- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Company News> How do they make cornflakes?

How do they make cornflakes?

2021-06-21 14:59:33The top six corn flakes production lines in sales of professional technical articles show that corn flakes are crisp food, with good rehydration, not rotten outside, smooth taste, and strong grain flavor.

Corn flakes is a very popular breakfast cereal. Now it has entered every family. Many office workers who are in a hurry to eat in the morning will also store some corn flakes in the office. It is convenient and quick to eat, and it is easy to use with milk. It is a nutritious breakfast.

The development of the Internet has made corn flakes known to more people. And all kinds of corn flakes are also emerging endlessly. We can always see advertisements about corn flakes in various places, so how exactly are corn flakes produced?

How do they make cornflakes?

The top six corn flakes production lines in sales of professional technical articles show that corn flakes are crisp food, with good rehydration, not rotten outside, smooth taste, and strong grain flavor. The primary raw material is cornflour, mixed with sugar, various vitamins, and minerals. After adding a certain amount of water, it is thoroughly kneaded, matured, shaped, pressed, baked, and seasoned to produce flakes.

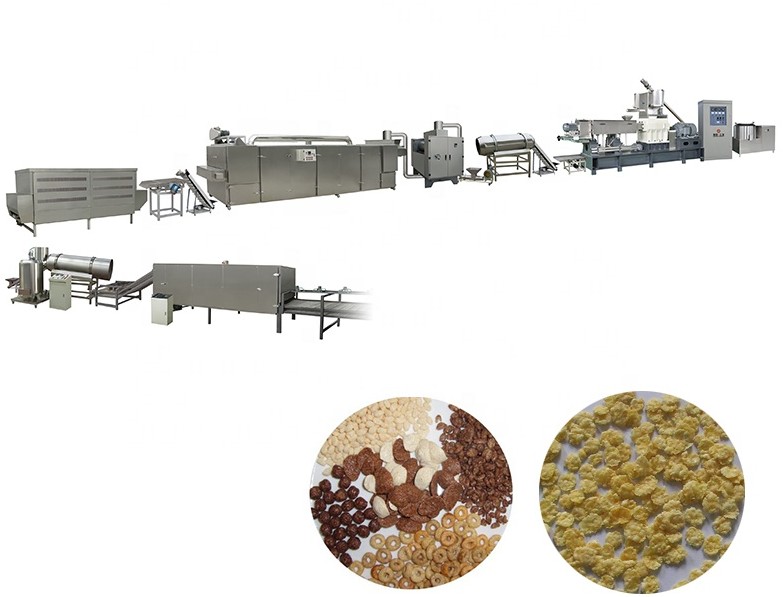

Corn flakes need to use professional production equipment in the production process——

Corn Flake Production Line, the primary production process is powder mixing——extrusion puffing——cooling——tableting——drying——seasoning——cooling——package.

The specific production process of corn flakes is as follows:

First, the cornflour, water, and other nutrients are transported into the flour mixer, and the flour mixer will evenly mix these raw materials. After that, the conveyor will transport the mixed raw materials to the technical machine. The extruder adopts advanced screw extrusion technology, which uses high temperature and high pressure to mature the mixture and expand it into a one-time completion. You can choose according to your own production needs—appropriate specifications.

The extruded corn flakes will then be transported to the vibrating screen for inadequate cooling. After cooling, the air conveyor will transport the corn flakes to the tablet press. The tablet press can compress the semi-finished products into flake-like products. Corn flakes are smooth and tidy and are more popular with consumers.

The finished corn flakes will be transported to the oven for high-temperature drying, forming a crispy taste, and can be stored for a long time after the moisture is lost. The range adopts a belt drying device, and a certain number of heating devices are installed in the content, which uses electric heating for drying. It is the most commonly used drying and dehydrating device for puffed products.

The dried corn flakes are conveyed to the sugar spraying machine. The sugar spraying machine is used to adjust the taste of the corn flakes. The front drum is used for flavoring, and the rear drum is used for spraying oil so that the seasoning and spraying are operated separately, and the corn flakes are flavored. The quality can be improved a lot.

The corn flakes are made at this point, and after cooling, they can be packaged using the packaging machine. The packaging machine can realize automatic packaging, with high weighing accuracy, from bag making to edge sealing, and the corn flakes after packaging are of a higher grade.

The above is the specific production process of corn flakes. Making corn into corn flakes is a highly complex process. The use of high-quality equipment can save raw materials and retain the nutrients in the raw materials to the greatest extent, making the taste of corn flakes richer.

Our company is a professional food machinery manufacturer with many years of experience in R&D and production. The Corn Flake Production Line produced has been exported to Singapore, Canada, Indonesia, Russia, and other countries, very recognized.

The equipment is made of food-grade stainless steel, which is durable and not easy to damage.

And can ensure the hygienic quality in the production process, and it is also very convenient to clean. It can provide consumers with healthy and sanitary corn flakes. In addition, the production line can realize continuous production. And the highly automated production method does not require manual intervention in the production process and has high production efficiency and low production cost. Our engineers can also provide customized services for manufacturers. You can tell us your needs, and we will customize the power and mold suitable for you. It is our goal to provide you with tremendous help.

Corn flakes are a very convenient breakfast cereal with a broad demand. It will usher in more remarkable development in the future. If you need it, please contact us!

Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines