- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Company News> How do you make textured vegetable protein chunks?

How do you make textured vegetable protein chunks?

2021-12-27 11:05:28In our daily life, textured vegetable protein chunks are more common. soya nuggets plant can produce soy protein and other foods. In recent years, textured vegetable protein chunks have become more and more diverse, not only adding some organic vegetable elements, but also increasing their vitamin content. There are many differences in its content and form, so it is becoming more and more popular.

In our daily life, textured vegetable protein chunks are more common. soya nuggets plant can produce soy protein and other foods. In recent years, textured vegetable protein chunks have become more and more diverse, not only adding some organic vegetable elements, but also increasing their vitamin content. There are many differences in its content and form, so it is becoming more and more popular.

Soy protein is a kind of plant protein. The amino acid composition of soy protein is similar to that of milk protein. Except for slightly lower methionine, the content of other essential amino acids is relatively rich. It is a plant-based complete protein. In terms of nutritional value, it can be equivalent to animal protein. It is also the closest to human body in terms of genetic structure. So it is the most nutritious plant protein.

Soy protein is a kind of plant protein. The amino acid composition of soy protein is similar to that of milk protein. Except for slightly lower methionine, the content of other essential amino acids is relatively rich. It is a plant-based complete protein. In terms of nutritional value, it can be equivalent to animal protein. It is also the closest to human body in terms of genetic structure. So it is the most nutritious plant protein.

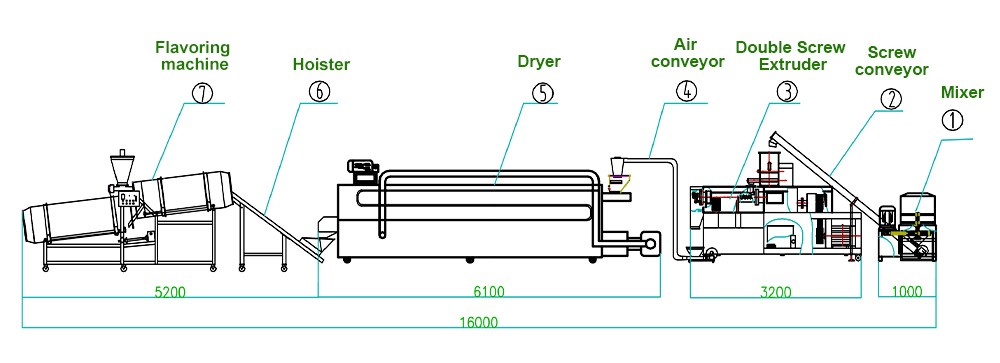

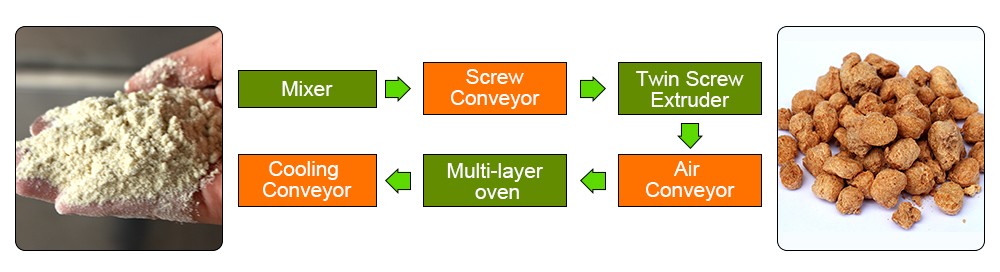

Process flow of soya nuggets plant

1.Mixer (mixing powder) → 2. Screw conveyor → 3. Twin screw extruder (extrusion, cutting and forming) → 4. Air conveyor (conveying) → 5. Oven (baking) → 6 .Cooling conveyor

The defatted soy flour that meets the specifications is mixed with 25%-30% water into the twin-screw extruder. In this machine, the moisture of the soy product is squeezed spirally under high temperature and high pressure, and then the atmospheric pressure is rapidly compressed to produce a dry soy product. Soy tissue is completely destroyed in the process of pressure reduction, and the digestibility is improved. Harmful physiological substances such as trypsin in soybeans are inactivated by heat, and the inherent beany smell and odor of soybeans are removed. The products can be made into products with special structures such as fibrous, porous structure, and sponge-like shapes. Package after cooling and drying.

The defatted soy flour that meets the specifications is mixed with 25%-30% water into the twin-screw extruder. In this machine, the moisture of the soy product is squeezed spirally under high temperature and high pressure, and then the atmospheric pressure is rapidly compressed to produce a dry soy product. Soy tissue is completely destroyed in the process of pressure reduction, and the digestibility is improved. Harmful physiological substances such as trypsin in soybeans are inactivated by heat, and the inherent beany smell and odor of soybeans are removed. The products can be made into products with special structures such as fibrous, porous structure, and sponge-like shapes. Package after cooling and drying.

The technical key and focus of this production line is the use of extrusion technology. After the material is expanded, the volume will be enlarged, the taste will be crispy, the starch will be gelatinized, and the water-soluble components will increase, which is easy to be absorbed by the human body.

Advantages of soya nuggets plant

|

1 |

The design is reasonable, the structure is compact, and the operation is very simple. |

|

2 |

The operation is highly automated, and only one or two people can complete the processing process, saving manpower. |

|

3 |

Stable performance and reliable quality. It is carefully researched and developed by a professional team to meet the needs of food processing. |

|

4 |

Low cost, high efficiency, low energy consumption, to ensure the whole process from feed to finished product. |

|

5 |

The output of the machine can be changed by configuring more extruders on one production line to meet higher output requirements. |

|

6 |

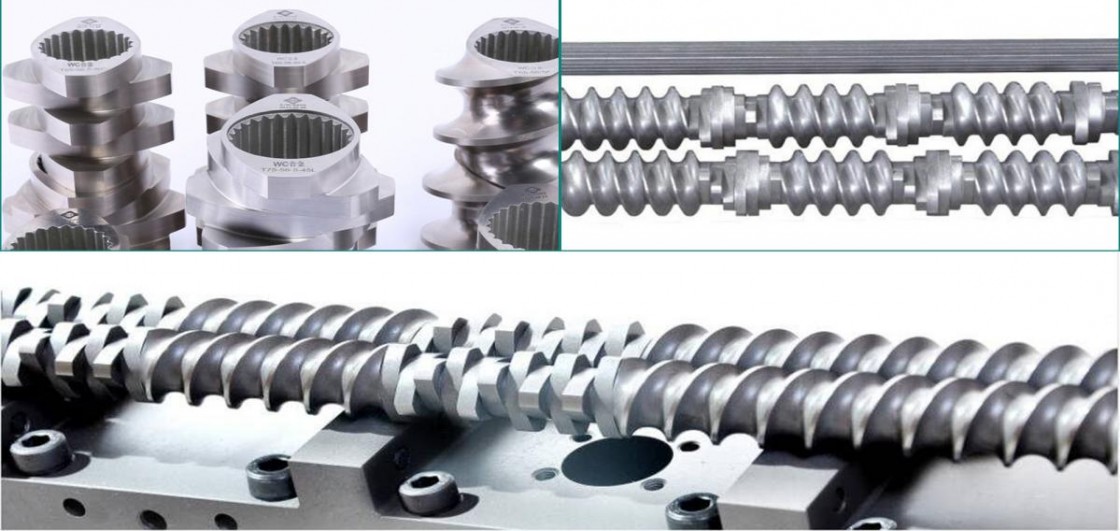

All machines are made of stainless steel, and the screws are made of alloy steel, with a modular system structure and self-cleaning function. |

The use of a twin-screw extruder production line to produce soybean tissue protein has the advantage of providing a variety of nutrients to the human body, solving the problem of single nutrition in the original technology, reasonable design, advanced technology, and high degree of automation. Soy protein products have good functionality and a wide range of applications.

Quality control of soya nuggets plant

1. Design control

The technicians make a scientific and reasonable design according to the specific requirements of the user and the actual situation of the test. And compile process cards for the whole process of equipment manufacturing.

2. Production control

The production must be based on technical documents, and the processed qualified products of each process must be marked. The identification of key components must be clear to ensure the traceability of the product.

4. Inspection control

If the finished product can be installed and started in the factory, the test machine inspection can be started in the factory, and the factory can only leave the factory after passing the inspection. After the installation is completed in the factory and the test machine is successful, an inspection certificate will be issued.

Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines