- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Processing> How To Debug And Maintain The Extruder?

How To Debug And Maintain The Extruder?

2020-09-16 10:25:38Are Loyal's friends also preparing to start work? Before the start of construction, we must carry out simple debugging and maintenance before starting the equipment!

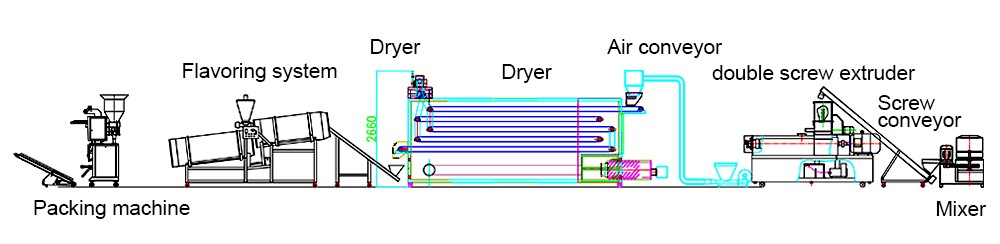

Twin screw extruder is one of our common puffing equipment. Before using the screw extruder, it must be debugged to ensure its smooth work. What kind of work should be done for debugging? The following is introduced by our professionals:

1. Before use, first remove the die head of the double screw extruder, apply some cooking oil on the inner thread of the die head and the screw head, then tighten the die head, tighten the front flange, and mix the rear flange evenly .

2. After turning on the machine, let it idle for half a minute. If there is no abnormal sound, you can put the raw materials into the machine. When the sprayed product can slowly form, you can add the raw materials in batches and gradually increase the input amount.

3. If the twin screw extruder machine returns during operation, it means that the blanking is too urgent and the temperature of the die head does not reach 120 degrees. At this time, the blanking should be stopped, and the die head should be idly transferred to the die head to spray new products before blanking. If the pattern of the die head has hard non-formed products. It means that the temperature inside the machine is low. And the blanking should be stopped and idling for a while. And then blanking after the normal product is ejected.

In addition, how should we maintain the twin extruder machine after use? First of all, because the wearing parts near the discharge port wear relatively fast, the wearing parts near the feed port are less worn, so when replacing the wearing parts. The discharge end starts to be replaced sequentially. It is not suitable to replace multiple parts at once. Secondly, the extruded raw materials should be cleaned to prevent metal and other foreign objects from entering the machine to damage the parts. Check the quality of the extruder at any time and pay attention to replacing the wearing parts.

Twin Screw Food Extruder Machine

Twin Screw Food Extruder Machine Single Screw Extruder Food Processing Machine

Single Screw Extruder Food Processing Machine Pet Food Extruder Machine

Pet Food Extruder Machine Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines