- Shandong Loyal Industrial Co.,Ltd.

- Industrial Microwave Oven Food Extruder Machine Biscuit Making Machine

Home> Processing> The Models Of Dog Food Manufacturing Equipment And Differences

The Models Of Dog Food Manufacturing Equipment And Differences

2020-12-07 12:14:41The puffing effect is very good, the effect is particularly ideal. The taste is good, the control is convenient and timely. And it is not affected by the weather Under the influence of conditions, microwave equipment is available at any time without thermal inertia. The power level and transmission speed can be continuously and stably adjusted, and the development and development can be continued for 24 hours.

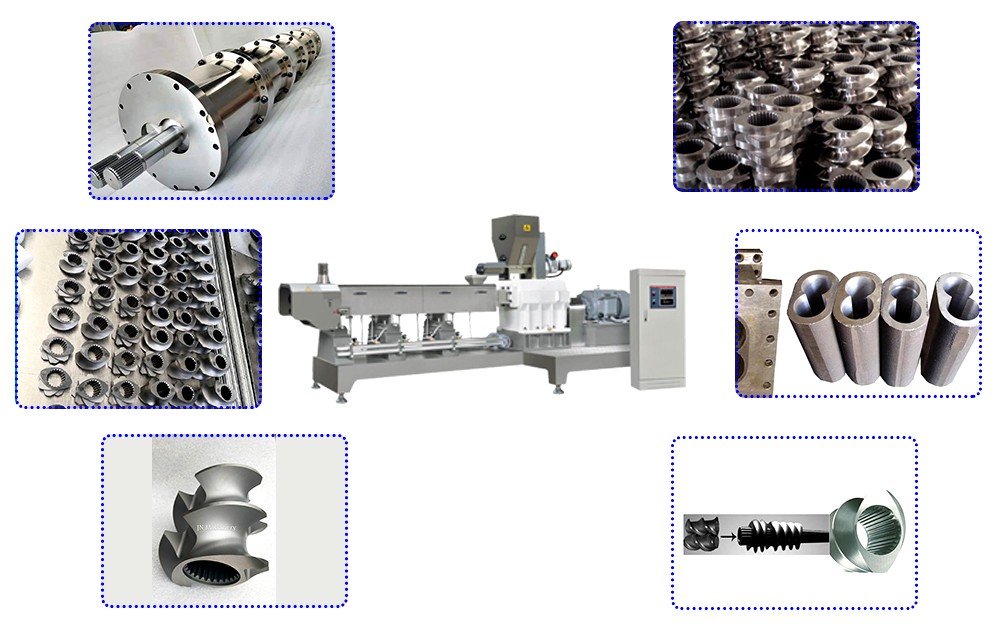

Extruded dog food machine equipment production line, specializing in the production of various models and specifications of puffed dog food. For small and medium-sized farms and pet farms. The output of our dog food machinery equipment is 100-2000 kg per hour, divided into different machine configurations, the list is as follows:

1. LY65 series dog food machine

Output: 100-150 kg per hour

Actual power consumption: 70-90 degrees per hour

Equipment placement, production and use of plant area: 40-50 square meters

Manual: 2-3 people operation

Equipment configuration: mixer-automatic feeder-extruder-conveyor-dryer-automatic conveyor-seasoning machine-fuel injection machine-cooling conveyor

2. LY70 series dog feed equipment

Output: 200-250 kg per hour

Actual power consumption: 90-110 degrees per hour

Equipment placement, production and use of plant area: 50-60 square meters

Manual: 2-3 people operation

Equipment configuration: mixer-automatic feeder-extruder-conveyor-dryer-automatic conveyor-seasoning machine-fuel injection machine-cooling conveyor

3. LY85 series dog food making production line

Output: 400-550 kg per hour

Actual power consumption: 190-210 degrees per hour

Equipment placement, production and use plant area: 90-120 square meters

Manual: 2-3 people operation

Equipment configuration: mixer-automatic feeder-extruder-conveyor-dryer-automatic conveyor-seasoning machine-fuel injection machine-cooling conveyor

4. LY95 series dog food making procession line

Output: 800-1200 kg per hour

Actual power consumption: 110-130 degrees per hour

Steam consumption: 1.5-2 tons of steam boilers, customer-provided

Equipment placement, production and use of plant area: 150-200 square meters

Manual: 2-3 people operation

Compared with the conventional method, it has the bright spot of low temperature and rapid speed. And it can maintain the original color, aroma and taste of pet food without destroying the nutrients. The puffing effect is very good, the effect is particularly ideal. The taste is good, the control is convenient and timely. And it is not affected by the weather Under the influence of conditions, microwave equipment is available at any time without thermal inertia. The power level and transmission speed can be continuously and stably adjusted, and the development and development can be continued for 24 hours.

1. Compared with the cost, the slab conveyor supports and transports materials by using the supporting members connected to the traction chain, just like the flat plate or the scale of various types of structures and forms;

2. Large carrying capacity, capable of transporting dozens of tons, especially suitable for transporting heavy materials;

3. The conveying length can reach more than 120 meters, which is stable and reliable, suitable for the assembly line of single-weight products;

4. The equipment has a firm and stable structure and can be used in harsh environments.

5. Various accessories or fixtures can be installed on the chain plate. The pet food conveyor has a flexible conveyor line that can transport, climb and turn horizontally.

The safety and sanitation of electric rollers used in pet food manufacturing lines is accompanied by the popularity of cycloidal needle wheel electric rollers in the pet food transportation industry. Our pet food production environment is safer and sanitary. Products can be automatically classified into types by packaging, which reduces the chain ratio. Manual, improve the power level. In the pet food research and development production line using the cycloidal pinwheel electric roller. Because of the fully sealed structure, impurities are not easy to enter. And the related items will not leak out, and the cleaning is quite convenient. At the same time, the external material is stainless steel or some pet food grade engineering materials, which cannot cause any pollution to pet food. However, the motor model used in the past has relatively large drawbacks. The traditional motor surface requires a large number of heat sinks and fans. In addition, the fan needs the same slot, which makes it easy for food residues and bacteria to enter. The cycloidal pinwheel electric roller is mainly driven by an installed motor. And it provides the usual power for the movement of goods. Whether it is the check-in counter at the airport, the cash register at the supermarket, the warehouse or the express delivery.

Pet Food Production Line

Pet Food Production Line Dog Treat Biscuit Making Machine

Dog Treat Biscuit Making Machine Instant Pasta Production Line

Instant Pasta Production Line 150Kw Fully Automatic Industrial Continuous Microwave Shrimp Drying Machine

150Kw Fully Automatic Industrial Continuous Microwave Shrimp Drying Machine Continuous Tunnel Honeysuckle Flower Drying Dehydrator Machine Tunnel Microwave Baking And Sterilizing Equipment

Continuous Tunnel Honeysuckle Flower Drying Dehydrator Machine Tunnel Microwave Baking And Sterilizing Equipment Automatic Microwave Frozen Meat Beef Thawing Machine

Automatic Microwave Frozen Meat Beef Thawing Machine