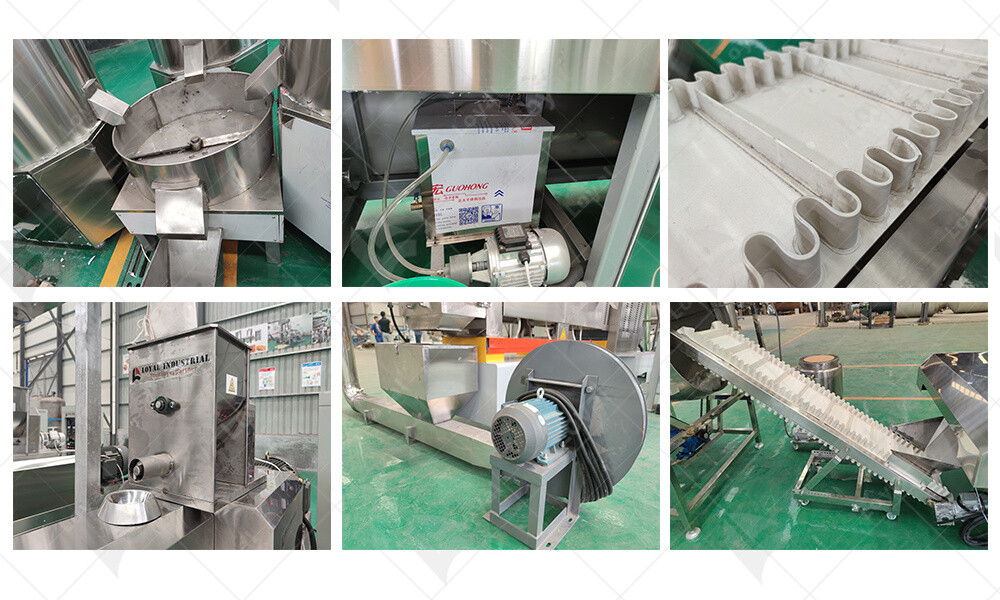

Infrastructure and Equipment Upgrades: Investing in state-of-the-art machinery for Japanese Style Breadcrumb production is crucial for meeting Factory Certification requirements. Equipment should be regularly calibrated and maintained to optimize performance and minimize downtime.

Employee Training and Certification: Properly trained staff is essential to maintaining compliance with Factory Certification standards. Training programs should cover hygiene practices, equipment operation, and emergency procedures to ensure a safe working environment.

Traceability and Documentation: Implementing robust traceability systems is essential for Factory Certification compliance. Documentation should include batch records, ingredient sourcing details, and quality control checkpoints to track each stage of production.

Continuous Improvement: Regular audits and reviews of production processes are essential for identifying areas of improvement. By implementing corrective actions promptly, factories can enhance operational efficiency and maintain Factory Certification status.

Innovations in Fermented Breadcrumb Processing

In the realm of industrial food machinery, the process of fermented breadcrumb production has seen remarkable advancements in recent years. Traditionally, breadcrumb production involved simple grinding and toasting of bread. However, with the advent of sophisticated machinery, manufacturers are now integrating fermentation into this process, aiming to enhance both flavor profiles and nutritional value.

One notable innovation is the use of automated fermentation chambers. These chambers control temperature and humidity levels precisely, optimizing conditions for yeast or bacterial cultures essential in fermenting breadcrumbs. This automated approach not only ensures consistency in fermentation but also boosts efficiency, reducing production time and costs associated with manual monitoring.

Another pivotal advancement lies in the integration of AI-driven quality control systems. These systems utilize advanced sensors to monitor fermentation parameters in real-time. By analyzing data such as pH levels and CO2 production rates, manufacturers can adjust fermentation conditions promptly, ensuring the desired quality and safety standards of fermented Japanese style breadcrumb.

Furthermore, the incorporation of modular processing units has revolutionized production flexibility. Manufacturers can now easily scale production volumes and adapt to varying market demands without significant downtime. This modularity extends beyond fermentation to subsequent stages like drying and packaging, offering a comprehensive solution for streamlined breadcrumb production.

Challenges in Factory Certification for Food Industries

Factory certification for food industries, particularly in the context of fermented breadcrumb production, presents several intricate challenges that demand meticulous attention. One of the primary hurdles is navigating the complex landscape of international food safety regulations. Certifying bodies impose stringent standards to ensure products meet safety, hygiene, and labeling requirements across global markets.

Moreover, achieving and maintaining certification necessitates substantial investments in equipment and infrastructure. For instance, facilities must implement state-of-the-art machinery capable of meeting hygiene standards and supporting efficient production processes. These investments are crucial not only for compliance but also for upholding consumer trust and safeguarding brand reputation.

Additionally, maintaining consistency in product quality poses a perpetual challenge. Variations in raw materials, environmental factors, and operational processes can impact the final product's characteristics. To mitigate these risks, manufacturers employ robust quality assurance protocols encompassing regular testing, calibration of equipment, and continuous training of personnel involved in Japanese style breadcrumb production.

Furthermore, amidst evolving consumer preferences and heightened awareness of sustainability, certification processes increasingly scrutinize environmental impact. Implementing eco-friendly practices throughout the production cycle, from sourcing ingredients to managing waste, is imperative. It not only aligns with regulatory expectations but also resonates with conscientious consumers seeking products that minimize ecological footprints.

Benefits of Certified Fermented Japanese Style Breadcrumbs

Certified Factory Certification Fermented Japanese Style Breadcrumb offers unparalleled advantages in modern food processing. These breadcrumbs are meticulously crafted under stringent quality controls, ensuring optimal taste and texture in various culinary applications. The fermentation process enhances flavor profiles, giving dishes a distinct umami richness that consumers increasingly demand. Industrial food machinery plays a pivotal role in maintaining consistency and efficiency throughout production, meeting the exacting standards required for certification.

As consumer preferences shift towards healthier, artisanal products, Factory Certification Fermented Japanese Style Breadcrumb stands out for its natural fermentation process. This method not only preserves nutritional value but also contributes to a more digestible end product, catering to health-conscious markets globally. Incorporating advanced food processing machinery ensures that each batch meets regulatory benchmarks, essential for securing and maintaining certification in a competitive market.

In the realm of food safety and traceability, Factory Certification Fermented Japanese Style Breadcrumb excels. Rigorous production protocols, monitored by state-of-the-art equipment, guarantee that each breadcrumb complies with international safety standards. This level of certification instills confidence in consumers and businesses alike, solidifying its position as a preferred choice for chefs, manufacturers, and distributors seeking reliability and quality assurance.

Future Trends in Factory Certification and Breadcrumb Production

Looking ahead to 2024 and beyond, the landscape of Factory Certification Fermented Japanese Style Breadcrumb production is poised for significant advancements. Innovations in food machinery technology continue to streamline manufacturing processes, enhancing productivity without compromising quality. Automation and AI-driven systems play pivotal roles in optimizing production lines, ensuring consistency in breadcrumb texture and flavor.

The future of Factory Certification Fermented Japanese Style Breadcrumb production also underscores sustainability. Manufacturers increasingly adopt eco-friendly practices, minimizing waste and energy consumption throughout the manufacturing process. Advanced machinery facilitates efficient resource utilization, aligning with global efforts towards environmental stewardship and corporate responsibility.

Market expansion is another key trend shaping the industry. As demand for authentic, high-quality breadcrumbs grows, certified Factory Certification Fermented Japanese Style Breadcrumb emerges as a cornerstone of culinary innovation. Strategic partnerships and global distribution networks supported by robust food machinery infrastructure enable manufacturers to meet diverse consumer preferences worldwide.

In conclusion, Factory Certification Fermented Japanese Style Breadcrumb represents the pinnacle of quality and innovation in breadcrumb production. Leveraging cutting-edge food machinery and adhering to stringent certification standards, manufacturers are poised to capitalize on evolving consumer trends while maintaining a commitment to excellence and sustainability.

Reference

1.Baker Perkins - bakerperkins.com

2.GEA Group - gea.com

3.Heat and Control - heatandcontrol.com

4.Hosokawa Micron - hosokawamicron.com

5.Fritsch Group - fritsch-group.com

Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines