- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Processing> How To Choose The Best red dates Microwave Sterilizing Machine: 2025 Buyer’s Guide

How To Choose The Best red dates Microwave Sterilizing Machine: 2025 Buyer’s Guide

2025-08-11 17:22:58If you want to know more story about LOYAL brand, here can help you - https://www.facebook.com/foodmachineloyal

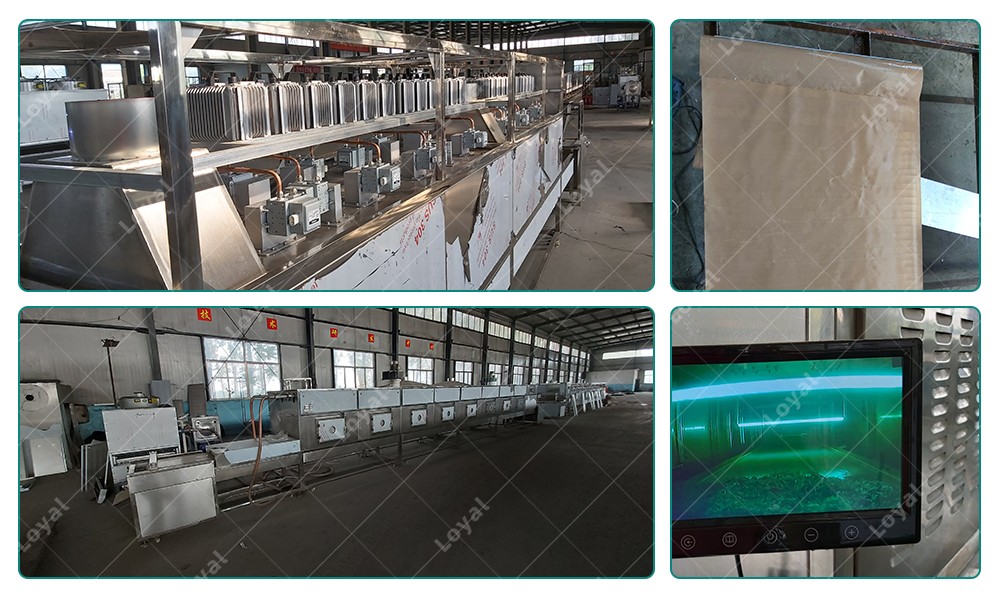

Introduction to Red Dates Microwave Sterilizing Machine

In recent years, the food industry has seen a dramatic shift towards more advanced and efficient sterilization technologies, and one of the most notable innovations is the Red Dates Microwave Sterilizing Machine. As consumer demand for safe, high-quality food continues to rise, especially in the realm of dried fruits, this technology offers an essential solution for food manufacturers. The Red Dates Microwave Sterilizing Machine represents a breakthrough in sterilization, particularly in the processing of red dates—an increasingly popular ingredient known for its health benefits.

Traditionally, red dates, whether fresh or dried, have been sterilized using high-temperature methods such as steam or hot air. While effective, these conventional techniques can often result in a loss of nutrients, flavor, and texture. The advent of microwave sterilization, however, has significantly improved this process. By using controlled microwave energy, the Red Dates Microwave Sterilizing Machine allows for faster and more efficient sterilization, preserving the natural quality of red dates while ensuring food safety.

This technology is not just a luxury but a necessity for modern food production, especially for those in the commercial market, where efficiency, quality, and cost-effectiveness are paramount. The microwave sterilization process works by targeting moisture molecules within the red dates, rapidly generating heat that kills harmful microorganisms without compromising the fruit’s essential nutrients. This results in a higher-quality product that is both safe and nutritionally intact, giving producers a competitive edge in the market.

Advantages of Using a Red Dates Microwave Sterilizing Machine

The Red Dates Microwave Sterilizing Machine has rapidly gained traction in the food processing industry due to its unique advantages over traditional sterilization methods. As demand for high-quality, safe, and nutritious food continues to rise, food manufacturers are turning to advanced technologies like microwave sterilization to meet these needs. Below are some key advantages that make the Red Dates Microwave Sterilizing Machine an essential tool for modern food processing.

1.Enhanced Nutrient Preservation

One of the most significant benefits of using a microwave sterilizing machine is its ability to preserve the nutritional content of red dates. Traditional sterilization methods, such as hot water or steam treatments, often expose the food to high temperatures for extended periods, resulting in the degradation of heat-sensitive nutrients like vitamins, antioxidants, and minerals. In contrast, microwave sterilization uses a rapid, precise heating process that minimizes nutrient loss while still effectively eliminating harmful microorganisms. This ensures that red dates retain their full nutritional value, offering consumers a healthier product.

2.Energy Efficiency and Cost Savings

Energy consumption is a critical factor in the operational costs of food processing facilities. Traditional sterilization methods, such as pasteurization or autoclaving, often require large amounts of energy and time to heat the entire system. Microwave sterilization, however, directly targets the moisture within the red dates, heating them from the inside out. This localized heating reduces the need for extensive energy expenditure and minimizes overall processing time. The result is a more energy-efficient process that lowers both operating costs and environmental impact, providing a sustainable solution for food manufacturers.

3.Faster Processing Time

Time is a crucial factor in the food processing industry, especially when dealing with perishable products like red dates. Conventional sterilization methods can take several hours to complete, depending on the size and type of food being processed. The Red Dates Microwave Sterilizing Machine significantly shortens this time by rapidly heating the food to the desired sterilization temperature. As a result, the machine can handle larger volumes of red dates in a shorter period, improving overall production efficiency and meeting the growing demand for processed foods.

4.Improved Product Quality

Microwave sterilization is known for its ability to produce more consistent and uniform heating, which is particularly beneficial when working with delicate foods like red dates. Since microwaves penetrate the food evenly, there is less chance of overcooking or uneven sterilization. This ensures that the texture, color, and flavor of the red dates are maintained, resulting in a high-quality finished product that meets consumer expectations. Additionally, the precise control over temperature and time helps prevent the loss of the dates' natural sweetness and aroma.

5.Reduced Chemical Usage

Unlike some traditional sterilization methods, which may require the use of chemicals to achieve the desired sterilization effect, microwave sterilization eliminates the need for additional chemicals. This is particularly important for consumers who are increasingly concerned about food safety and the presence of chemical residues in processed foods. By relying solely on microwave energy, the Red Dates Microwave Sterilizing Machine offers a more natural and chemical-free approach to sterilization, ensuring that the product remains safe and free from any unwanted contaminants.

6.Increased Shelf Life and Safety

By effectively sterilizing red dates without compromising their quality, microwave sterilization extends the shelf life of the product. The elimination of harmful microorganisms during the process ensures that the dates remain safe for consumption over an extended period, reducing the risk of spoilage and contamination. The ability to maintain product safety and shelf stability is crucial in today's global food market, where consumers demand longer-lasting, safe food products.

7.Automation and Ease of Use

Modern Red Dates Microwave Sterilizing Machines are designed with user-friendly interfaces and automated controls, making the sterilization process more efficient and less labor-intensive. These machines can be programmed to operate at specific temperatures, times, and humidity levels, ensuring optimal sterilization conditions with minimal supervision. This automation not only improves the consistency of the sterilization process but also reduces the risk of human error, increasing the overall reliability and safety of the system.

Future Trends in Red Dates Microwave Sterilizing Machines

The Red Dates Microwave Sterilizing Machine represents a technological leap forward in the food processing industry. As demand for high-quality, nutritious, and safe food products increases, innovations in microwave sterilization technology are set to play a pivotal role in shaping the future of red date processing. Several key trends are emerging that are likely to redefine the landscape of food sterilization in the years to come.

1.Technological Advancements: Automation and Precision

One of the most significant trends in microwave sterilization technology is the increasing integration of automation and precision controls. Advanced control systems and sensors are being developed to monitor temperature, moisture, and other key factors in real time, ensuring optimal sterilization conditions for red dates. These systems will allow food manufacturers to maintain high product quality while reducing the risk of human error.

Automation is also driving the efficiency of sterilization processes. Red Dates Microwave Sterilizing Machines are becoming more autonomous, requiring minimal operator intervention. Machines can now adjust the microwave power and duration based on the specific load size and type of red dates being processed. This flexibility is crucial in meeting the demands of large-scale food production while maintaining consistent quality.

2.Increased Energy Efficiency

Energy efficiency is a growing concern in the food processing industry, and the Red Dates Microwave Sterilizing Machine is at the forefront of addressing this issue. Unlike traditional methods that rely on high-temperature steam or hot water, microwave sterilization directly heats the red dates, reducing energy consumption and minimizing heat loss. This not only reduces operational costs but also contributes to more sustainable practices by lowering the carbon footprint.

As microwave technology continues to improve, we can expect further advancements in energy efficiency, with systems optimized for even lower power consumption. This trend aligns with the broader push for more sustainable food processing practices, driven by environmental regulations and consumer demand for eco-friendly products.

3.Faster Processing Times Without Sacrificing Quality

One of the most exciting trends in microwave sterilization technology is the ongoing effort to reduce processing times while maintaining the high quality of the red dates. Traditional sterilization methods, such as hot water immersion and steam, can take several minutes to an hour to complete, depending on the load size. With Red Dates Microwave Sterilizing Machines, sterilization times can be drastically shortened, often completing the process in just a few minutes.

This reduction in processing time has several benefits, including increased production capacity, reduced energy consumption, and improved freshness retention. As technology improves, the sterilization process will become even faster, which is crucial for meeting the demands of the global food market where consumers increasingly expect fresher products with longer shelf lives.

4.Customization and Flexibility in Sterilization Parameters

As the demand for variety in food products increases, food manufacturers are looking for more customized sterilization solutions. The ability to tailor the sterilization parameters—such as microwave power, exposure time, and temperature—based on

the specific characteristics of different red dates varieties or product types is a trend that is likely to gain momentum.

With future advancements in Red Dates Microwave Sterilizing Machines, manufacturers will have more flexibility to adapt the sterilization process to suit various processing needs. Whether it's for whole red dates, dried dates, or red date-based products, the ability to fine-tune the sterilization process will ensure optimal quality and safety for each product type.

Technical Parameters Of Continuous Microwave Dryer Industrial Microwave Drying Machine |

|||||

Model |

Size LWH(Can be customized according

|

Output

|

Dewaterability |

Sterilization

|

Baking and Roasting capacity

|

LY-10KW |

5000mm825mm1750mm |

≥10KW |

10KG/Hour |

100KG/Hour |

30-50KG/Hour |

LY-20KW |

8000mm825mm1750mm |

≥20KW |

20KG/Hour |

200KG/Hour |

60-100KG/Hour |

LY-30KW |

8500mm1160mm1750mm |

≥30KW |

30KG/Hour |

300KG/Hour |

90-150 KG/Hour |

LY-40KW |

10000mm1160mm1750mm |

≥40KW |

40KG/Hour |

40KG/Hour |

120-200KG/Hour |

LY-50KW |

12500mm1160mm1750mm |

≥50KW |

50KG/Hour |

500KG/Hour |

150-250KG/Hour |

LY-60KW |

13500mm1450mm1750mm |

≥60KW |

60KG/Hour |

600KG/Hour |

180-300KG/Hour |

LY-70KW |

13500mm1500mm1750mm |

≥70KW |

70KG/Hour |

700KG/Hour |

210-350KG/Hour |

LY-80KW |

13500mm1650mm1750mm |

≥80KW |

80KG/Hour |

800KG/Hour |

240-400KG/Hour |

LY-100KW |

16800mm1650mm1750mm |

≥100KW |

100KG/Hour |

1000KG/Hour |

300-500KG/Hour |

LY-150KW |

22400mm1850mm1750mm |

≥150KW |

150KG/Hour |

1500KG/Hour |

450-750KG/Hour |

LY-200KW |

27000mm1850mm1750mm |

≥250KW |

250KG/Hour |

2500KG/Hour |

750-1250/Hour |

LY-300KW |

32000mm1850mm1750mm |

≥300KW |

300KG/Hour |

3000KG/Hour |

900-1500KG/Hour |

Power Supply |

380V±10% 50Hz±1% Three-Phase Five-Wire |

||||

Microwave Output Frequency |

2450±50Mhz |

||||

Microwave Input Apparent Power |

≤168Kva |

||||

Microwave Output Power |

≥120Kw |

||||

Microwave Power Adjustment Range |

0-30Kw(Adjustable) |

||||

Ambient Temperature |

-5-40°C |

||||

Relative Humidity |

≤80%, Surrounding Environment:No Corrosive Gas, Conductive Dust And Explosive Gas |

||||

Transmission Speed |

0-10m/Min(Adjustable) |

||||

Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines