- Shandong Loyal Industrial Co.,Ltd.

- Industrial Microwave Oven Food Extruder Machine Biscuit Making Machine

Home> Application> Gypsum Board Microwave Drying Machine

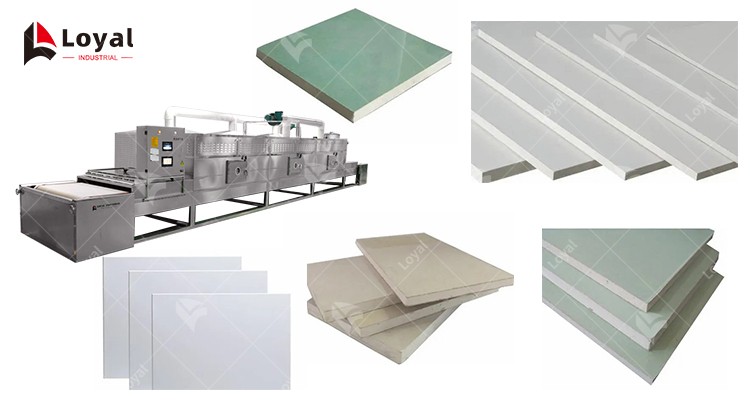

Gypsum Board Microwave Drying Machine

Introduction

The application and introduction of gypsum board microwave drying machine is an important process in the paper industry. It helps to control moisture, retard mold growth and improve tensile strength of the final product. Gypsum board is a type of paperboard made from gypsum, which is a mineral that has been dried. Gypsum board is used to make packaging materials, general office products, and other specialty papers. It is heat-sensitive and can be damaged by moisture, so it needs to be dried quickly to prevent mold growth and other problems. The gypsum board microwave drying machine is a valuable tool for the paper industry because it can speed up the drying process and reduce the risk of damage caused by moisture. The machine also helps to control the moisture level so that the boards don’t become brittle or difficult to handle.

Types of Gypsum Board Microwave Drying Machine

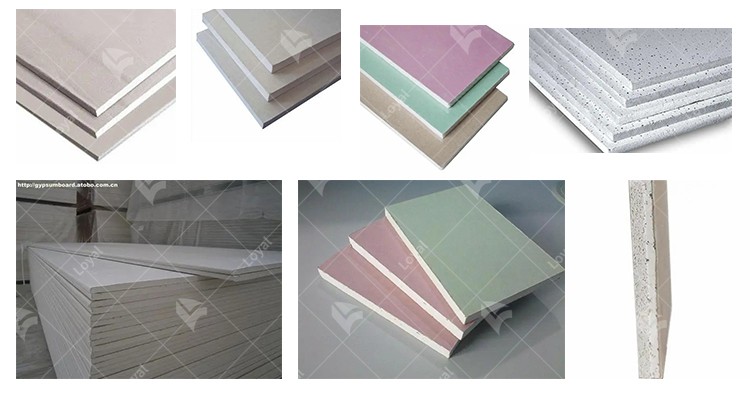

Gypsum board is a very common type of wallboard used in construction and decoration. Gypsum board is made of gypsum plaster and paper, which are mixed together, then formed into a sheet. Gypsum board is strong and lightweight, so it's often used as a decorative paneling or wallboard in residential and commercial buildings. Gypsum board can also be used for other purposes such as refrigerator shelves, countertops, and even boats.

There are several types of gypsum boards that can be dried by using a microwave. The most common type of gypsum board is called double-sided gypsum board because it has two faces: one face is cut to the correct size and shape, while the other face is roughed out so the adhesive can be applied. Single-sided gypsum board doesn't have this extra face, so the adhesive needs to be applied to only one side of the board.

There are two different types of adhesives that can be used to attach single-sided or double-sided gypsum boards to a surface: hot melt glue and an epoxy resin. Hot melt glue is often faster than epoxy resin, but they both work well. It's important to use the right amount of glue; too much glue will make the bond weak and the gypsum may not stay attached to the surface.

Once the glue has been applied, it needs time to dry.

Application of Gypsum Board Microwave Drying Machine

Gypsum board is used as a traditional wall and ceiling insulation material. It can be recycled and turned into a new product called gypsum board microwave drying machine. The gypsum board microwave drying machine has the function of reducing moisture in the gypsum board, so that it can be reused.

Advantages of Gypsum Board Microwave Drying Machine

There are many advantages of using a gypsum board microwave drying machine. These machines can help speed up the drying process, making it easier for you to get your products ready for market. Additionally, these machines can also help reduce the amount of time needed to dry items, which can save you money in the long run.

Conclusion

If you're in the market for a new microwave drying machine, then you'll want to take a look at the Gypsum Board Microwave Drying Machine. This machine is perfect for applications such as clothing restoration and dry cleaning, making it a versatile choice that can be used in many different settings. In addition, the machine is easy to operate, making it an ideal choice for anyone looking for a quick and easy solution.

Contact Us

- Shandong Loyal Industrial Co.,Ltd.

- Telephone+86 13256674591

- Email[email protected]

- WhatsApp+86 13256674591

- WeChat13256674591

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan

150Kw Fully Automatic Industrial Continuous Microwave Shrimp Drying Machine

150Kw Fully Automatic Industrial Continuous Microwave Shrimp Drying Machine Instant Pasta Production Line

Instant Pasta Production Line Industrial Microwave Date Drying Sterilizing Machine

Industrial Microwave Date Drying Sterilizing Machine Industrial Tunnel Continuous Microwave Dryer

Industrial Tunnel Continuous Microwave Dryer