- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Processing> What is the cereal production line?

What is the cereal production line?

2021-10-20 15:39:01The above is a related introduction to the cereal production line, mainly talking about the characteristics, production process and application of the Cereal Production Line.

Breakfast cereal is a kind of instant food with rich nutrition, convenient eating and natural quality, such as corn flakes, oatmeal, red date flakes, whole cereal flakes, custard stars, etc. all belong to this category of foods. Breakfast cereals are crispy and have an excellent taste. They are suitable for people of all ages. It is a perfect match to eat with milk in the morning.

How are breakfast cereals produced? The next thing to talk about is the Cereal Production Line, which is an equipment specially designed to produce a variety of breakfast cereals. A twin-screw extruder or a single-screw extruder is used to process the cereal flakes, and the resulting breakfast cereals are excellent in substance. Delicious, it is a very popular food in families.

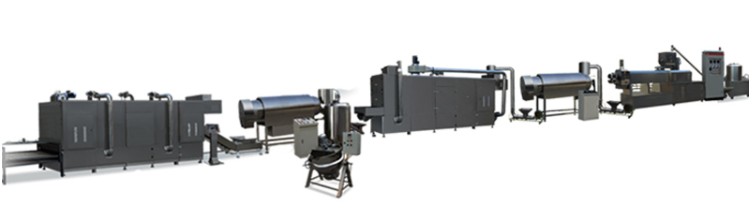

As shown in the figure, this is the breakfast cereal production line. It can be seen that the production line has a beautiful appearance, stylish atmosphere, and its performance and quality are very reliable, and it has many advantages.

Features of cereal breakfast production line:

1. Ingenious design, reasonable structure and simple operation.

2. Durable stainless steel and special technology, long service life.

3. Automatic temperature control system and high self-cleaning ability.

4. Vibration conveying, it is not easy to stick, the material is heated evenly, and it is easy to dry.

5. The products produced are safe and healthy, with high quality and perfect craftsmanship.

Production line process flow:

Ingredients---mixing---conditioning---extrusion---tabletting---drying---baking---spraying---drying---cooling---packaging

Production line composition system:

Mixing system---Extrusion system---Peeling system---Drying system---Sugar spraying system---Drying system---Cooling system---Packing system

1. Batching system: After the batching system is completed, if there are multiple hosts, an automatic powder feeding system can be selected.

2. Extrusion system: It uses multiple types of hosts with high degree of automation. The equipment can realize the one-key start of the host, save data in real time, monitor in real time, and automatically alarm.

3. Pre-drying system: Generally, there are small-scale vibrating fluidized bed, drum drying, and eight-layer vibration drying can be selected.

4. Sugar spray system: spray syrup on the surface of the material to adjust the taste of the product. It is divided into two main parts: the drum and the slurry tank. In order to improve the fluidity and adhesion of the syrup, the drum rotates continuously and is equipped with a heating structure. A heat preservation device is also added to the outside of the drum.

5. Drying system: It has a forced hot air circulation system to increase the efficiency of the thermal process. A variety of heat sources can be used, such as medium, electricity, gas, fuel oil, steam, etc. It has a forced hot air circulation system to increase the efficiency of the thermal process.

6. Packaging system: automatically complete the process of feeding, metering, filling and bag making, date printing, inflation (exhaust) and output. The measurement accuracy is high, the efficiency is high, and the material is not easily broken.

Final product category:

Corn flakes, whole wheat flakes, breakfast cereals, cereals, ready-to-eat cereals, crispy gule, fruit oatmeal, custard stars, honey rings, high-fiber whole wheat fiber, whole-cereal dietary fiber oatmeal, etc.

The cereal production line can use corn, wheat, oats, rice, barley, rye, buckwheat or barley as raw materials to make delicious breakfast cereals for sale. After mixing, squeezing, pressing, drying, baking, coating and cooling, different types of breakfast cereals are obtained. The production line can produce cereals of various shapes, such as rings, balls, curls, stars, wheels, etc.

The above is a related introduction to the cereal production line, mainly talking about the characteristics, production process and application of the Cereal Production Line. I believe you have a certain understanding of this after reading it, and I hope it will be helpful to you.

Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines