- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Processing> Why Choose The Twin Screw Puffed Food Extruder

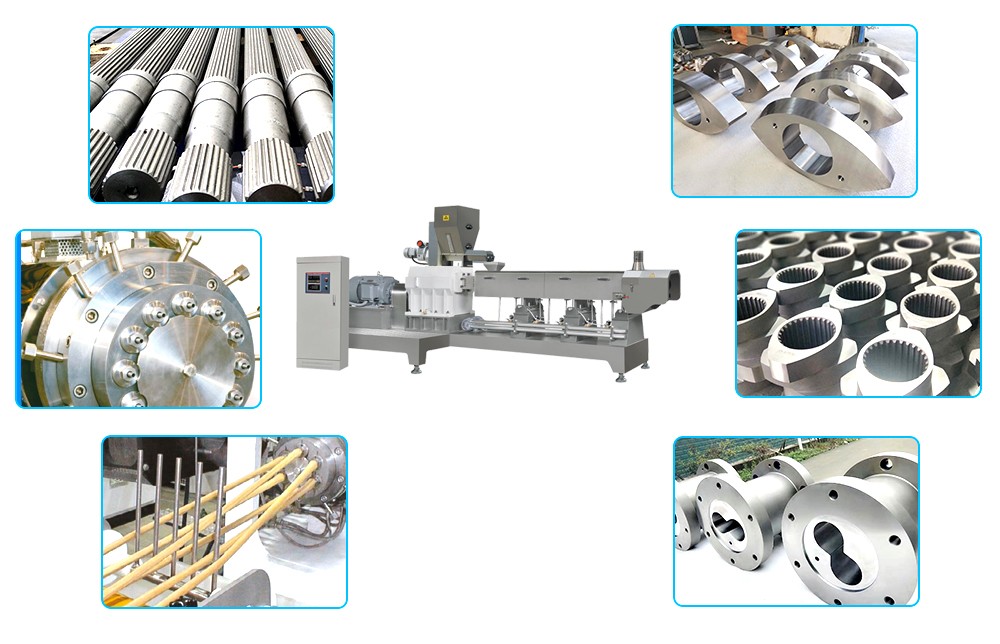

Why Choose The Twin Screw Puffed Food Extruder

2021-08-12 18:48:07Automatic puffed food extruder processing means: the food material is placed under the high temperature and high pressure state of the extruder, and then suddenly returned to the normal temperature and pressure state, so that the internal structure and properties of the material are changed.

Introduction of the twin screw extruder includes the impact of the micro-structure and physical and chemical properties of the raw materials after extrusion, the performance of the extruder and the characteristics of the raw materials themselves on product quality, etc.

Automatic puffed food extruder processing means: the food material is placed under the high temperature and high pressure state of the extruder, and then suddenly returned to the normal temperature and pressure state, so that the internal structure and properties of the material are changed. Introduction of materials and ingredients of puffed snack food processing: These materials are usually made of cereal raw materials (such as rice, beans, wheat, glutinous rice, sorghum, corn, etc.), mixed with water and ingredients containing fat, protein, and trace elements.

Introduction of materials and ingredients of puffed snack food processing: These materials are usually made of cereal raw materials (such as rice, beans, wheat, glutinous rice, sorghum, corn, etc.), mixed with water and ingredients containing fat, protein, and trace elements.

Industrial puffed food extruder processing method: In the extrusion processing process, the material is pushed forward and extruded by the driving force of the twin screw extruder. The material is subjected to mixing, stirring, friction and high shear force to disintegrate the starch granules. At the same time, the machine cavity The internal temperature and pressure increase (the temperature can reach 100-200℃, and the pressure can reach more than 1MPa), and then, it is extruded from a certain shape of the die hole, and the high temperature and high pressure suddenly drops to room temperature and pressure. The free moisture contained in the raw material , Under this pressure difference, it vaporizes sharply, and the volume of water can expand about 2000 times. At the moment of expansion, the structure of the grain changes. It converts raw starch (β-starch) into mature starch (α-starch), and at the same time, it turns the product into a lamellar and loose sponge. The volume of the grain expands several times.

Wide range applications of the twin screw extruder: various puffed and fortified foods can be processed by extrusion technology, suitable for snack foods, instant grain foods, convenience foods, dairy products, meat products, aquatic products, condiments, sugar products, chocolate products, etc. In the field of food production, the shape of the product can be changed by simply changing the mold, and products with different shapes and patterns can be produced. In addition, it can also be used to process the raw materials of brewed food to increase the yield.

Wide range applications of the twin screw extruder: various puffed and fortified foods can be processed by extrusion technology, suitable for snack foods, instant grain foods, convenience foods, dairy products, meat products, aquatic products, condiments, sugar products, chocolate products, etc. In the field of food production, the shape of the product can be changed by simply changing the mold, and products with different shapes and patterns can be produced. In addition, it can also be used to process the raw materials of brewed food to increase the yield.

Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines