- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Company News> LOYAL TO EXHIBIT AT PET FAIR ASIA

LOYAL TO EXHIBIT AT PET FAIR ASIA

2023-08-30 14:14:10The 25th Pet Fair Asia 2023 was successfully concluded on August 20th. Through wind and rain, across the cycle, the exhibition along with the development of the industry continues to refine and upgrade, to show the industry as the "global pet industry flagship exhibition" unique brand charm and exhibition benefits. There were 101,372 professional visitors and 352,169 visitors. Our company also participated in the Pet Fair Asia, which was given great expectations by the industry in terms of exhibition scale, audience quality, industry links and brand effect. In the 5-day exhibition hall covering 230,000 square meters, more than 1,000 industry leaders, 2.4W+ global brands, 20 professional summits and forums, 40+ brand promotions and releases, a variety of exciting events, cross-border creativity, combined with the flow of KOL platforms, focusing on the whole industry, linking the industry to the exhibition, and comprehensively demonstrating the latest development of the pet industry in China and the practice of innovation, and harvesting the praise and recognition of the exhibitors and visitors. The show has gained praise and recognition from exhibitors and visitors.

The long-awaited industry event will expand the release of the industry's trade demand, 3 days of professional day business negotiation atmosphere warm, exhibiting brand news, but also won the praise of exhibitors. The enthusiasm of the audience and the gains of the exhibitors reflect that the pet industry is ushering in a strong recovery, and that it is boosting the belief and confidence in the continued recovery of the pet economy.

Situation On Site

The exhibition area is also further optimized with the expansion of the exhibition scale, with 17 halls with distinctive themes, the three major exhibition areas of pet supplies, pet food and medical and health care products are still strong and have obvious advantages, while the international exhibition area, which is three years after the show, welcomes the strong assembly of five overseas pavilions from New Zealand and Japan and South Korea, which will further set up a platform of cooperation and exchange for Chinese and foreign enterprises. The exhibition integrates the whole industry chain to create a one-stop trade and exchange platform for the pet industry.

Company Booth Diagram

At the exhibition site, our company actively participate in the interaction, bring a fun and energetic full of wonderful sharing, appreciate the pet industry hot spot, docking the latest and most complete industry information, and come to all kinds of interactive and interesting activities, focus on the popularity of the show to enhance the atmosphere.

Company Booth Display

What Is Cold Pressed Pet Food

The basic concept of cold pressed pet food:It is to place the raw materials in a low-temperature state of 90 ℃ -120 ℃ in the oven for baking, and then use the dryer to dry and dehydrate. Cold pressed pet food, most of the raw materials into the 80-100 ℃ (different manufacturers of different production processes) or so in the oven, the use of low-temperature baking, so that the feed is slowly cooked, baking and molding, the particles are crunchy and easy to digest, the surface is dry and non-greasy, slowly cooked particles without air chamber, the surface does not spray oil, do not spray flavoring agents, the density per unit of volume is relatively low, to maintain the ingredients of the original nutrients of full-price food for pets.

The Processing Flow Of Cold Pressed Pet Food

Raw Material Preparation → Crushing And Sieving → Mixing And Dosing → Extrusion → Cutting → Low Temperature Drying → Cooling → Finished Product

Dr. Aldrich of Kansas State University in the United States and Dr. Hans-Jochen Büngener of Germany specifically did a test to study the difference between cold-pressed and puffed food. Conclusions were obtained: (1) Cold-pressed pet food is a more uniform looking, light brown pet food compared to puffed food. Cold-pressed food was lower in mass bonding, hardness and initial crispness than expanded food, but had more powder and coating needs, mainly due to the lack of mechanical energy input during baking, resulting in limited starch pasting in the baked product. (2) Cold-pressed pet food have more bitter and aftertaste, and the rest of the flavor profiles (e.g., grain aftertaste, salty aftertaste, bitter aftertaste, vitamin aftertaste, musty aftertaste, butter aftertaste, and fish aftertaste) are lower than those of expanded grains.

Applicable Raw Materials

Fresh meat: chicken puree, chicken bone puree, minced fish, beef puree and other types of meat paste puree to improve animal protein content;

Potatoes: purple potatoes, cassava, potatoes and other types of potato raw materials powder with low risk of allergy, supplement carbohydrates;

Functional raw materials: vegetable powder, fruit powder and all kinds of powdered small ingredients to ensure balanced nutrition;

Attractive: animal raw material hydrolysate, animal fats, egg yolk powder, whey protein powder and other raw materials can be mixed with the main ingredients to improve palatability

Characteristics Of Cold-Pressed Pet Food

Cold pressed pet food is selected as grain-free food, using lentil, potato and cassava flour as the carbohydrate source, which can avoid the allergy problems caused by grains and is hypoallergenic; high in fresh meat, low in carbohydrates, and most of the proteins are animal proteins;

Chicken fat and a small amount of added chicken hydrolyzed powder and brewer's yeast powder are safe ingredients that can improve palatability; multiple probiotic fermentation products are added, which are friendly to the stomach and intestines; chelated minerals are safe and more easily absorbed;

No indiscriminate/controversial ingredients;

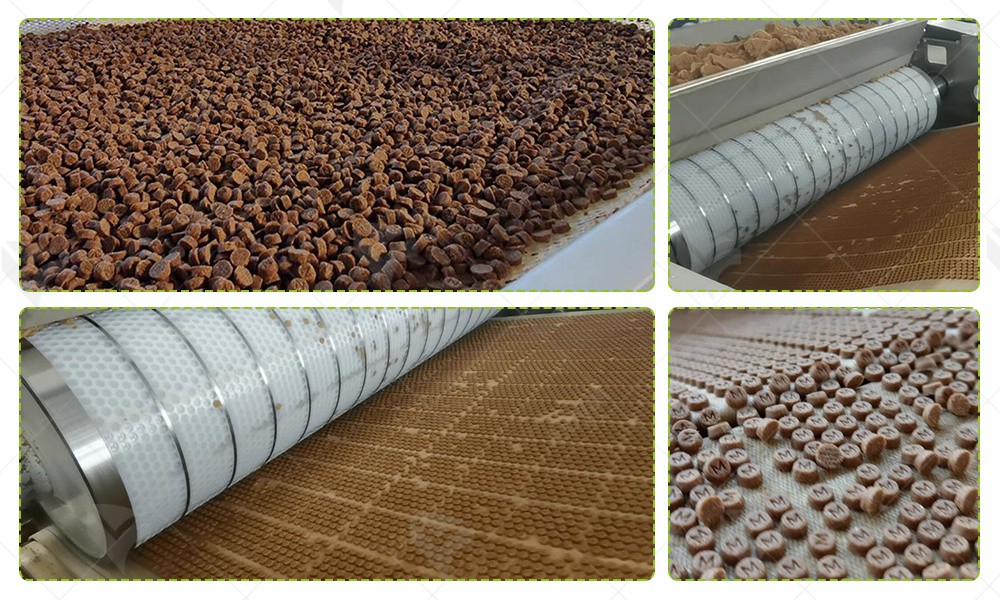

Cold pressed pet food can be made in different shapes, patterns and product logos according to the design of the mold.

Pet Food Development Prospects

Pet food market has great potential. With the rapid development of the economy and modern consumer concepts of renewal, pet food is the fastest speed into the city with pets in the family. Pet food is specifically for pets, small animals to provide food, between human food and traditional livestock and poultry feed between the high-grade animal food. In the current pet food market, the most popular pet food are baked food, cold pressed food, puffed food and sandwich food, as well as all kinds of pet chews, snacks, air-dried meat meat sticks.

The pet food production line of Shandong loyal intelligent machinery Co., Ltd can produce all kinds of pet staple food, snacks and all kinds of aquatic feed. We have a wide range of models, including pet-specific twin-screw extruders, cold pressed pet food extruders for small and large outputs.

Pet food is the most basic and important part of the pet industry chain! Compared with other parts of the pet industry chain, pet food runs through the whole life cycle of pets, and has the characteristics of high re-purchase, relatively stable price and high stickiness.

Welcome to visit our company to understand the product process.

Company Profile

Shandong loyal intelligent machinery Co., Ltd. is a manufacturer of snacks extruder machine, hot air drying Machine, frying system, industrial microwave system, biscuit making machine, cereals bar making machine, fruit and nuts process making machine, instant noodle process machine and a standing director of China Food and Drying Equipment Industry Association.The self-developed twin-screw extruder and single-screw equipment of shandong loyal intelligent machinery Machinery have been used in production: Puffed snack food, breakfast cereal corn flakes, fried pasta, bread crumbs, fruit chips, baby food, textured soy protein (TSP) food, fish feed and pet food. A variety of snack production line supporting products. At the same time, the batching, drying, flaking, baking, frying and spraying equipment matching the twin-screw extrusion system have all achieved independent design and production.Our company can provide food production equipment, process, formula development and application for a wide range of users. We are able to provide customers with complete project solutions, advice, planning, project design and engineering for food plants according to their specific requirements. Complete turnkey systems, centralized control systems, complete plant automation projects. Provide the installation, commissioning of machines and training of workers for customers.

Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

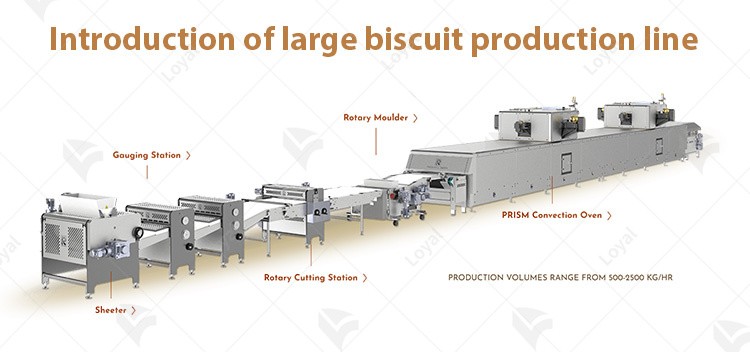

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines