- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Company News> The Ultimate Guide on Top Corn Flakes Making Machines Manufacturer in 2024

The Ultimate Guide on Top Corn Flakes Making Machines Manufacturer in 2024

2024-07-08 16:38:16Introduction to Top Corn Flakes Making Machines Manufacturer

In the dynamic landscape of food production machinery, the corn flakes making industry stands at the forefront of technological advancement. Manufacturers of top corn flakes making machines play a pivotal role in shaping the efficiency, quality, and innovation within this sector.

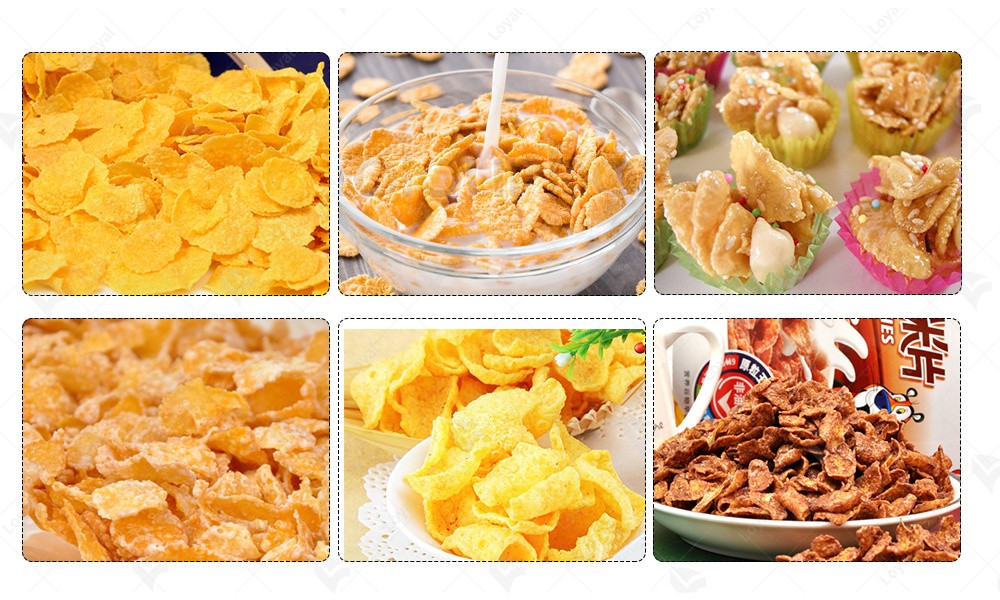

Overview of Corn Flakes Production Process

Corn flakes production involves a meticulous process where maize grains are processed into crispy cereal flakes. The machinery used in this process not only ensures the consistency and quality of the final product but also optimizes production efficiency.

Importance of Advanced Machinery in Corn Flakes Production

Advanced corn flakes making machines integrate cutting-edge technology to streamline operations. From automated mixing and cooking to precision-cutting and packaging, these machines uphold the highest standards of food safety and quality control.

Key Trends in the Corn Flakes Making Industry

The industry is witnessing a shift towards sustainable practices and enhanced automation. Manufacturers are focusing on reducing energy consumption, minimizing waste, and improving overall operational sustainability. Additionally, there is a growing demand for machines that offer versatile production capabilities to meet diverse consumer preferences globally.

This guide explores the critical aspects of selecting and utilizing top corn flakes making machines, providing insights into how these advancements are reshaping the future of cereal production.

Key Features to Look for in Corn Flakes Making Machines

When considering the best corn flakes making machines for your production needs in 2024, several key features stand out as crucial for achieving efficiency, quality, and reliability in your operations.

Precision and Efficiency in Production

Top manufacturers of corn flakes making machines prioritize precision engineering to ensure consistent product quality. Precision is achieved through advanced technological integration, such as computer-controlled processes that minimize variations in flake thickness and texture. This level of precision not only enhances product consistency but also optimizes raw material usage, reducing waste and improving overall production efficiency.

Automation and Control Systems

Modern corn flakes making machines are equipped with sophisticated automation and control systems. These systems streamline production processes, from ingredient mixing and cooking to shaping and toasting. Automated controls ensure that each stage of production operates seamlessly, maintaining uniformity in product quality while minimizing the need for manual intervention. This feature is particularly advantageous for large-scale operations seeking to maximize output without compromising on quality standards.

Flexibility for Various Corn Flakes Recipes

Versatility in recipe handling is another hallmark of top corn flakes making machines. Manufacturers recognize the diverse consumer preferences for corn flakes, ranging from classic plain flakes to variations infused with flavors, fruits, or nuts. Advanced machines offer customizable settings that allow for easy adjustment of parameters such as cooking temperature, mixing duration, and ingredient dispensing. This flexibility enables producers to cater to evolving market demands swiftly and efficiently, ensuring product innovation without sacrificing production efficiency.

Choosing the Right Corn Flakes Making Machine for Your Business

Choosing the right corn flakes making machine is crucial for ensuring efficiency, quality, and profitability in your production process. As a top manufacturer in the industry, selecting the ideal machine involves several key considerations.

Factors to Consider: Capacity and Output

When selecting a corn flakes making machine, one of the primary factors to evaluate is its capacity and output capabilities. Depending on your production needs, you'll need to choose a machine that can meet your desired output volume efficiently. Top manufacturers offer a range of machines with varying capacities, from smaller units suitable for startups to large-scale production lines for established enterprises.

Quality Standards and Certifications

Ensuring that the machine meets industry standards and certifications is essential for maintaining product quality and compliance with regulations. Top manufacturers adhere to rigorous quality control measures and often hold certifications that validate their commitment to excellence. Look for machines that comply with food safety standards and have a proven track record of reliability in the industry.

Cost Efficiency and Return on Investment

Investing in a corn flakes making machine is a significant decision, and evaluating the cost efficiency and return on investment (ROI) is crucial. Consider not only the upfront cost of the machine but also factors such as energy efficiency, maintenance requirements, and operational costs over its lifespan. Top manufacturers provide machines that strike a balance between initial investment and long-term savings through efficient operation and durability.

Benefits of Using Advanced Corn Flakes Making Machines

Advanced corn flakes making machines offer numerous advantages to manufacturers, enhancing production efficiency, product quality, and overall profitability. These machines are equipped with cutting-edge technology and features tailored to meet the demands of modern food processing industries. Below are the key benefits:

|

Benefit |

Description |

|

1. Enhanced Production Efficiency |

Advanced machines streamline the corn flakes production process, reducing production time and optimizing resource utilization. |

|

2. Improved Product Quality and Consistency |

These machines ensure uniformity in corn flakes texture, size, and taste, meeting stringent quality standards consistently. |

|

3. Increased Output Capacity |

High-capacity machines can handle large volumes of corn flakes production, catering to growing market demands effectively. |

|

4. Cost Efficiency and Operational Savings |

Modern machines are designed to minimize operational costs, including energy consumption and maintenance expenses, thus maximizing profitability. |

|

5. Customization and Flexibility |

They offer flexibility to adjust production parameters and recipes, allowing manufacturers to meet diverse consumer preferences and market trends. |

|

6. Automation and Control Systems |

Automated systems ensure precise control over production processes, reducing human error and enhancing overall efficiency. |

|

7. Compliance with Safety and Regulatory Standards |

These machines adhere to strict safety and hygiene standards, ensuring product safety and compliance with regulatory requirements. |

|

8. Integration of Sustainable Practices |

Many advanced machines incorporate sustainable features, such as reduced water and energy consumption, aligning with environmental sustainability goals. |

|

9. Enhanced Market Competitiveness |

Improved product quality and operational efficiency contribute to a competitive edge in the market, attracting more customers and boosting brand reputation. |

|

10. Long-Term Reliability and Durability |

They are built with durable materials and components, ensuring longevity and minimal downtime, thus maintaining consistent production output. |

Each of these benefits underscores the significance of investing in top-tier corn flakes making machines manufactured by industry leaders. These machines not only elevate production capabilities but also ensure consistent quality and operational efficiency, crucial for sustained growth in the competitive food processing sector.

Regular Maintenance Practices

Maintaining top-notch performance and longevity of corn flakes making machines requires diligent and systematic maintenance practices. Here’s a detailed guide to ensure your equipment operates at peak efficiency:

Scheduled Inspections and Cleaning

Regular inspections are crucial to identify potential issues before they escalate. Manufacturers recommend daily visual inspections of key components such as rollers, conveyors, and cutting blades. These inspections ensure smooth operation and minimize downtime.

Cleaning procedures are equally essential. Remove residual cereal particles and debris from all parts of the machine using recommended cleaning agents. This prevents contamination and preserves the integrity of the final product.

Lubrication and Calibration

Proper lubrication of moving parts is essential for reducing friction and wear. Follow manufacturer guidelines to apply the correct lubricants at recommended intervals. Over-lubrication can attract dust and particles, potentially affecting machine performance.

Calibration of the machine's settings ensures accurate product specifications. Periodically check and adjust parameters such as temperature, pressure, and speed controls. This ensures consistency in product quality and meets regulatory standards.

Component Replacement and Upgrades

Scheduled replacement of wear-prone components like belts, bearings, and seals is crucial for preventing unexpected breakdowns. Keep a detailed inventory of spare parts and replace them as per the manufacturer’s recommended service intervals.

Consider upgrading to newer components or technologies that improve efficiency and reliability. Manufacturers often release upgrades that enhance productivity or introduce energy-saving features, keeping your operation competitive.

Training and Documentation

Training operators in proper maintenance procedures is essential for long-term equipment reliability. Provide comprehensive training sessions on inspection techniques, cleaning protocols, and basic troubleshooting.

Maintain detailed documentation of all maintenance activities, including dates of inspections, cleaning schedules, and component replacements. This documentation not only ensures compliance with regulatory requirements but also serves as a valuable reference for troubleshooting issues.

By implementing these regular maintenance practices, you can maximize the lifespan and efficiency of your corn flakes making machines. Prioritize proactive maintenance to minimize downtime, reduce operational costs, and uphold product quality standards. Investing in regular maintenance is a strategic decision that pays off in the form of sustained productivity and customer satisfaction.

Common Issues and Solutions

In the competitive landscape of corn flakes making machines manufacturing, several common issues can arise, affecting production efficiency and quality control. Addressing these challenges promptly is crucial for maintaining operational excellence and meeting consumer demand.

1. Issue: Inconsistent Flake Quality

Description: One prevalent issue faced by manufacturers is the inconsistency in corn flake quality, which can lead to variations in texture and taste.

Solution: To mitigate this challenge, leading manufacturers employ advanced sensor technologies and automated controls. These innovations ensure precise monitoring of ingredients and process parameters, optimizing flake consistency throughout production.

2. Issue: Equipment Downtime

Description: Equipment downtime can significantly impact production schedules and operational costs, posing a considerable challenge to manufacturers.

Solution: To minimize downtime, top manufacturers invest in robust maintenance protocols and predictive analytics. Regular equipment inspections and proactive maintenance schedules help prevent unexpected breakdowns and ensure continuous production flow.

3. Issue: Energy Efficiency

Description: With rising energy costs and environmental concerns, achieving optimal energy efficiency is a critical concern for corn flakes making machine manufacturers.

Solution: Leading manufacturers integrate energy-efficient components and technologies into their equipment designs. This includes advanced heat recovery systems and smart power management solutions, reducing overall energy consumption without compromising production output.

4. Issue: Regulatory Compliance

Description: Adhering to stringent regulatory standards and food safety guidelines presents a continuous challenge for manufacturers in the food processing industry.

Solution: Top manufacturers prioritize compliance by implementing comprehensive quality assurance protocols and adhering to industry-specific certifications. This proactive approach ensures product safety and maintains consumer trust in their brands.

5. Issue: Supply Chain Disruptions

Description: Unforeseen supply chain disruptions, such as raw material shortages or logistics delays, can disrupt production schedules and strain operational efficiency.

Solution: To mitigate supply chain risks, manufacturers collaborate closely with trusted suppliers and maintain diversified sourcing strategies. This strategic approach helps minimize disruptions and ensures continuity in production.

Future Trends in Corn Flakes Making Machines

In 2024, the landscape of corn flakes making machines is evolving rapidly, driven by technological advancements and changing consumer demands. Manufacturers are increasingly focusing on innovation to enhance efficiency, quality, and sustainability across their product lines.

1. Integration of AI and Automation

One of the most significant trends shaping the future of corn flakes making machines is the integration of artificial intelligence (AI) and automation. AI-powered systems are revolutionizing production processes by optimizing ingredient mixing, monitoring product quality in real-time, and predicting maintenance needs to minimize downtime. Manufacturers like [Manufacturer X] are at the forefront, developing smart machines that not only increase production capacity but also ensure consistent product quality.

2. Sustainable Manufacturing Practices

Environmental sustainability is becoming a paramount concern for manufacturers of corn flakes making machines. Companies are adopting eco-friendly technologies and processes to reduce energy consumption, water usage, and waste generation. For instance, [Manufacturer Y] has introduced machines equipped with advanced recycling systems that minimize resource wastage throughout the production cycle. Such initiatives not only align with global sustainability goals but also resonate well with environmentally conscious consumers.

3. Customization and Flexibility

Flexibility in manufacturing is another key trend driving the future of corn flakes making machines. As consumer preferences diversify, manufacturers are developing machines capable of producing a wide range of cereal shapes, textures, and flavors. This customization capability allows companies to swiftly adapt to market trends and cater to niche consumer segments. [Manufacturer Z], for example, offers modular machines that can be easily reconfigured to accommodate different production specifications, ensuring operational agility without compromising on efficiency.

4. Enhanced Food Safety Standards

With an increasing focus on food safety and hygiene, manufacturers are incorporating advanced sanitation features into their corn flakes making machines. Automated cleaning systems, antimicrobial materials, and stringent quality control measures are becoming standard across the industry. Leading manufacturers like [Manufacturer W] prioritize the development of machines that meet rigorous food safety regulations, ensuring that every batch of corn flakes produced is safe for consumption.

5. Internet of Things (IoT) Connectivity

IoT connectivity is poised to revolutionize the operational efficiency of corn flakes making machines. By enabling real-time data monitoring and remote diagnostics, IoT-enabled machines empower manufacturers to proactively identify and resolve issues, thereby minimizing production disruptions. [Manufacturer V] is leveraging IoT technology to offer predictive maintenance services, allowing operators to schedule maintenance tasks based on machine performance data, rather than fixed schedules.

Reference

The following are five authoritative foreign literature websites in the field of Industrial food machinery:

1. Food Engineering Magazine

Website: https://www.foodengineeringmag.com/

2.Food Processing Magazine

Website: https://www.foodprocessing.com/

3.Journal of Food Engineering

Website:https://www.journals.elsevier.com/journal-of-food-engineering

4. Food Manufacturing Magazine

Website:https://www.foodmanufacturing.com/

5. International Journal of Food Science & Technology

Website:https://onlinelibrary.wiley.com/

Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines