- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Processing> How Is Cereal Made? Nutritious Cereal Breakfast Extrusion Process Principle

How Is Cereal Made? Nutritious Cereal Breakfast Extrusion Process Principle

2020-07-07 18:05:53

Breakfast cereals are made from corn, rice, millet, sorghum, buckwheat, oat and other cereals or their mixed powder. Corn cereal raw materials contain many vitamins, minerals and proteins. Through analysis of relevant nutrients in cereal flakes, extrusion A food form processed by puffing technology that is easy to digest and absorb. This product is rich in carbohydrates, dietary fiber, and can also add essential amino acids, vitamins, minerals, sucrose, dietary fiber, soy lecithin, honey, wheat starch, calcium carbonate and other nutrients during processing, so the nutritional value is high . Through extrusion processing, the color and flavor of food are improved, and the products have different colors and varieties, which can meet different levels of consumer demand.

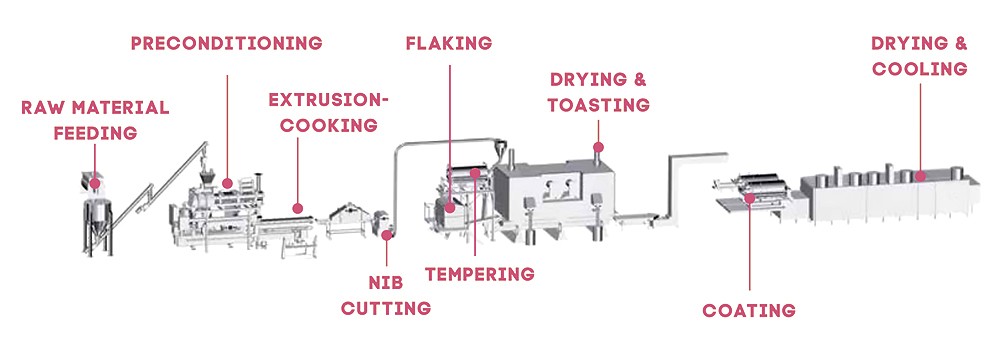

How is cereal made? Nutritious cereal breakfast extrusion process principle:

Extruder machine manufacturer in the extrusion proces to put the raw materials into the extruder at first. The raw materials move under the action of the screw and spiral in the extruder. Friction occurs between the materials, the barrel and the spiral, and the materials are sheared and extruded And mixing, so that the material can be refined evenly.

During the continuous mixing process, the temperature inside the twin screw extruder will increase and the pressure will increase. Under high temperature and high pressure, the material will become a paste, the starch in the material can be cracked and gelatinized, the protein will reorganize, and the fiber It will also be refined.

Extruder screw in the food making machine continuously rotate. When the material enters the extruder, it is transported forward with the rotation of the screw. Due to the strong friction and extrusion between the screw and the barrel, the material and the barrel, and the material The heat applied by the food processing machine sleeve makes the material in a molten state at high temperature and high pressure.

When the material enters the die, the molten material is completely in a fluid state. Finally, it is extruded from the die hole to reach the normal temperature and pressure state at an instant. The volume of the material It also instantaneously expands, causing many micropores to explode in the starch body inside the food, and the volume expands sharply, forming a puffed food with a loose texture.

The extrusion in food processing is a short-term process, the material is heated for a short time, which can maximize the preservation of the nutrition of the raw materials. During the extrusion process, due to the degradation of starch, fat and protein, it is conducive to the digestion and absorption of the human body. When the material is extruded from the die, part of the water is flashed off, which makes the a stereotyped and difficult to regenerate, and also extends the shelf life of food.

Using extrusion technology to process cereal breakfast, the high temperature and high pressure process destroys some harmful factors in the cereal, makes starch gelatinization, reduce fat content, protein degradation, improves the digestion and absorption rate of cereals, and can also give the cereal breakfast some cooked cereal aroma . Extrusion technology in food processing method can keep the nutrients of the grain to the greatest extent

Table 1 Effects of screw rotate speed on the quality of products

|

NO |

Feed speed/ (kg / h) |

Screw Speed/ (r / min) |

Moisture/ % |

Pressure/ MPa |

Sensory evaluation |

|

1 |

150 |

300 |

16 |

6.3~6.8 |

The bulk weight is too large, the color is dark, and the taste is blunt |

|

2 |

150 |

500 |

16 |

5.8~6.5 |

Moderate bulk density, delicate taste, good foam resistance, non-stick teeth |

|

3 |

150 |

700 |

16 |

5.5~6.0 |

The bulk density is small, the color is light, and the void is large |

Table 2 Effects of residence time on the extrusion and unit

weight

|

/ s |

Puffing degree |

volume-weight/ (g / L) |

|

27.5 |

1.51 |

0.29 |

|

Residence time3.5 |

1.33 |

0.63 |

Increased screw speed will result in increased temperature, shorter residence time, lower puffing rate, and lighter product color. If the screw speed is too high or the feed is too fast, the residence time of the material in the extrusion cavity is too short, and the expansion rate decreases; if the screw speed is too low or the feed is too slow, the material stays in the extrusion cavity for too long, the expansion rate also decreases. Therefore, the requirement for the screw speed is to ensure that the material is in a homogeneous state throughout the process, but also to match the conveying capacity of the screw with the amount of feed.

Table 3 Effects of additive amount of calcium carbonate on the characteristics of extrusion coarse grain breakfast food

|

Add amount/ % |

color |

Taste |

Flavor |

Organizational structure |

Appearance |

volume-weight/ (g / L) |

|

0.1 |

Yellowish white |

Delicate, sticky teeth |

Grain aroma |

Little Uniform |

Very rough and irregular |

106 |

|

0.3 |

Yellowish white |

Delicate, sticky teeth, alkaline smell |

Grain aroma |

Uniform |

Rough, irregular |

92 |

|

0.5 |

Yellowish white, bright |

Delicate, sticky teeth, alkaline smell |

Grain aroma |

Uniform |

Less Smooth, regular |

87 |

|

0.7 |

Yellowish white, bright |

Delicate, sticky teeth, alkaline smell |

Grain aroma |

Uniform |

Smooth, regular |

103 |

Addition of calcium carbonate in the extrusion process

Adding calcium carbonate can make the structure of extruded grain even and fine. The reason is that during the extrusion process, calcium carbonate does not undergo a rheological phenomenon like starch molecules, and can act as a bubble nucleus, so that bubbles form uniformly around the fine particles of calcium carbonate. When the amount of calcium carbonate is 0.5%, the specific volume of the product is the smallest, that is, the degree of expansion is the largest. When the added amount of calcium carbonate reaches 0.3%, the alkali astringency appears. Therefore, the addition amount of calcium carbonate in the production of cereal extrusion products is preferably 0.1% ~ 0.3%

The best operating parameters of breakfast cereals:

The addition amount of sugar is generally suitable at 7%~9%.

The optimal combination of process parameters for extrusion processing of cereal nutritious breakfast foods is processing temperature 180 ℃, screw speed 120 r/min, feeding speed 16 r/min, die diameter 6 mm, corn, rice, millet mixing ratio 6:2 : 2 (m/m), the material adjusts moisture 16%, salt addition 0.5%, sugar 8% (m/m), sodium cyclamate 0.1%.

The amount of water added to the material is 11% to 14%, the screw speed is 294 to 320 r/min, and the material feed speed is 960 to 980 kg/h;

The amount of water added to the material is 11% to 14%, the screw speed is 260 to 290 r/min, and the material feed rate is 1010 to 1040 kg/h.

Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines