- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Company News> The Ultimate Guide to Corn Puff Machine in 2024

The Ultimate Guide to Corn Puff Machine in 2024

2024-04-15 17:01:17Introduction to Corn Puff Machines

Welcome to the ultimate guide to corn puff machines in 2024. As experts in industrial food machinery, it's essential to understand the significance of corn puff machines in the food industry. These machines play a crucial role in the production of various snacks, breakfast cereals, and animal feeds.

Corn puff machines have evolved significantly over the years, incorporating advanced technologies to enhance production efficiency and product quality. These machines utilize different methods such as extrusion, hot air puffing, and microwave heating to transform corn kernels into puffed snacks with desirable texture and flavor.

In this guide, we will explore the different types of corn puff machines, including their operating principles, applications, and advancements in technology. We will also discuss maintenance and troubleshooting tips to ensure optimal performance and safety in corn puff machine operations.

Join us on this journey as we delve deeper into the world of corn puff machines and uncover the secrets behind their success in the food industry.

Overview of the Significance ofcorn puff machines in the Food Industry

Efficiency and Productivity:corn puffing machine are renowned for their efficiency and productivity. They can process large quantities of corn and other ingredients in a relatively short amount of time, making them indispensable in high-volume snack production facilities. With their ability to continuously extrude and shape the dough, corn puffing machine enable seamless and consistent snack production, meeting the demands of today's fast-paced market.

Versatility and Innovation:One of the most remarkable aspects of corn puffing machine is their versatility. These machines can produce a wide variety of snack shapes, sizes, and textures, allowing for endless possibilities in snack innovation. From traditional cheese-flavored puffs to novel shapes and flavors inspired by global cuisines, corn puffing machine empower manufacturers to cater to diverse consumer preferences and market trends.

Quality and Consistency:Consistency is key in the food industry, and corn puffing machine excel in delivering uniformity in snack production. By precisely controlling parameters such as temperature, pressure, and moisture content, these machines ensure that each puff is perfectly cooked and retains its desired texture and flavor profile. This consistency not only enhances the sensory experience for consumers but also reinforces brand reputation and loyalty.

Cost-Effectiveness:In addition to their efficiency and versatility, corn puffing machine offer cost-effectiveness to snack manufacturers. By streamlining the production process and minimizing manual labor, these machines help reduce operational costs and improve overall profitability. Moreover, their long-term reliability and low maintenance requirements make them a smart investment for businesses looking to optimize their production capabilities.

Types of Corn Puffing Machines

Corn puff machines are essential equipment in the food industry, offering versatility and efficiency in snack production. Here, we delve into the various types of corn puff machines available in 2024:

1. Extrusion-Based Corn Puff Machines:

Extrusion-based corn puff machines utilize the process of extrusion to transform raw materials into puffed snacks. A mixture of cornmeal or other grains is fed into the extruder, where it undergoes high pressure and temperature to form a dough-like consistency. As the dough passes through the die, it expands and puffs up, resulting in the characteristic texture of corn puffs. These machines offer high production capacity and versatility in shaping and flavoring options.

2. Hot Air Puffing Machines:

Hot air puffing machines operate by subjecting the raw materials to high-temperature air, causing rapid expansion and puffing. The process involves heating the grains in a sealed chamber and then releasing them into a lower-pressure environment, where they puff up. This method offers a gentler puffing process compared to extrusion, preserving the natural flavors and nutritional value of the ingredients. Hot air puffing machines are commonly used for producing healthier snack alternatives with minimal processing.

3. Microwave Puffing Machines:

Microwave puffing machines utilize microwave energy to heat the raw materials, causing rapid expansion and puffing. The grains are placed in a sealed chamber and exposed to microwave radiation, which generates heat and moisture within the kernels. As the pressure builds up, the grains puff up, resulting in light and crispy snacks. Microwave puffing offers fast and energy-efficient processing, making it suitable for small-scale production and experimental product development.

Each type of corn puff machine has its unique advantages and applications, catering to different production requirements and preferences. Whether it's high-volume extrusion lines for mass production or specialized hot air and microwave puffing systems for niche markets, the variety of options available ensures that manufacturers can find the perfect solution for their snack production needs.

Working Principle of Corn Puffing Machine

The corn puff machine operates on a fascinating principle that transforms raw ingredients into crispy, airy snacks. Let's delve into the intricate workings of this essential piece of industrial food machinery.

At its core, the corn puff machine utilizes a process known as extrusion. This involves forcing a mixture of cornmeal or other grains through a narrow opening under high pressure and temperature. As the mixture passes through the extruder, it undergoes intense heat and pressure, causing it to expand rapidly.

Extrusion Process: During extrusion, the cornmeal mixture is subjected to both mechanical and thermal energy. The high temperature and pressure conditions inside the extruder cause the moisture in the mixture to vaporize, creating steam. The steam acts as a blowing agent, expanding the mixture into a puffed, light texture.

Temperature and Pressure Control:Precise control of temperature and pressure is crucial in the extrusion process. The temperature must be high enough to gelatinize the starches in the cornmeal, allowing for proper expansion and texture development. Meanwhile, the pressure regulates the rate of expansion and ensures uniform puffing across the product.

Die Design:The design of the extrusion die also plays a significant role in determining the final product characteristics. The shape and size of the die openings influence the shape and size of the puffed snacks. Manufacturers can customize the die to produce a wide range of shapes, from traditional balls to unique geometries.

Cooling and Drying:After puffing, the expanded snacks pass through a cooling and drying process to remove excess moisture and set their structure. This step is crucial for achieving the desired texture and shelf stability of the final product.

In summary, the working principle of the corn puff machine revolves around the extrusion process, where a combination of high temperature, pressure, and mechanical forces transforms raw ingredients into delicious, crispy snacks. This innovative technology continues to drive the production of a beloved snack staple in the food industry.

Application of Corn Puffing Machine

As an expert in industrial food machinery, understanding the applications of a corn puff machine is essential. These machines play a pivotal role in the production of a variety of snack foods, breakfast cereals, and even animal feed.

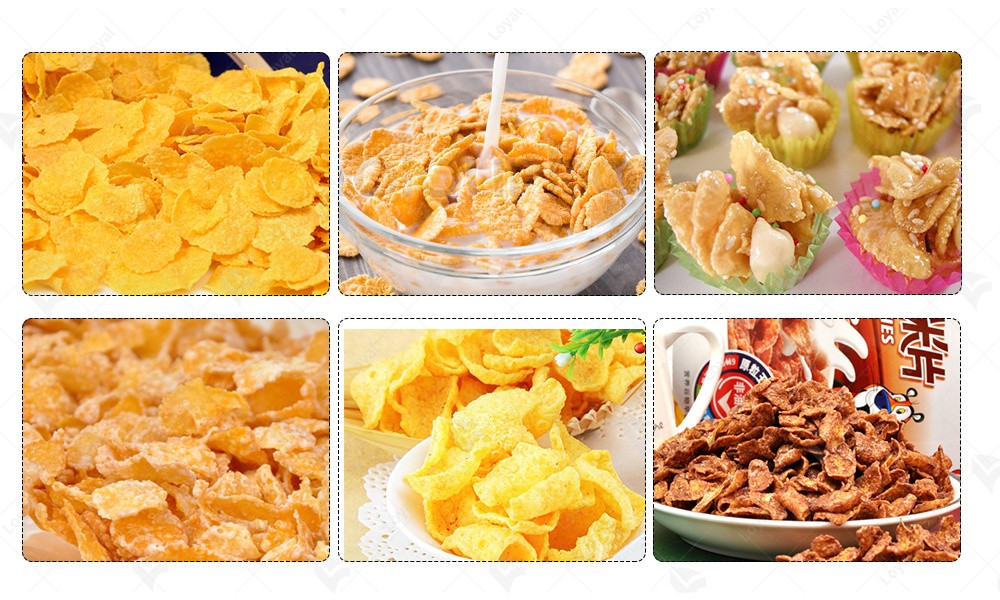

Snack Production: One of the primary applications of a corn puff machine is in snack production. These machines are capable of transforming raw corn kernels into crispy and flavorful corn puffs. By precisely controlling parameters such as temperature, pressure, and moisture content, manufacturers can produce a wide range of snack products with different textures and flavors.

Breakfast Cereals: Corn puffs are also commonly used in the production of breakfast cereals. With a corn puff machine, manufacturers can create a variety of cereal shapes and sizes, from traditional puffed corn flakes to fun and colorful shapes that appeal to children. These cereals are often fortified with vitamins and minerals to enhance their nutritional value.

Animal Feed: In addition to human consumption, corn puffs produced by corn puff machines can also be used as animal feed. The puffing process enhances the digestibility and palatability of corn, making it an ideal feed ingredient for livestock and poultry. By incorporating corn puffs into animal feed formulations, farmers can improve the health and productivity of their animals.

Customization and Innovation: One of the key advantages of corn puff machines is their versatility and flexibility. Manufacturers can customize the shape, size, and flavor of corn puffs to meet the specific preferences of consumers. Additionally, ongoing innovation in corn puff machine technology allows for the development of new and innovative snack products that cater to changing consumer trends and preferences.

In summary, the corn puff machine finds wide-ranging applications in the food industry, from snack production to breakfast cereal manufacturing and animal feed processing. Its versatility, efficiency, and ability to produce high-quality products make it an indispensable tool for food manufacturers seeking to meet the diverse needs of consumers in 2024 and beyond.

Comparison between FEN and LOYAL

|

Aspect |

FEN |

LOYAL |

|

Product Range |

Specializes in commercial fryers, dough mixers, and food processors. |

Offers a wide range of food processing equipment, including fryers, ovens, mixers, and packaging machines. |

|

Technology |

Incorporates advanced technology to enhance efficiency and precision in food processing. |

Known for innovative technological solutions, such as automation and digitalization, to optimize production processes. |

|

Quality |

Renowned for high-quality, durable equipment built to withstand rigorous industrial use. |

Prioritizes quality craftsmanship and materials to deliver reliable and long-lasting machinery. |

|

Customer Support |

Provides comprehensive customer support services, including installation, training, and maintenance. |

Offers dedicated customer service and technical assistance to ensure optimal performance and satisfaction. |

|

Customization |

Offers customization options to tailor equipment to specific client requirements and production needs. |

Provides flexible customization services to accommodate unique production processes and facility layouts. |

|

Industry Presence |

Well-established presence in the commercial kitchen equipment sector, serving restaurants, hotels, and foodservice establishments. |

Recognized as a leading supplier of food processing machinery to industrial-scale food manufacturers and processors. |

|

Innovation |

Continuously invests in research and development to introduce new features and improve equipment performance. |

Drives innovation through collaboration with industry partners and investment in cutting-edge technologies. |

|

Sustainability |

Committed to sustainable practices, including energy-efficient designs and eco-friendly materials. |

Integrates sustainability into product design and manufacturing processes to minimize environmental impact. |

Advances in Corn Puffing Machine Technology

As we delve into the realm of corn puff machine technology in 2024, significant advancements have been made to enhance efficiency, productivity, and product quality.

Extrusion-Based Systems: One of the notable advancements lies in extrusion-based corn puff machines. Manufacturers have integrated advanced control systems and sensors to precisely regulate process parameters such as temperature, pressure, and moisture content. This level of control ensures consistent puffing results and minimizes product variations.

Automation and Digitalization: Another key development is the increased automation and digitalization of corn puff machine operations. Automated feeding systems, continuous monitoring sensors, and data analytics capabilities have streamlined production processes and improved overall efficiency. Operators can now monitor and adjust machine settings in real-time, optimizing production outcomes and reducing downtime.

Smart Sensors and AI Integration: The integration of smart sensors and artificial intelligence (AI) algorithms has revolutionized corn puff machine technology. Smart sensors detect variations in raw material characteristics and environmental conditions, allowing for real-time adjustments to optimize puffing performance. AI algorithms analyze data patterns to predict equipment maintenance needs, preventing unexpected breakdowns and ensuring uninterrupted production.

Energy Efficiency: In response to growing environmental concerns, manufacturers have prioritized energy-efficient designs in corn puff machines. Innovations such as heat recovery systems, improved insulation, and energy-efficient motors have reduced energy consumption while maintaining high production rates. This not only lowers operational costs but also contributes to sustainability efforts.

Future Outlook: Looking ahead, the future of corn puff machine technology appears promising. Continued research and development efforts are expected to further enhance automation, precision, and sustainability in puffing operations. Integration with Industry 4.0 principles, such as the Internet of Things (IoT) and big data analytics, will unlock new possibilities for optimization and innovation in the years to come.

In conclusion, the advancements in corn puff machine technology in 2024 signify a shift towards smarter, more efficient, and sustainable puffing solutions. By embracing these innovations, manufacturers can stay ahead of the curve and meet the evolving demands of the food industry.

Maintenance and Troubleshooting of Corn Puffing Machine

Maintaining and troubleshooting a corn puff machine is essential to ensure consistent performance and product quality. As an expert in industrial food machinery, it's crucial to understand the key maintenance tasks and troubleshooting techniques for these machines.

Regular Cleaning:Proper cleaning of the corn puff machine is vital to prevent buildup of residue and ensure hygienic production. Regularly clean all components of the machine, including the extruder, dryer, and conveyor belts, using food-grade cleaning agents. Pay special attention to areas prone to residue buildup, such as nozzles and vents.

Lubrication:Regular lubrication of moving parts is necessary to reduce friction and prevent premature wear. Apply lubricant to bearings, gears, and other moving components according to the manufacturer's recommendations. Check lubrication levels regularly and replenish as needed to ensure smooth operation.

Inspection and Maintenance:Regular inspection of the corn puff machine is crucial to identify potential issues early and prevent breakdowns. Inspect all components for signs of wear, damage, or misalignment, and replace any worn or damaged parts promptly. Additionally, schedule periodic maintenance tasks such as belt tension adjustment and motor alignment to optimize performance.

Temperature and Pressure Control:Monitoring and controlling temperature and pressure are critical aspects of maintaining product quality and safety in corn puff production. Regularly calibrate temperature and pressure sensors, and adjust settings as needed to ensure consistency and adherence to production standards.

Troubleshooting Common Issues

Despite regular maintenance, corn puff machines may encounter common issues that require troubleshooting:

- Uneven Puffing: If corn puffs are coming out unevenly sized, check for blockages in the extruder or inconsistent pressure settings. Clear any blockages and adjust pressure settings accordingly.

- Excessive Breakage: Excessive breakage of corn puffs may indicate issues with the cutting mechanism or conveyor belts. Inspect these components for damage or misalignment and make necessary adjustments or replacements.

- Quality Variations: Variations in puff quality could be due to fluctuations in temperature or moisture levels. Check and adjust temperature and moisture settings to achieve the desired puff texture.

Safety Precautions for Operating Corn Puff Machine

As experts in industrial food machinery, ensuring the safety of operators and maintaining a secure working environment is paramount when operating a corn puff machine. Here are some essential safety precautions to follow:

1. Training and Education: Before operating a corn puff machine, ensure that all operators undergo comprehensive training on its operation, including safety protocols and emergency procedures. This training should cover topics such as machine controls, hazards awareness, and proper use of personal protective equipment (PPE).

2. Machine Inspection: Prior to starting the machine, conduct a thorough inspection to ensure that all components are in good working condition. Check for loose or damaged parts, leaks, and any other potential hazards. Address any issues promptly before proceeding with operation.

3. Personal Protective Equipment (PPE): Provide operators with appropriate PPE, including safety glasses, gloves, and hearing protection, to minimize the risk of injury from flying debris, hot surfaces, or loud noise generated during operation.

4. Operating Procedures: Follow established operating procedures provided by the manufacturer. This includes proper startup and shutdown procedures, as well as guidelines for adjusting machine settings and handling materials safely.

5. Machine Guarding: Ensure that all moving parts of the corn puff machine are properly guarded to prevent accidental contact. Guards should be in place for exposed belts, chains, and rotating components to prevent entanglement or crushing injuries.

6. Hot Surfaces: Be cautious of hot surfaces, such as heating elements and cooking chambers, which can cause burns. Avoid touching hot surfaces and use insulated gloves or tools when necessary.

7. Emergency Stop: Familiarize operators with the location and operation of the emergency stop button or switch. In the event of an emergency or malfunction, operators should know how to quickly shut down the machine to prevent further risks.

8. Fire Safety: Take precautions to prevent fires, such as keeping flammable materials away from heat sources and maintaining a clean work area. Have fire extinguishers readily available and ensure that operators are trained in their proper use.

9. Regular Maintenance: Schedule regular maintenance and inspections of the corn puff machine to ensure its continued safe operation. This includes cleaning, lubricating moving parts, and replacing worn components as needed.

Reference materials

Here are some authoritative foreign websites for industrial food machinery-related literature references, along with their URLs:

1. Food Engineering Magazine

Website: [https://www.foodengineeringmag.com/]

2. Food Processing Magazine

Website: [https://www.foodprocessing.com/]

3. Institute of Food Technologists (IFT)

Website: [https://www.ift.org/]

4. American Society of Agricultural and Biological Engineers (ASABE)

Website: [https://www.asabe.org/]

5. European Federation of Food Science and Technology (EFFoST)

Website: [https://effost.org/]

These websites provide a wide range of information related to industrial food machinery, including the latest industry news, research findings, and technological trends, making them valuable resources for authoritative references and academic research.

Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines