- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Company News> Microwave Process

Microwave Process

2023-03-01 09:30:10Ⅰ. Introduction Of Microwave

Microwave is an electromagnetic wave with frequency range from 300MHz to 300GHz, and its wavelength is about 1m to 1mm, which can be further subdivided into decimeter wave, centimeter wave and millimeter wave, and its corresponding frequencies are UHF (ultra-high frequency), SHF (super high frequency), and EHF (extremely high frequency). (EHF, extremely high frequency).

With the development of modern microwave technology, sub-millimeter waves with wavelengths below 1 mm are also considered to be microwaves, which is equivalent to further expanding the frequency range of microwaves to higher frequencies. Therefore, some literature also defines the frequency range of microwaves as 300MHz ~ 3000GHz.

With the development of modern microwave technology, sub-millimeter waves with wavelengths below 1 mm are also considered to be microwaves, which is equivalent to further expanding the frequency range of microwaves to higher frequencies. Therefore, some literature also defines the frequency range of microwaves as 300MHz ~ 3000GHz.

Ⅱ. Microwave Characteristics

Microwaves usually exhibit three characteristics: penetration, reflection and absorption. For glass, plastic and porcelain, microwaves almost penetrate without being absorbed; for water and food, they will absorb microwaves and make themselves hot; and for metal things, they will reflect microwaves. From an electronic and physical point of view, the microwave electromagnetic spectrum has the following important characteristics that are different from other wavebands.

1、Penetration

Microwaves than other electromagnetic waves used for radiation heating, such as infrared, far-infrared wavelengths longer, and therefore has better penetration. Microwave penetration into the medium, due to the microwave energy and the medium to interact with a certain microwave frequency of 2450MHz, so that the molecules of the medium 2.45 billion vibrations per second, the molecules of the medium between each other to produce friction, caused by the rise in the temperature of the medium, so that the internal and external heating of media materials almost simultaneously warmed up, the formation of the body heat source state, greatly reducing the conventional heating in the heat transfer time, and in Conditions for the medium loss factor and medium temperature is a negative correlation, the material inside and outside heating uniform.

2、Selective Heating

The ability of the material to absorb microwaves, mainly by its medium loss factor to determine. Dielectric loss factor of the material on the absorption capacity of microwave is strong, on the contrary, the medium loss factor is small material absorption capacity of microwave is also weak. Due to the differences in the loss factor of each substance, microwave heating shows the characteristics of selective heating. Different substances, the resulting thermal effect is different. Water molecules are polar molecules, the dielectric constant is large, the dielectric loss factor is also large, the microwave has a strong absorption capacity. Protein, carbohydrates and other dielectric constant is relatively small, its absorption capacity of microwaves is much smaller than that of water. Therefore, for food, the amount of water content has a great impact on the microwave heating effect.

3、Small Thermal Inertia

Microwave heating of the medium material is instantaneous heating and warming, warming speed. On the other hand, the microwave output power can be adjusted at any time, the medium temperature can be changed without inertia, there is no "residual heat" phenomenon, is extremely conducive to automatic control and the need for continuous production.

4、Like Light

Microwave wavelength is very small, when the microwave irradiation to some objects, will produce significant reflection and refraction, and the light of the reverse, the same refraction. At the same time, the characteristics of microwave propagation is similar to geometric optics, can be as straight as light propagation and easy to focus, that is, with light-like.

5、Information

The information capacity of the microwave band is very large, even if the relative bandwidth is very small, the available frequency band is also very wide, up to hundreds or even thousands of megahertz.

6、Non-Ionizing

The quantum energy of microwave is not large enough, and thus will not change the internal structure of the material molecules or destroy the chemical bonds of their molecules, so the effect between the microwave and the object is non-ionizing.

Ⅲ. Microwave Technology In Various Industries For Application And Development

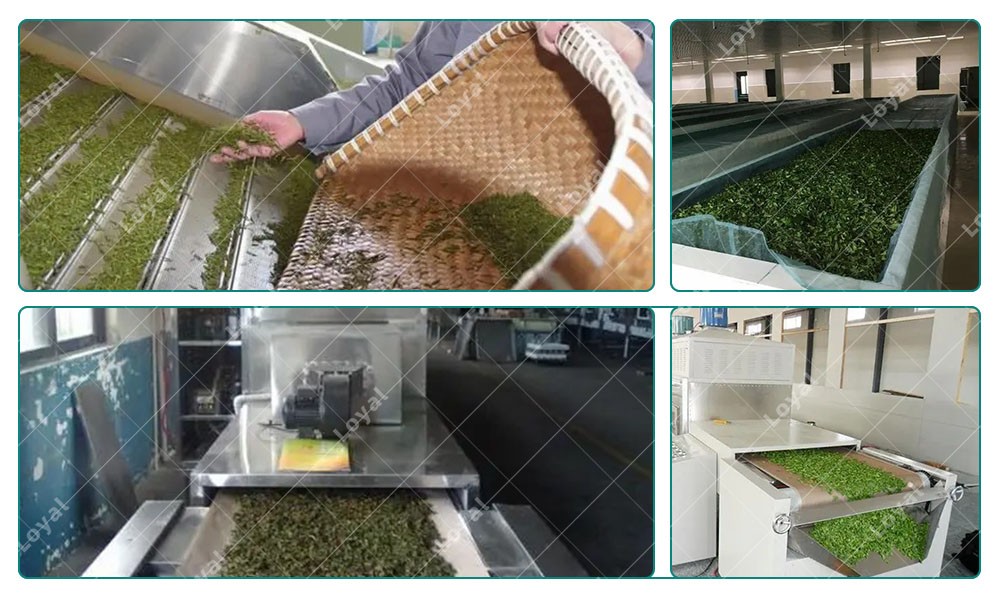

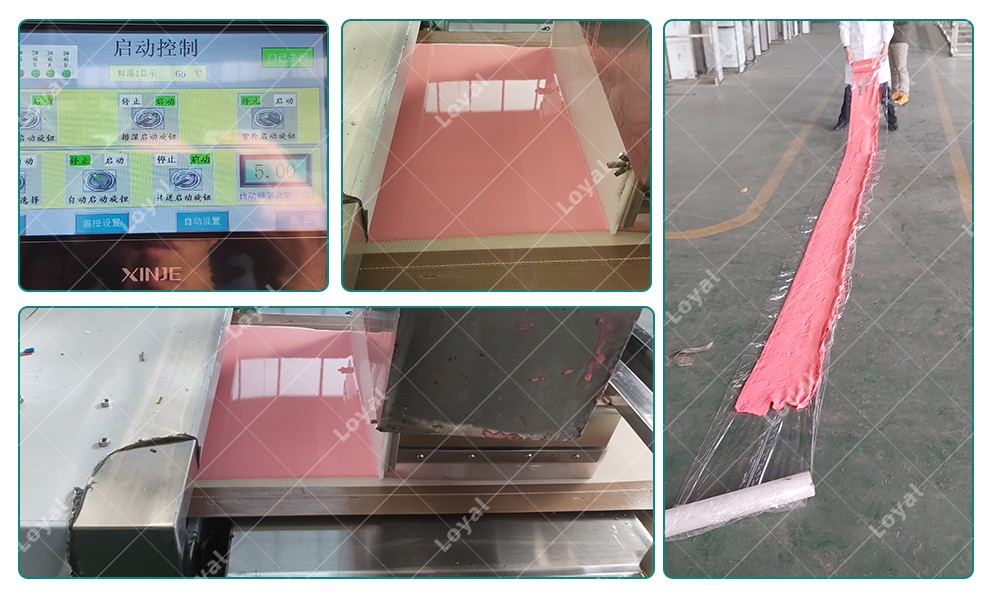

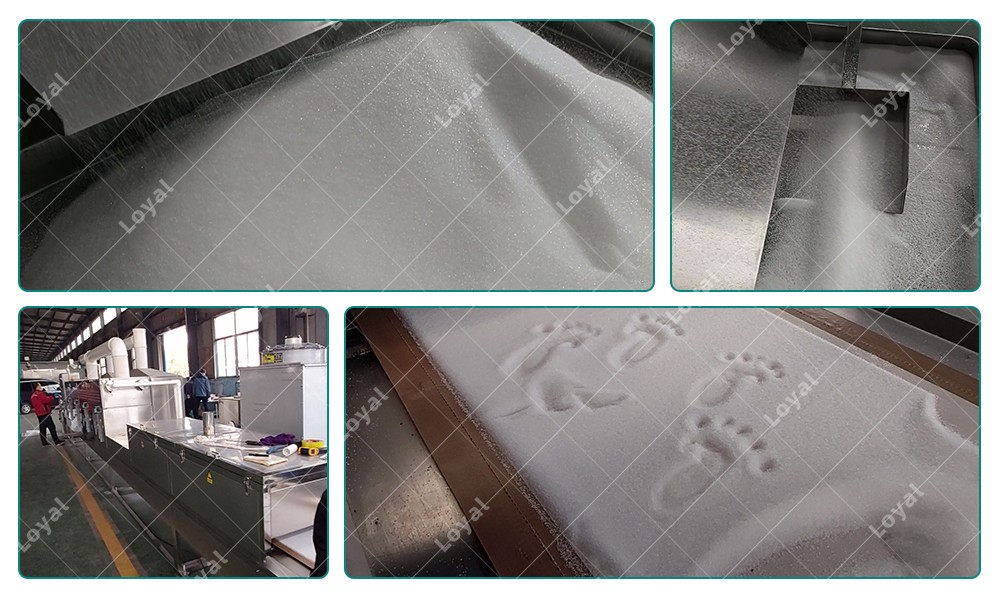

1、Food And Health Care Products Industry

The use of microwave food, health products can be sterilized, dehydration, drying, puffing, flavoring, deodorization, thawing, aging and preservation treatment. At present, it has been used in the production of milk powder, cheese, bone-strengthening powder, ginseng pills, bean powder, moon cakes, pastries, instant noodles, beef jerky, dried meat, meat strips, meat floss, dried fish flakes, fish floss, shellfish, duck in brine, thawed fish and poultry eggs, pickles, potato chips, cashew nuts, peanuts, melon seeds, soybeans, white wine, yellow wine, beer, milk, oral liquid, Chinese herbal medicine, etc.

2、Wood Processing

2、Wood Processing

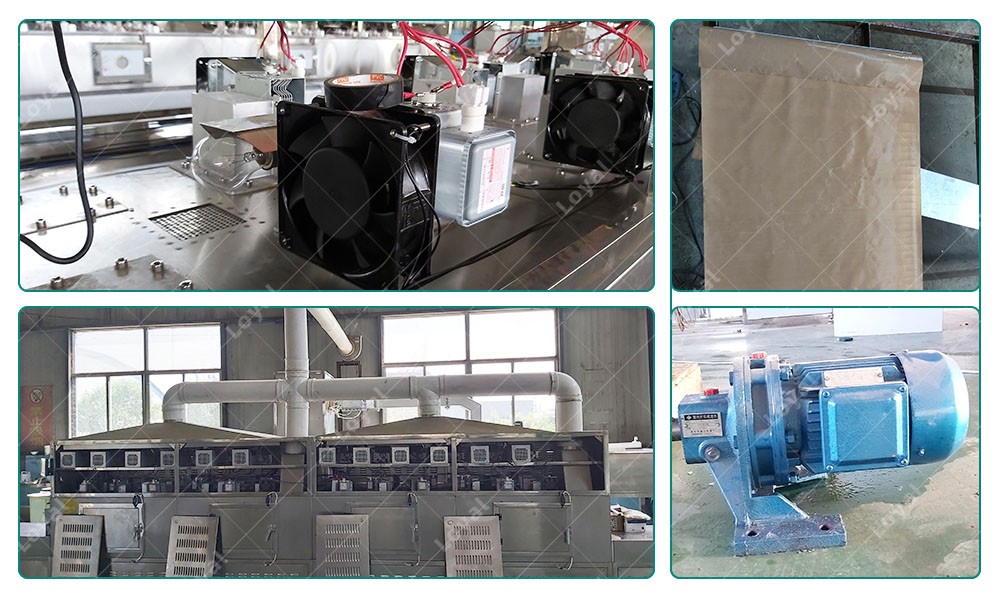

The use of high-power microwave dryer for 2-10 cm thick boards for drying, drying speed, wood does not crack, small deformation, while killing the internal wood ova and larvae, medium and high-grade furniture, flooring, packaging materials use of wood is the most suitable for processing. Microwave can also be ideal for curing treatment of bamboo wood composite panels and splice board crossover.

3、Insecticide Sterilization

Application of microwave heating technology can sterilize and kill insects at lower humidity, if the microwave treatment of food and materials, at 50-80 degrees can play a role in killing and sterilizing insects. Currently widely used to rice, grains, beans, tobacco treatment, bamboo, wood, paper, food, medicine and other industries.

4、Rubber Industry

Microwave technology applied to the rubber vulcanization process in the rubber industry, combined with conventional heating and insulation, greatly improving the time and efficiency of rubber vulcanization. At present, it is widely used in Hengshui area in Hebei and Shandong.

5、Ceramic Industry

5、Ceramic Industry

Microwave high temperature can be applied to the ceramic industry, the combination of traditional heating and microwave heating methods used, can greatly reduce the drying time of ceramics, while not affecting the ceramic firing rate of the finished product.

6、Coal Drying

6、Coal Drying

Coal mining is usually high water content (about 35%), if the conventional drying method for drying, slow, low efficiency, drying is not complete, the use of microwave method of drying, can make the coal inside and outside the simultaneous heating, is the evaporation of water to achieve dehydration and drying, the efficiency is greatly improved.

7、Microwave Plasma Technology

Semiconductor production process has been used in microwave plasma technology, can be etched, sputtering, vapor deposition, oxidation of silicon wafers; can be used for metal, alloy, non-metal surface treatment; can be used for high-temperature sintering of ceramics; can be used for plasma spectral analysis, can detect more than a dozen elements, in addition to the decomposition of toxic compounds.

8、Microwave Medical Waste Treatment Technology

The use of microwave technology in an oxygen-free or oxygen-deficient state, so that the microwave carrier quickly rise to a high temperature, so that medical waste in a very short period of time quickly in a high-temperature state, directly ashing, greatly reducing the generation of toxic gases in the combustion process. Gas in the flue gas and then use microwave plasma torch for high-temperature cracking, the entire treatment process and treatment environment to achieve fully enclosed harmless treatment. The application of this technology is superior to conventional treatment methods, opening up a new field of microwave applications.

9、Sewage Treatment

The use of microwave non-thermal effect and thermal effect of the selection of wave absorption "sensitizer" to microwave energy to the pollutants in the water and induce chemical reactions, through the physical and chemical effects of pollutants in the water degradation, transformation, accelerating the fluid in the solid, liquid separation, so as to achieve the purpose of sewage purification, is a new revolution in the field of water treatment.

10、Microwave Carbon Production

The use of microwave technology to crack bamboo at high temperature to make bamboo charcoal, greatly improving production efficiency, but also can extract to bamboo vinegar liquid, bamboo tar and other products, has a high economic value, better than the traditional kiln method of making bamboo charcoal, is now vigorously began to promote the use.

11、 The Development Of Microwave Technology In The Field Of Communications Status

Entering the 21st century, microwave technology continues to play a huge role in the field of broadcasting, cable television, telephone and wireless communications, in other areas such as computer networks and other applications have also emerged. In radio and television, the current radio and television program production is gradually going digital, and digital programs need digital means of transmission, so SDH digital microwave network came into being, compared with the old analog microwave equipment transmission capacity has increased significantly, SDH digital microwave equipment can transmit dozens of television programs and dozens of sets of sound broadcast programs, and the transmission distance is greater, a wider range. The use of digital microwave digital environment, but also to build a two-way interactive information network, to achieve the comprehensive use of network functions and development.

In the field of communications, microwave and satellite and fiber optic cable are among the three pillars of modern communications transmission. Microwave communication has its own unique advantages, first of all, microwave communication has good disaster resistance, floods, wind and earthquakes and other natural disasters, microwave communications are generally unaffected. 1976 Tangshan earthquake, the coaxial cable between Beijing and Tianjin all broke, but the six microwave channels can still work normally. Second, the formation of microwave transmission system more quickly. As the city continues to expand and unexpected events, such as local water, road damage, local fires and fires, etc., these occasions require the rapid establishment of a local temporary communication system. Microwave in the above-mentioned emergency response capabilities are far beyond the reach of other communication methods.

The rapid development of the network has brought about the urgent need for network communication line construction, although fiber optic cable has the advantage of large capacity, but also has a high cost, need to be laid in advance and vulnerable to natural disasters and other weaknesses, in addition to fiber optic communication is not suitable for rural areas, islands and other remote areas and special communication networks. Microwave communication can be used as a backup and supplement to the mainline fiber optic transmission, solving the problem of laying wired resources in urban areas. Digital microwave access has become another important way to establish wide area network connections, and is an effective supplement to urban communications infrastructure.

Digital microwave technology will be the main direction of the future development of microwave technology, specific applications include microwave spread spectrum data transmission system, can be used for urban short-range spur connection of high-band microwave, for the future of broadband service access to local multipoint distribution services, modern military digital microwave communication system and so on. The key technologies to focus on the study of high-band transmission technology above 10 GHz and compatible technology in the existing frequency band, including high-efficiency modulation technology, spread spectrum and frequency hopping anti-jamming technology, error correction technology and so on. In addition, such as microwave monolithic integration, fully digital processing, digital special integrated circuits and other technologies to improve reliability and reduce costs also need further research.

Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines