- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Processing> Composition And Daily Maintenance Of Bugles Making Equipment Processing

Composition And Daily Maintenance Of Bugles Making Equipment Processing

2020-09-16 16:12:20The puffed bugles production equipment is an advanced puffed food equipment developed by the company according to the needs of the domestic and foreign markets. Its operating performance, product quality, and process taste have reached the advanced level of the same industry.

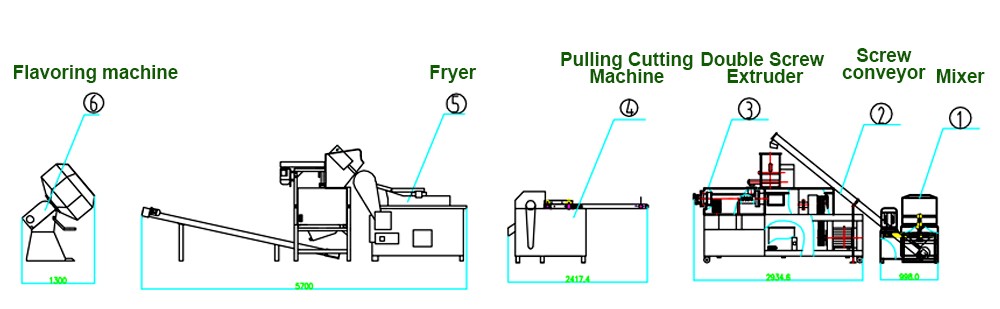

Sharp corner brittle production equipment technological process:

Raw Material Preparation → Mixing → Conveying → Extrusion → Cutting Machine → Frying → Seasoning → Packaging

The puffed bugles production equipment is an advanced puffed food equipment developed by the company according to the needs of the domestic and foreign markets. Its operating performance, product quality, and process taste have reached the advanced level of the same industry. The automatic bugles production line is simple to operate, easy to learn and understand. It is an ideal choice for manufacturers engaged in the rice cracker salad. It can produce various shapes of rice cracker salad. Its taste is crispy, oily but not greasy, and leaves a lingering fragrance after eating. The characteristics of promoting digestion in the intestinal tract, so that the majority of consumers can eat after meals.

Bugles Making Process Composition:

1. Powder mixing machine: Choose different types of powder mixing machine according to the output of the production line.

2. Feeding machine: use the motor as the power screw conveyor to ensure convenient and fast feeding.

3. Extruder: Choose different types of extruder according to the output of the industrial bugles production line. The output can be selected according to the actual production. Corn meal, cereal meal, bone meal, meat meal, etc. can be used as raw materials. The specific product shape can replace the mold.

4. Cutting machine: Bugles cutting machine, the size of the wonderful bugles can be adjusted according to customer requirements.

5. Fryer: It can be configured according to customer requirements, and the oil throwing type is more economical.

6. Seasoning line: There are octagonal tube, single drum, double drum seasoning line, according to the output and product nature.

Professional Service:

|

1 |

Provide various basic formulas; |

|

2 |

A variety of shapes are available; |

|

3 |

Free installation and debugging; |

|

4 |

Responsible for training personnel; |

|

5 |

One year free warranty. |

|

6 |

The production line can be turned around according to the size of the customer's plant. |

|

7 |

The customer can provide the size of the plant, and the technician will give the best equipment plan for free. |

Fried Bugle Chips Snack Machine

Fried Bugle Chips Snack Machine Fried Dough Snack Machine

Fried Dough Snack Machine Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines