- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Processing> Efficient 2D&3D Pellet Snack Drying Oven: Advanced Multi-Layer Continuous Baking Solution

Efficient 2D&3D Pellet Snack Drying Oven: Advanced Multi-Layer Continuous Baking Solution

2025-09-24 09:12:112D&3D Pellet Snack Drying Oven Introduction

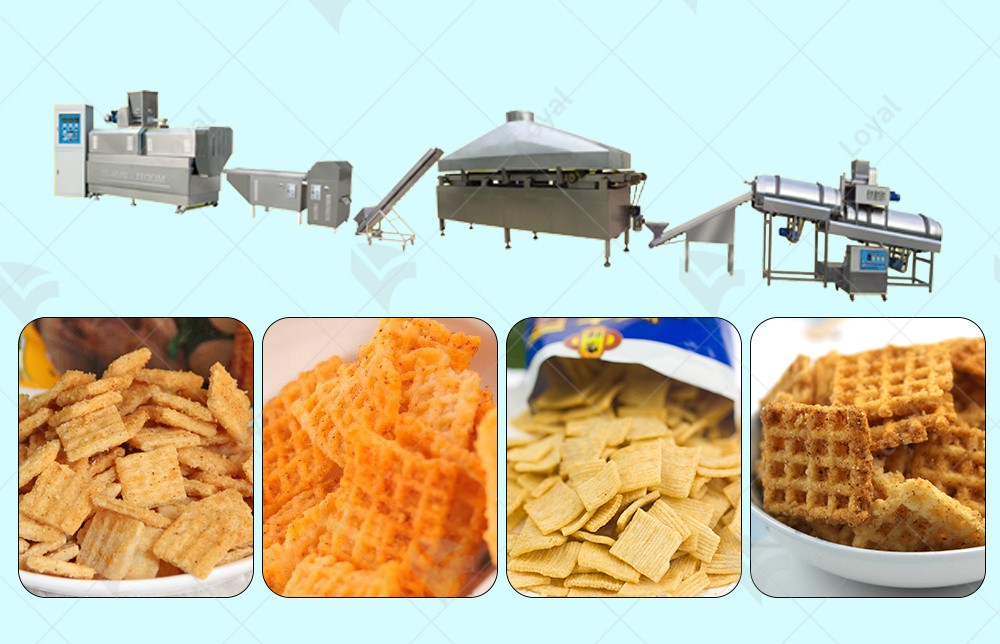

The 2D&3D Pellet Snack Drying Oven is a state-of-the-art food processing machine designed for continuous, large-scale snack production. As the global demand for pellet-based snacks grows, manufacturers require reliable and efficient drying solutions that guarantee consistent quality. This advanced drying oven integrates multi-layer continuous baking technology, ensuring uniform moisture removal while maintaining the crispness and flavor of the final product.

The machine is engineered not only to reduce energy consumption but also to enhance throughput, making it an ideal choice for snack factories aiming to scale production. With its precise temperature control and optimized airflow system, the oven ensures every pellet—whether 2D or 3D—achieves uniform drying results, critical for consumer satisfaction and market acceptance.

Machine Features-Drying Oven

The 2D&3D Pellet Snack Drying Oven is designed with advanced engineering to meet the rigorous demands of modern snack production lines. Its multi-layer conveyor belt system enables continuous operation, maximizing production capacity while maintaining consistent quality. Each layer functions independently, allowing for flexible temperature control across different stages of the drying cycle.

|

Core Feature |

What It Does |

Why It Matters |

|

Multi-Layer Continuous Drying |

Dries pellets evenly across layers |

Ensures consistent snack quality |

|

Smart Temperature Control |

Adjusts heat for different recipes |

Saves energy, supports 2D & 3D pellets |

|

Hot Air Circulation |

Uniform airflow inside the oven |

Faster drying, stable results |

|

Hygienic Stainless Steel |

Food-grade durable build |

Easy to clean, long lifespan |

Technical Parameters – 2D&3D Pellet Snack Drying Oven

|

Parameter |

Specification |

Notes / Advantages |

|

Capacity |

200 kg/h – 1000+ kg/h |

Fits small to large-scale production |

|

Temperature Range |

50°C – 200°C |

Adjustable for 2D chips & 3D pellets |

|

Power Consumption |

Optimized with heat recovery system |

Lower energy use, consistent performance |

|

Drying Layers |

3 – 7 tiers |

Flexible residence time & uniform drying |

|

Design |

Multi-layer continuous baking |

Stable, reliable, industrial-grade |

|

Application |

2D snack chips, 3D extruded pellets |

Wide product adaptability |

Traditional Oven vs. 2D&3D Pellet Snack Drying Oven

|

Aspect |

Traditional Oven |

2D&3D Pellet Snack Drying Oven |

|

Capacity |

Limited, often <300 kg/h |

Scalable 200–1000+ kg/h for industrial use |

|

Temperature Control |

Basic, uneven heating |

Precise 50°C–200°C, adaptable to 2D & 3D snacks |

|

Energy Efficiency |

High energy loss, poor insulation |

Advanced heat recovery, reduced power consumption |

|

Drying Layers |

Usually single or double |

3–7 layers, flexible residence time |

|

Drying Uniformity |

Uneven, risk of under/over drying |

Consistent airflow, uniform product quality |

|

Operation |

Manual or semi-auto |

Fully automated, PLC & touch screen |

|

Maintenance |

Frequent, less durable |

Stainless steel, hygienic & long-lasting |

Applications-Continuous Drying System

In addition to traditional snack factories, the oven is increasingly adopted by export-oriented businesses seeking consistent product quality to meet international market standards. Its ability to handle different shapes and sizes of pellets ensures that every snack maintains the desired crispness, color, and shelf life—critical factors for consumer satisfaction.

The machine’s adaptability also makes it valuable in research and development facilities, where new snack formulations are tested before scaling up to full production. By providing precise control over temperature, airflow, and residence time, the 2D&3D Pellet Snack Drying Oven supports innovation while maintaining industrial reliability.

Conclusion

The 2D&3D Pellet Snack Drying Oven stands out as an essential machine for modern snack production, combining efficiency, precision, and durability. Its continuous multi-layer design ensures uniform drying for both 2D chips and 3D extruded pellets, while advanced temperature and airflow control guarantee consistent product quality. By integrating automation, energy-saving technology, and compliance with international safety standards, this oven supports high-volume industrial snack production while minimizing operational costs.

For snack manufacturers aiming to improve productivity, maintain product consistency, and expand into new markets, the 2D&3D Pellet Snack Drying Oven offers a reliable and versatile solution. From large-scale factories to specialized production lines, its adaptability and advanced features make it a strategic investment, enhancing both efficiency and product excellence in the competitive global snack industry.

Reference

The following are five authoritative foreign literature websites in the field of Industrial food machinery:

1. Food Engineering Magazine

Website: https://www.foodengineeringmag.com/

2.Food Processing Magazine

Website: https://www.foodprocessing.com/

3.Journal of Food Engineering

Website:https://www.journals.elsevier.com/journal-of-food-engineering

4. Food Manufacturing Magazine

Website:https://www.foodmanufacturing.com/

5. International Journal of Food Science & Technology

Website:https://onlinelibrary.wiley.com/

Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines