- Shandong Loyal Industrial Co.,Ltd.

- Industrial Microwave Oven Food Extruder Machine Biscuit Making Machine

Home> Processing> Artificial Rice Making Process Optimization And Structure Characterization

Artificial Rice Making Process Optimization And Structure Characterization

2020-07-05 10:13:39Rice as the most important staple food in people's daily life, is rich in nutrients and can provide the body with the energy it needs every day. However, rice has a low protein content and an unreasonable proportion of amino acids, so it needs to be strengthened. The rice extruder extrusion method is a high-temperature short-term treatment process, artificial rice procedure is a high-tech technology that integrates mixing, stirring, crushing, heating, sterilization and molding. Under the action of high temperature, high pressure and high shear force during the extrusion rice processing, the macromolecular substances such as starch and protein in the rice are cut into small molecular substances. After adding various trace elements, they are cooked by the extruder to make a gold crystal clear and transparent. The properties of the rice grains are vacuum-packed after drying. When they are eaten, they can be steamed directly or added with rice in a ratio of 2:8. The steamed rice and corn taste sweet, the rice grains are not easy to loosen, and the product with very good taste is used.

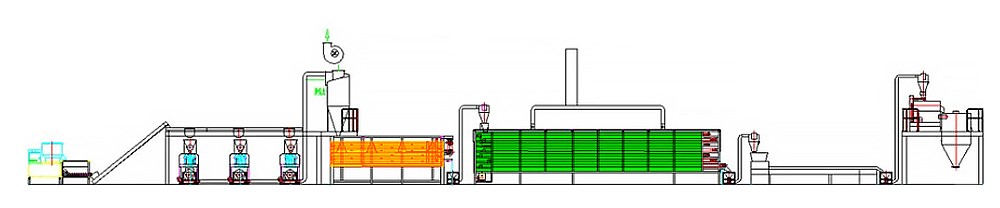

Rice processing flow chart

Broken rice→crushed→screened→mixed→tempered→extruded→aged→dried→cooled→packed

The crushed rice is crushed, passed through a 100 mesh sieve, mixed with calcium fortifier, and then adjusted by a certain quality of water content through steam and water, and then enters the extruder for re-granulation. Study the moisture content, barrel temperature and screw speed during the extrusion process on the hardness, elasticity and adhesion of calcium-reinforced rice.

The crushed rice is crushed, passed through a 100 mesh sieve, mixed with calcium fortifier, and then adjusted by a certain quality of water content through steam and water, and then enters the extruder for re-granulation. Study the moisture content, barrel temperature and screw speed during the extrusion process on the hardness, elasticity and adhesion of calcium-reinforced rice.

The effect of sex and chewability, in order to get better calcium-fortified rice. Then the product fortified rice is aged at 35 ℃ and 70% relative humidity for about 3 hours. The aged rice is sent to a hot air drying oven, dried at 45 ℃ for 40 min, and cooled and packaged.

Effect of barrel temperature, screw speed and water content on hardness

As shown in Figure 1, the influence of barrel temperature and water content on the hardness of artifical rice/calcium-reinforced rice is extremely significant, and the influence of screw speed and water content on the hardness of artifical rice/calcium-reinforced rice is more significant. When the screw speed is constant, the hardness of artifical rice/calcium-reinforced rice increases first and then decreases gradually as the temperature of the barrel increases, and the hardness increases first and then decreases as the moisture content increases. This is mainly because when the temperature is low, the squeezing effect of the material is insufficient, and when the temperature is too high, the degree of water evaporation in the rice is high, and the expansion rate of the rice is high, so the hardness is low; when the barrel temperature is constant, calcium The hardness of the strengthened rice increases first and then decreases with the increase of the screw speed and water content. When the screw speed is low, the material stays in the barrel for a longer time and the heating time is longer, so the hardness is lower. When the screw speed When it is too large, the residence time of the material is short, and the extrusion effect is insufficient, resulting in a decrease in hardness.

Note: When examining the effect of two factors on the indicator, the third factor is fixed at the zero level, the same as below.

Fig.1 Effect of barrel temperature, screw speed and water content on hardness

Effects of Barrel Temperature, Screw Rotation Speed and Mass Water Content on the Elasticity of Artifical Rice

In Figure 2, the effects of screw speed and water content, barrel temperature and screw speed on the elasticity of calcium-reinforced rice are extremely significant. When the barrel temperature is constant, the elasticity of calcium-reinforced rice increases with the increase in screw speed Slightly increased, and gradually increased with increasing water content. This is because the increase in the water content increases the expansion rate of the rice and increases its elasticity; when the water content is constant, as the barrel temperature and screw speed increase, the material is subjected to high temperature and high shear forces. Higher degree of gelatinization and increased elasticity

Fig. 2 Effect of barrel temperature, screw speed and water content on springness

The effect of barrel temperature, screw speed and mass water content on the adhesion of artifical rice

shown in Figure 3. The effect of barrel temperature and screw speed on the adhesion of artifical rice/calcium-reinforced rice is extremely significant. The barrel temperature and water content, screw The effects of rotation speed and water content on the adhesion of artifical rice/calcium-reinforced rice are more significant. When the water content is constant, the adhesion of artifical rice/calcium-reinforced rice decreases as the screw speed increases. This is mainly because when the screw speed is high, the material stays in the extruder for a short time, and the temperature in the barrel is high, so that the rice is in a molten state, so the adhesion is reduced; when the screw speed is constant, the The high barrel temperature increases the gelatinization degree of rice and reduces the adhesion; and when the barrel temperature is constant and the moisture content is low, the material in the barrel is dry, which is not conducive to the forward conveying of the screw. The rice is in the barrel The longer the internal residence time is, the higher the degree of gelatinization; and when the screw speed is increased, the rice is subjected to a strong shear force, which reduces the adhesion.

Fig.3 Effect of barrel temperature, screw speed and water content on adhesiveness

The effect of barrel temperature, screw speed and mass water content on the chewability of artifical rice

In Figure 4. The influence of barrel temperature and water content on the chewability of artifical rice/calcium-fortified rice is extremely significant. Barrel temperature and screw speed on calcium The effect of strengthening the chewability of rice is more significant. When the screw speed is constant, the chewability of artifical rice/calcium-enhanced rice tends to increase first and then decrease with the increase of water content, and gradually increase and then gradually decrease as the barrel temperature increases. This is because when the barrel temperature and moisture content are low, the material is dry, the pressure at the die is high, and it is not easy to pass , so the rice stays in the barrel for a long time, the starch structure is destroyed, and the chewability is more Low; when the barrel temperature and water content are large, the material is in a fluid state, the pressure at the die is small, and it can pass smoothly, and the chewability is improved; while when the temperature continues to rise, the rice is in a molten state and the chewability is reduced; When the water content is constant, the barrel temperature and screw speed are lower, the degree of rice gelatinization is lower, the structure is loose, and the chewability is lower. When the barrel temperature and screw speed are too high, the rice is subjected to high temperature and high shear, which appears With a slight puffing phenomenon, the structure begins to loosen, so the chewability decreases.

Fig.4 Effect of barrel temperature, screw speed and water content on chewiness

The rice is reorganized by extrusion. In the experiment, the response surface method was used to study the influence of extrusion process parameters on the texture of calcium-reinforced rice. The best process parameters were obtained: barrel temperature 100 ℃, screw speed 85 r/min, mass water content 20.0%. Under the best technological conditions, the calcium-reinforced rice has a hardness of 13.38 N, an elasticity of 0.67 mm, an adhesiveness of 0.64 mJ, and a chewability of 851.51 mJ. Its texture characteristics are similar to those of japonica rice, and its calcium content is 108.2 mg/(100 g). After the extrusion treatment, the crystallinity of the strengthened rice is significantly reduced, showing an irregular shape. The gelatinization temperature and viscosity of rice are reduced, and the stability is better. Adding it to japonica rice in a certain proportion will not only make full use of broken rice, but also increase the body's intake of calcium.

Japanese panko bread crumbs making machine

Japanese panko bread crumbs making machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Instant Pasta Production Line

Instant Pasta Production Line