- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Company News> How To Make Corn Flakes Automatically?

How To Make Corn Flakes Automatically?

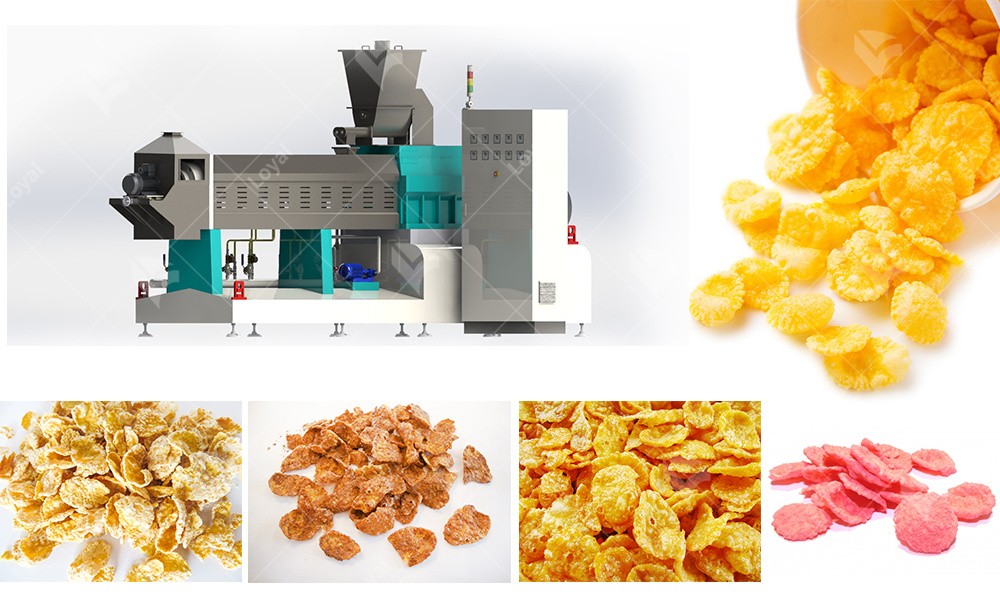

2023-02-17 10:06:32Introduction Of Corn Fakes Making Machine:

The corn flakes machine is a marvel of engineering, carefully designed to transform raw corn into the tasty flakes that we all know and love. It works tirelessly, day in and day out, to produce a consistent and high-quality product that has become a staple of breakfast tables everywhere.

Thanks to the corn flakes machine, we can enjoy a delicious and nutritious breakfast each and every day, without having to spend hours in the kitchen preparing our food. It is a true testament to human ingenuity and innovation, and it deserves all the praise that we can give it.

The Corn Flakes Production Line Details :

|

Capacity |

120kg-1000kg |

|

Power Supply |

Based On 380V 50 Hz 3 Phase. Customized According To Your Local Power. |

|

Machine details |

1.Stainless Steel,:201, 304, 316, On Request 2. Electric Parts Can Be Abb, Delta, Fuji, Siemens; Famous Brand As Your Demand. |

|

Certificate |

Ce,Gost,Tuv,Bv |

|

Raw Material |

Wheat Flour, Corn, Rice, Oat, Etc. |

|

Products Color |

White, Yellow |

|

Products type |

Original, Honey,Chocolate,Frosted,Gluten-Free,Organic,Etc. |

Flow Chart Of Commercial Corn Flakes Processing Line:

Grinding→Extruding→Drying→Toasting→Coating→Packaging

The Equipment Using In The Corn Flakes Making Machine:

1 Powder Mixer - 2 Screw Conveyer -3 Twin Screw Extruder -4 Vibration Cooling -5 Air Feed Machine -6 Drum Dryer -7 Air Feed Machine -8 Press Machine -9 Air Feed Machine - 10 Predryer -11 Elevator -12 Vibration Feeding -13 High Temperature Baking -14 Sugar Pan (Optional) -15 Sugar Spraying System -16 Yanshen Oven -17 Cooling Conveyor -18 Packing Machine -19 Box Packing Machine

Feature Of Corn Flakes Machines:

1Automatic operation: Corn flakes machines are typically designed for automatic operation, which reduces the need for manual labor and increases efficiency.

2.Capacity: Corn flakes machines are available in a range of sizes, with different capacities to suit different production needs.

3.Material handling systems: Corn flakes machines often include material handling systems that can handle large quantities of raw materials, such as corn grits, sugar, and other additives.

4.Extrusion system: The extrusion system is a critical part of the corn flakes machine that shapes and cooks the raw materials to create the corn flakes.

5.Drying system: After the extrusion process, the corn flakes are dried using a hot air drying system, which removes any remaining moisture and ensures that the flakes are crispy and crunchy.

6.Coating system: Once the corn flakes are dried, they may be coated with sugar or other flavoring using a special coating system.

7.Quality control: Corn flakes machines typically include quality control systems that ensure that the finished product meets the desired standards of quality and consistency.

8.Easy to clean: Corn flakes machines are designed to be easy to clean, with removable parts that can be easily disassembled and cleaned.

Overall, corn flakes machines are complex pieces of equipment that are designed to handle large quantities of raw materials and produce high-quality cereal products efficiently and consistently. They are a critical component of the commercial production of corn flakes and other breakfast cereals.

Parameter Of Corn Flakes Machine:

|

Model |

Installed Power (KW) |

Power Consumption (kw) |

Capacity (kg/h) |

Dimension (m) |

|

LY65 processing line |

140kw |

90kw |

120-150kg/h |

39*1.2*2.2 |

|

LY70 processing line |

160kw |

120kw |

180-220kg/h |

41*1.5*2.2 |

|

LY85 processing line |

190kw |

140kw |

300-500kg/h |

43*3.5*4.3 |

|

LY90 processing line |

240kw |

190kw |

800-1000kg/h |

65*5.0*4.3 |

Applications Of Corn Flakes Production Line:

Corn flakes production lines are used in commercial or industrial settings to produce corn flakes, a popular breakfast cereal made from corn. The applications of a corn flakes production line include:

1.Breakfast cereal production: The most common application of corn flakes production lines is for the production of breakfast cereals, which are consumed by millions of people around the world.

2.Snack food production: Corn flakes can also be used as a base for other snack foods, such as cereal bars or trail mix.

3.Animal feed production: Corn flakes can be used as a source of nutrition for livestock, such as chickens or pigs.

4.Ingredients for other food products: Corn flakes can be used as an ingredient in other food products, such as bread, muffins, or other baked goods.

5.Export: Corn flakes are a popular food product in many countries, and corn flakes production lines can be used to produce corn flakes for export to other countries.

Overall, corn flakes production lines have a wide range of applications in the food industry, and they are a critical component of the commercial production of corn flakes and other breakfast cereals.

Machine Photos Of Corn Flakes Production Line:

Machines Materials: All the machines are made by stainless steel.

Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines