- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Processing> What Are The Important Effects Of Extruder Of Pet Feed Production Equipment On Pet Feed?

What Are The Important Effects Of Extruder Of Pet Feed Production Equipment On Pet Feed?

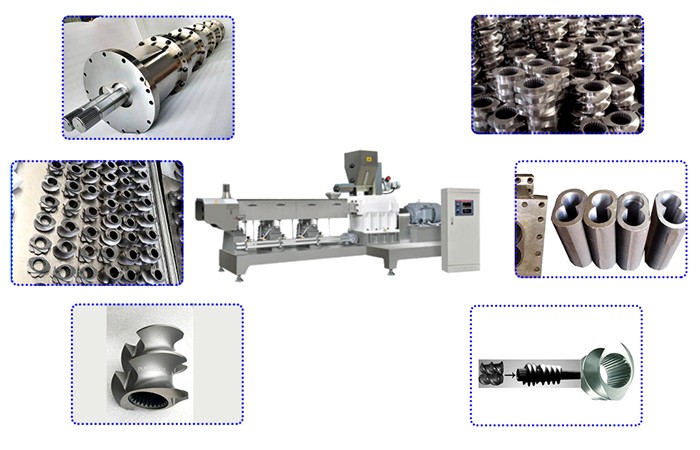

2021-03-17 11:17:35As a leading manufacturer of pet feed pellet machine processing line, we have advanced processing equipment and modern mould. The pet food extruder can manufacturer the food with novel various shape, particular tastes and scientific nutrition for lovely pets.

As a leading manufacturer of pet feed pellet machine processing line, we have advanced processing equipment and modern mould. The pet food extruder can manufacturer the food with novel various shape, particular tastes and scientific nutrition for lovely pets. Our machines enjoy excellent sales by its high outputs and simple and easily be operated which can help you save manufacture space and manufacture cast.

In order to increase the protein and other nutrients for our pet, automatic dry dog pet food machine processing line use meat powder, grains, beans and vegetables as raw materials to produce pet food with new shape, unique taste to let them live healthier.

In order to increase the protein and other nutrients for our pet, automatic dry dog pet food machine processing line use meat powder, grains, beans and vegetables as raw materials to produce pet food with new shape, unique taste to let them live healthier.

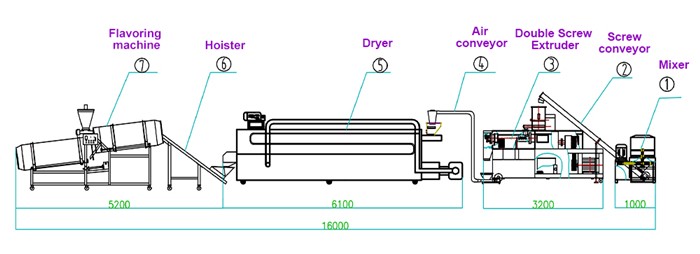

Flow chart of automatic pet food making machine processing :

Mixer- Screw Conveyor-Double Screw Extruder-Air Conveyor-Dryer-Hoiser-Flavoring Machine-

The extrusion process is a process of forming pet feed materials. During the molding process, water is added in the form of steam to gelatinize the pet feed raw material starch, and the temperature is raised to 100 degrees Celsius-180 degrees Celsius. Due to the high pressure before extrusion, the pressure is released instantaneously during extrusion, and the moment the water rushes out of the pellets, the pet feed rapidly expands and foams and the water evaporates. Therefore, pet feeds that have undergone the extruded manufacturing process generally have good absorption and high nutritional value.

The extrusion process is a process of forming pet feed materials. During the molding process, water is added in the form of steam to gelatinize the pet feed raw material starch, and the temperature is raised to 100 degrees Celsius-180 degrees Celsius. Due to the high pressure before extrusion, the pressure is released instantaneously during extrusion, and the moment the water rushes out of the pellets, the pet feed rapidly expands and foams and the water evaporates. Therefore, pet feeds that have undergone the extruded manufacturing process generally have good absorption and high nutritional value.

What are the important effects of the extruder of pet feed production equipment on pet feed?

1. Puffing equipment improves the palatability of pet feed. The pet feed becomes crispy after being puffed, and the pet has a better taste during the process of biting and swallowing, which is also conducive to the cleaning of the pet's oral teeth;

2. Puffing can change and improve the nutritional value of pet feed. Many nutrients need to be matured and puffed before they can become nutritionally valuable. Otherwise, not only will it not bring nutrition to the pet, but it will cause diarrhea, vomiting and other unindications;

3. Puffing equipment can improve the digestion and absorption rate of pet feed by pets. The extruded pet feed can be absorbed more and more perfectly by pets;

4. Through the process of puffing to make pellets, the shape and structure of pet feed are changed;

5. Pet feed production equipment can change the content of different nutritional indicators of pet feed. For example, reducing moisture can increase the shelf life of pet feed;

6. Change the density of pet feed. Extrusion granulation and expansion can also increase the bulk density of pet feed, which is convenient for purchase and transportation;

7. The puffing process is also a high temperature and high pressure process, which can kill various molds and other harmful substances and improve the sanitation of pet feed.

In summary, the expansion of pet feed production equipment plays a vital role in pet feed, so pet feed extruded equipment is an important joint in pet feed production line.

Pet Food Production Line

Pet Food Production Line Dog Treat Biscuit Making Machine

Dog Treat Biscuit Making Machine Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines