- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Company News> Pet Feed Production Line

Pet Feed Production Line

2023-02-28 09:20:40A pet feed production line is a system designed for the mass production of pet food. It typically involves a series of machines and processes that are used to mix, grind, extrude, dry, and package various ingredients into finished pet food products.The pet feed production line can be used to produce a wide range of pet food products, including dry kibble, wet canned food, and treats. The pet feed production line can be customized to produce specific types of pet food, such as food for dogs, cats, birds, fish, or other animals.Pet feed production lines are used by pet food manufacturers and can vary in size and complexity depending on the needs of the business. They are an important component of the pet food industry and help ensure that pet owners have access to a wide variety of high-quality pet food products.

The Flowchart Of Pet Feed Process Line

- Mixer --- 2. Scre Conveyor --- 3. Twin Screw Extruder --- 4. Air Conveyor --- 5. Muliti-Layer Oven --- 6. Hoister --- 7. Flavoring Line --- 8. Cooling Conveyor --- 9. Packaging

The Function Of Pet Feed Process Line

- Raw Material Handling: The pet food process line starts with the handling of raw materials such as grains, vegetables, meat, fish, and other ingredients that are used to make pet food. The raw materials are stored, sorted, and cleaned before being processed.

- Mixer:The raw materials are ground, mixed, and blended to create a homogenous mixture that meets the nutritional requirements of the target pet species. The mixture is then transferred to the next stage for further processing.

- Screw Conveyor: Screw conveyor can not only convey on the level but also by any angel these materials can be conveyed in the stainless steel roller without leaking, dust pollution; meanwhile it can send the self-mixer to the feeding machine or the conditioner and directly send the discharge hole of the inflating extruder.

- Twin Screw Extruder: The mixture is extruded through a die to form the desired shape and size of the pet food product. The extrusion process also ensures that the product is cooked and sterilized to eliminate harmful bacteria and pathogens.

- Muliti-Layer Oven:The oven is a multi-layer circulating drying box with good heat preservation effect and high efficiency and energy saving.The extruded products are dried and cooled to remove excess moisture and reduce the risk of spoilage during storage and transportation.

- Flavoring Line:The finished products are coated with oils, fats, and other ingredients to enhance their flavor and texture.

- Packaging:The products are then packaged in bags or containers that are suitable for storage and transportation.

The Parameter Of Pet Feed Process Line

|

Model |

Installed Powder (kw) |

Powder Consumption (kw) |

Output (kg/h) |

Size(L*W*H) (mm) |

|

LY65 |

70kw |

45kw |

120-150kg/h |

20000*1200*2200mm |

|

LY70 |

105kw |

85kw |

200-250kg/h |

22000*1500*2200mm |

|

LY85 |

160kw |

130kw |

300-500kg/h |

25000*2500*2300mm |

|

LY95 |

220kw |

154kw |

800-1000kg/h |

28000*2500*3500mm |

The Advantage Of Pet Feed Process Line

|

Consistent Quality |

A pet feed process line ensures that the pet food products are manufactured to the same high quality standards every time. This consistency helps to build customer loyalty and ensures that pets receive the same high-quality nutrition in every meal. |

|

Increased Efficiency |

A pet feed process line can handle large volumes of raw materials and produce a large quantity of pet food products in a short amount of time. This increased efficiency helps to reduce manufacturing costs and improve profitability. |

|

Nutritional Balance |

A pet feed process line can precisely control the amount and type of ingredients used in the pet food products, ensuring that they meet the nutritional needs of specific pet species. This helps to promote better health and longevity for pets. |

|

Variety Of Products |

A pet feed process line can manufacture a wide variety of pet food products, including dry kibble, wet food, and treats. This variety helps to satisfy the diverse tastes and preferences of pets and their owners. |

|

Regulatory Compliance |

A pet feed process line helps to ensure that pet food products comply with local and international regulatory standards for safety and quality. This compliance helps to build customer trust and ensures that pets receive safe and nutritious food. |

Overall, the advantages of a pet feed process line include consistent quality, increased efficiency, nutritional balance, product variety, and regulatory compliance. These benefits help to ensure that pets receive safe, nutritious, and high-quality food products that meet their specific needs and preferences.

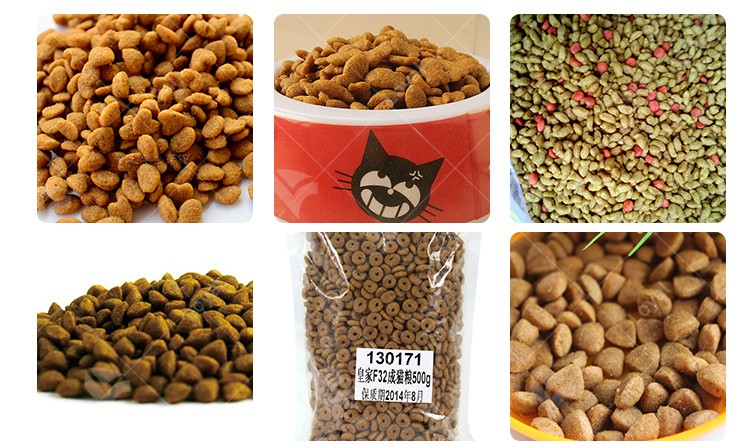

Pet Feed Products Display

Pet feed products are food items that are specifically formulated and marketed for pets, such as dogs, cats, birds, and other small animals. These products come in various forms, including dry kibble, wet canned food, and semi-moist treats.

Pet feed products are designed to provide pets with the nutrients they need to maintain good health and energy levels. They typically contain a balanced blend of proteins, fats, carbohydrates, vitamins, and minerals, as well as other essential nutrients that vary depending on the type of pet and its age, size, and activity level.There are many different brands and types of pet feed products available on the market, each with their own unique formulations and marketing strategies. Some pet owners prefer to feed their pets commercial pet food products, while others prefer to make their own homemade pet food from scratch using natural ingredients.

Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines