- Shandong Loyal Industrial Co.,Ltd.

- Industrial Microwave Oven Food Extruder Machine Biscuit Making Machine

Home> Processing> Fried Food Preparation Production Line To Help!

Fried Food Preparation Production Line To Help!

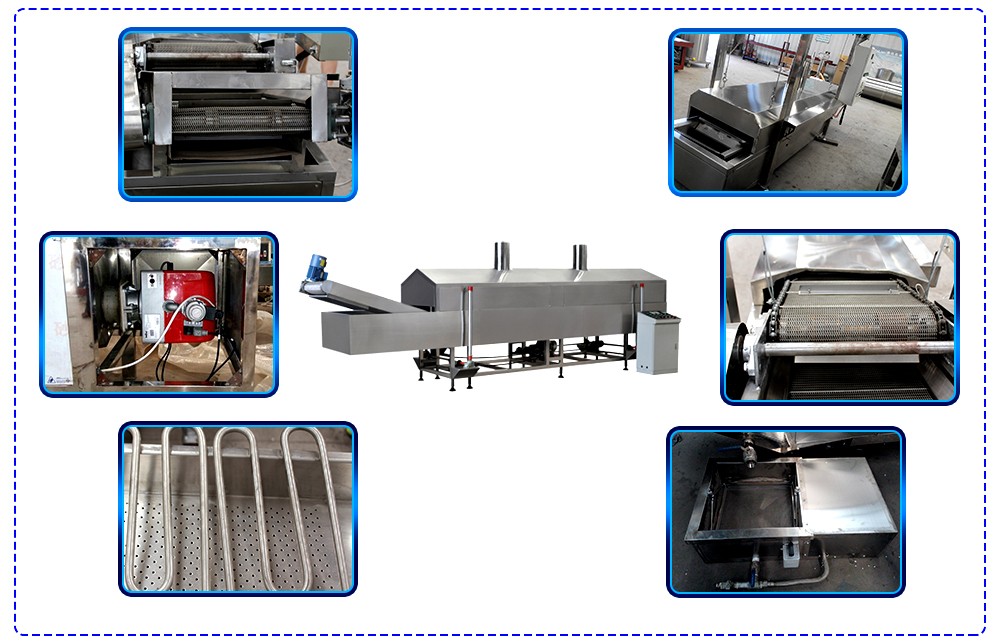

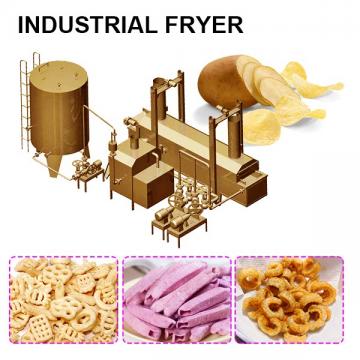

2020-10-10 10:00:39This automatic fryer machine is specially designed for the industrial production of frying, de-oiling, seasoning and cooling of food products. Chips frying machine production line includes feeding system, continuous frying system, de-oiling system, seasoning system and cooling system.

This automatic fryer machine is specially designed for the industrial production of frying, de-oiling, seasoning and cooling of food products. Chips frying machine production line includes feeding system, continuous frying system, de-oiling system, seasoning system and cooling system. It has the characteristics of high degree of automation, large output and continuous production.

The feeding system adopts frequency conversion speed regulation, with strong power, stable operation and energy saving.

The whole machine of the commercial deep fryer is reasonable in design, easy to operate and has excellent frying effect. Users can determine the type of deep fryer machine and the type of fryer used according to the actual production. The main types of our company's commercial deep fryer are divided into electric type and gas type, fuel type and hybrid type.

The length of the cooling system can be customized according to the actual product. At the same time, the cooling effect is excellent. And the customer can personally visit the machine.

The production line of large deep fryer has the advantages of easy operation, flexible collocation and combination, and easy maintenance. It minimizes human factors to ensure efficient and high-quality products. Wide range of applications, it can process puffed food, secondary puffed blanks, pasta products, beans, nuts, fresh fruits and vegetables, etc. According to different product characteristics, single-layer or double-layer mesh belt fryer can be equipped.

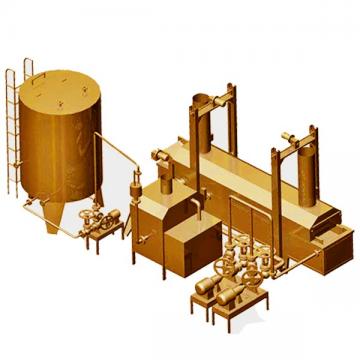

At the same time, the company provides related supporting facilities. Such as oil tanks, oil pumps, oil filters, pipeline connections and program operations, etc.. At the same time, it can realize real-time oil level monitoring, automatic oil replenishment, oil filtering and other functions to reduce production costs.

Automatic Continuous Deep Fat Fryers Machine

Automatic Continuous Deep Fat Fryers Machine Industrial Deep Fryer Machine Systems

Industrial Deep Fryer Machine Systems Automatic Deep fryer machine

Automatic Deep fryer machine Industrial Deep Fryer Oil Filter Machine

Industrial Deep Fryer Oil Filter Machine Instant Pasta Production Line

Instant Pasta Production Line 150Kw Fully Automatic Industrial Continuous Microwave Shrimp Drying Machine

150Kw Fully Automatic Industrial Continuous Microwave Shrimp Drying Machine Continuous Tunnel Honeysuckle Flower Drying Dehydrator Machine Tunnel Microwave Baking And Sterilizing Equipment

Continuous Tunnel Honeysuckle Flower Drying Dehydrator Machine Tunnel Microwave Baking And Sterilizing Equipment Automatic Microwave Frozen Meat Beef Thawing Machine

Automatic Microwave Frozen Meat Beef Thawing Machine