- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Processing> Take You to Understand the Corn Flake Making Machine

Take You to Understand the Corn Flake Making Machine

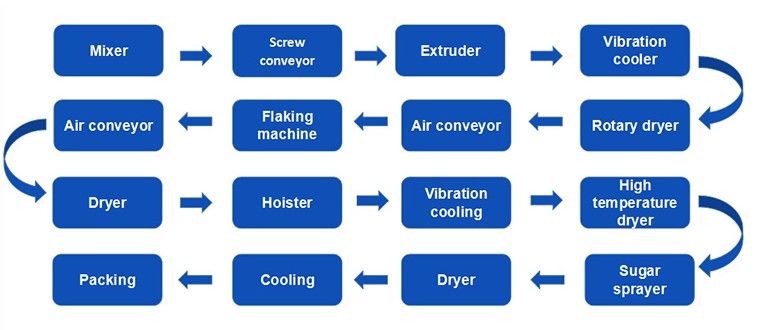

2021-10-11 11:50:55The corn flakes production line is composed of a mixing system, an extrusion system, a peeling system, a drying system, a seasoning system, a drying system and a packaging system.

I believe everyone knows that corn flakes is a very popular instant breakfast food. Its biggest feature is that it is convenient to eat and rich in nutrition. In the current fast-paced life, it is busy for life, especially for office workers. It is a very good choice for people, and it is also suitable for children and the elderly.

How are corn flakes made? What I want to introduce here is a special equipment for making corn flakes --- corn flakes making machine. As shown in the figure below, this is a new type of advanced equipment that solves the problems of sticky material on the drum, low tablet output, low molding rate, and poor taste. Reasonable equipment matching and achievable process control ensure the production of high-quality and delicious products. corn flake.

The corn flakes production line is composed of a mixing system, an extrusion system, a peeling system, a drying system, a seasoning system, a drying system and a packaging system. Through mixing, extrusion, baking, coating, drying and cooling, crisp corn flakes are obtained. All machines are made of stainless steel, and the food produced is high-quality and healthy, and meets food hygiene standards.

Features of corn flakes making machine:

1. The main extruder adopts frequency conversion speed regulation, which has a high degree of automation.

2. Forced lubrication system to ensure longer transmission life of the equipment.

3. The automatic temperature control system and self-cleaning function make it more convenient to use.

4. It has a wide range of applications and can produce products of different types and shapes.

5. The screws are made of stainless steel and special technology, which have the advantages of durability, high pressure resistance and long life.

Equipment list of corn flakes production line:

Mixer → screw conveyor → twin screw extruder → air conveyor → tablet press → air conveyor → dryer → elevator → hot air baking machine → seasoning machine → dryer → cooling machine → packaging machine

Main equipment functions:

1. Mixer: It mixes all kinds of raw materials, has a motor-driven stirring cage, an automatic water adding device and a pneumatic discharge valve, which mixes evenly, fast, and does not leak.

2. Twin-screw extruder: extrude the raw materials from the mold to produce corn flakes or other foods of the required shape and size, which consists of a feeding system, an extrusion system, a cutting system, and a heating system.

3, flake press: the puffed corn kernels into corn flakes, the motor drives the two pressure rollers rotate in the opposite direction, the speed of the pressure roller adjustable.

4、Dryer: puffed food with a certain amount of moisture, the drying process, the heating source can be electric, gas, steam and fuel.

5、Hot air baking machine: High-pressure blower ejects hot air to make tortilla chips instantly puffed and blistered. The product will be more crispy after hot air baking.

6、Seasoning machine: It is used to season the food to make the final product taste more delicious and better.

7、Packing machine: for the final packaging of the produced food and then for sale.

Corn Flakes Making Machine can use corn flour, wheat flour, rice flour or other grains as raw materials to produce corn flakes, nutritious oatmeal and various shapes of food. They are not only used as a breakfast mixed with milk or coffee, but also a casual snack. By changing the mold and production line, puffed foods of different shapes, such as rings, balls, slices, stars, letters, etc., can be made.

Corn Flakes Making Machine is developed and manufactured using advanced extrusion technology. Its technical performance and quality indicators have reached the international advanced level. It has been widely used, especially for small and medium-sized food processing plants. It is a very ideal equipment , Can bring considerable economic benefits.

Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines