- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Company News> Crispy Chips/ Bugles /Sticks /Sala Processing Line

Crispy Chips/ Bugles /Sticks /Sala Processing Line

2023-02-24 09:47:171.Introduction Of Crispy Chips/ Bugles /Sticks /Sala Processing Line

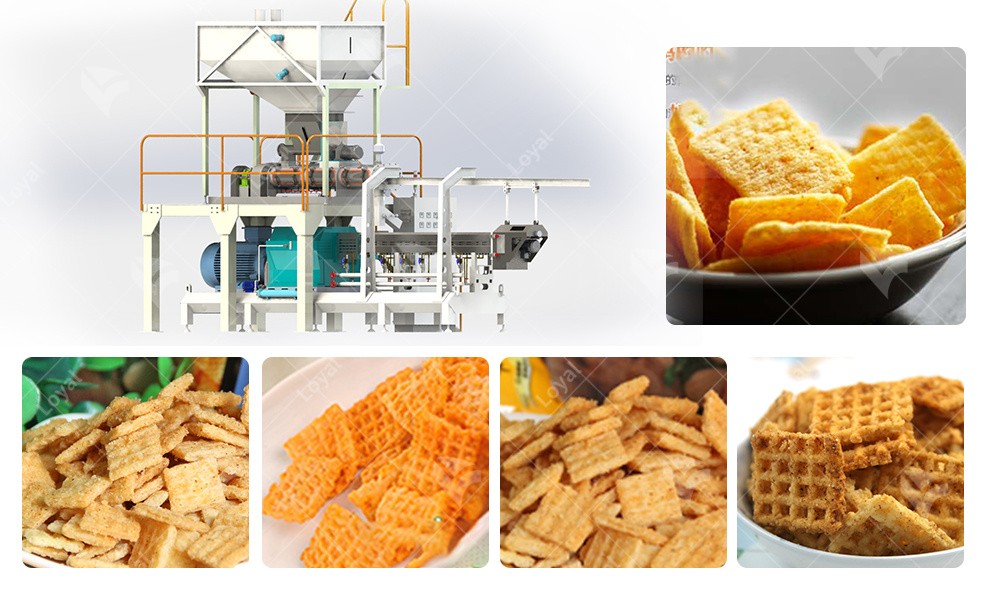

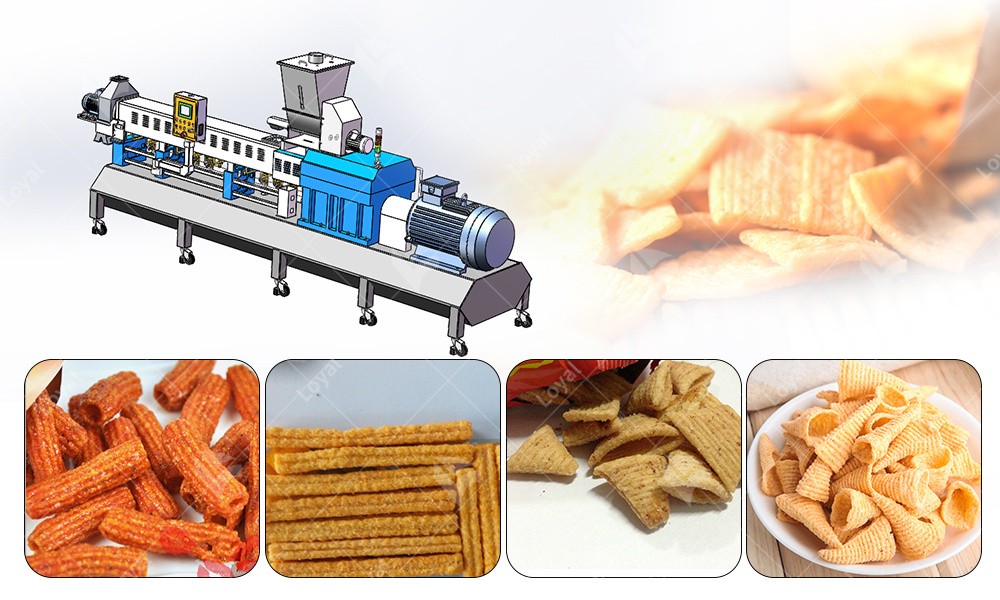

Salad chips/ bugles/ sticks processing line adopts corn powder, corn starch, potato starch, cassava starch, wheat flour and other high starch content materials for production.

Salad chips/ bugles/ sticks processing line can be used for producing many kinds pellet chips snacks food, such as Bugles, Screws, Shells, 2D chips, 3D pellets, Cakes, Tortilla, and Doritos, and so on. According to different product, it need different cutter.

2. Raw Materials For The Fried Crispy Chips Snacks Making

Corn flour, rice flour, wheat flour,potato flour and other grain flour etc

3.Flow Chart Of Crispy Chips/ Bugles /Sticks /Sala Processing Line

Mixer--Screw Conveyor--Twin-screw Extruder -- Cutter-- Hoister -- Continuous Fryer --Deoiling Machine--Flavoring Line

4.Introduction Of Each Equipment At The Fried Chips Snack Production Line

|

Equipoment Name |

Function |

|

Mixer |

Mix the material together |

|

Screw Conveyor |

Conveying the material into the extruder |

|

Twin-Screw Extruder |

Extruding & puffing&shaping snacks |

|

Cutting&Shaping Machine |

Cut &Shape the snacks |

|

Food Grade Pvc Hoister |

Conveying the snack chips to frying machine |

|

Continuous Fryer |

Frying the snack chips |

|

Deoiling Machine |

Remove the extra oil on the snack |

|

Flavoring Line |

Spraying oil and seasoing powder on the snacks |

|

Whole Line Length |

20-25m |

|

Voltage And Frequency |

we can make it according to customers' local voltage according to different countries. |

5.Advantages Of Crispy Chips/ Bugles /Sticks /Sala Processing Line

|

1 |

Alloy (38CrMoAL) screw made by nitriding process, high strength and wear-resting. Self-cleaning ability, no need to discharge or clean the barrel and screw when roasting or replacing of materials. |

|

2 |

Adopting speed-adjusted converter on feeding system, extrusion system and cutting system. Food grade stainless steel twin screw feeding machine, stable materials feeding in the whole food process. |

|

3 |

Gearbox with automatic lubrication function, extending gear life. |

|

4 |

Increased radiator on driving part for forced cooling effect, ensuring extruder operates safely. |

|

5 |

Barrel with water-cooled circulation, raw materials not only for corn/rice, also for wheat flour/starch with high viscosity. Different moisture-extrusion temperature ratio, whole-expanded and half expanded as different type of products. |

|

6 |

Cutting knife fixed in the die head seat, rotary cutting by V-belt drive. |

6.Application Of Crispy Chips/ Bugles /Sticks /Sala Processing Line

Flour Food Machine uses double screw extruding technique to replace the traditional steam boiling process. It includes mixing, cooking, extruding, and shaping process, no needing boiler, with simple process, high efficiency and little pollution.

The raw materials can be rice powder, corn powder, wheat flour individually or their mixture. Only by changing the moulds, shaping or cutting machine, the shapes can be various: Sticks, square sheet rib chips, diamond chips, wavy chips, pillow shapes and bugles etc. The taste is good and no greasiness.

Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines