- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Company News> Wafer Biscuit Production Line

Wafer Biscuit Production Line

2023-03-15 09:06:46Wafer making machines is designed and manufactured according to the facts of domestic biscuit manufacturing industry and absorbing the most well-known wafer production lines of many overseas manufactures. The wafer biscuits making machine is used to make a wide range of dimensions wafer biscuits with different capacities for customers’ options. We provide high quality with the program easy to operation. The biscuit plant equipment can be combined and displayed according to the customer’s request.The whole production line fully automatic and reasonable design, can saves labor and space for customers,and makes high-quality wafers at low cost.The wafer production line adopts advanced German technology and isimproved by LOYAL engineers. From batter mixing to bags, box packaging is completed at one time.The fully automatic wafer production line can customize different wafer templates according to customer re-quirements, and produce various high-quality wafers with different patterns, shapes, depths, and sizes.

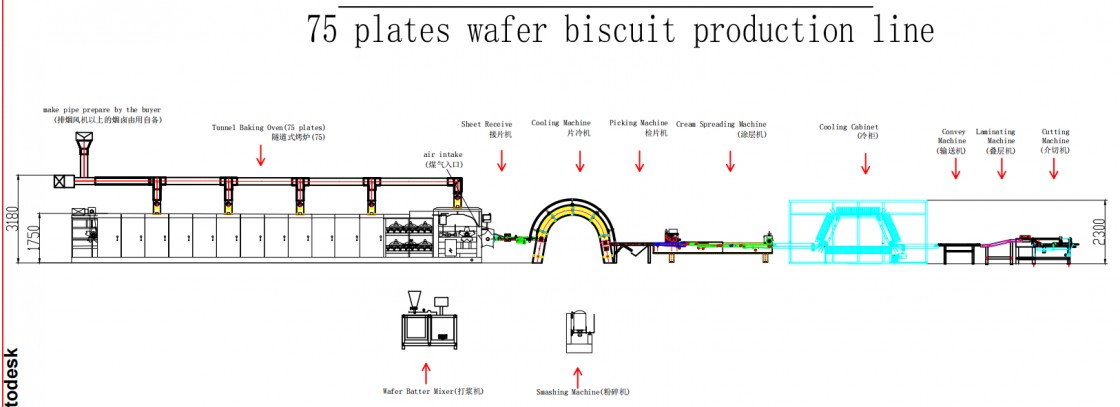

Flow Chart Of Wafer Biscuit Production Line

Parameter Of Wafer Making Machines

|

Model |

27 |

33 |

39 |

45 |

51 |

65 |

75 |

100 |

|

Oven Length (Mm) |

6000 |

7150 |

8300 |

9450 |

10600 |

13300 |

15000 |

20000 |

|

Production Line Length (Mm) |

22000 |

23150 |

24300 |

25450 |

26600 |

29300 |

38500 |

44350 |

|

Oven Power (Kw) |

5.52 |

5.52 |

5.52 |

5.52 |

5.52 |

5.52 |

8.12 |

24 |

|

Consumption Of Liquefied Gas (Kg/h) |

13 |

15 |

19 |

23 |

27 |

32 |

45 |

50 |

|

Natural Gas Consumption (m³/h) |

16 |

21 |

25 |

30 |

35 |

45 |

58 |

67 |

|

Electric Heating Power (Kw) |

14 |

17 |

20 |

23 |

26 |

33 |

45 |

78.8 |

|

Output (Kg/h) |

90 |

110 |

130 |

150 |

170 |

215 |

300 |

780 |

What’s The Function Of Wafer Biscuit Production Line

- Mixing And Preparation: The first step in the production process is the preparation of the batter for the wafer biscuit. The batter is usually a mixture of flour, sugar, eggs, oil, and water. These ingredients are mixed together in a large mixing bowl to form a smooth batter.

- Baking: The batter is then poured onto a baking plate and placed in an oven to bake. The baking process usually takes a few minutes, and the temperature is carefully controlled to ensure that the wafer biscuits are evenly baked.

- Cooling: Once the wafer biscuits are baked, they are removed from the oven and allowed to cool. This is done to prevent the biscuits from breaking or cracking during the subsequent stages of production.

- Cream Filling: After the biscuits have cooled, they are placed on a conveyor belt, and a cream filling is piped onto one side of the biscuits. The cream filling is usually made of a mixture of sugar, milk, and cream, and it gives the wafer biscuit its characteristic taste and texture.

- Cutting: The wafer biscuits are then cut into the desired shape and size using a cutting machine. This is done to ensure that the biscuits are uniform in size and shape, which is important for packaging and presentation.

- Packaging: The final step in the production process is the packaging of the wafer biscuits. The biscuits are usually placed in individual packets or wrapped in foil, which helps to keep them fresh and crispy.

Overall, a wafer biscuit production line is a complex process that requires careful attention to detail at every stage. The end result is a delicious and crispy wafer biscuit that is enjoyed by people all over the world.

Advantages Of Wafer Making Machines

|

1 |

Sus 304 material for health and safety standards |

|

2 |

Automatic control |

|

3 |

High quality and price competitive |

|

4 |

Ce and iso certification available |

|

5 |

Separate cooling system to ensure the air-dried |

|

6 |

Visible safety covers |

|

7 |

Self-clean up after ending production |

|

8 |

Easy installation and maintenance |

|

9 |

Over 20 engineers with many overseas installation experiences |

|

10 |

Formula available for each customer |

|

11 |

Quick lead time |

|

12 |

Technology supporting online within 24 hours |

|

13 |

Annual maintenance |

Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines