- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Company News> Everything you need to know about small biscuit making machine In 2024

Everything you need to know about small biscuit making machine In 2024

2024-04-25 16:29:09Introduction

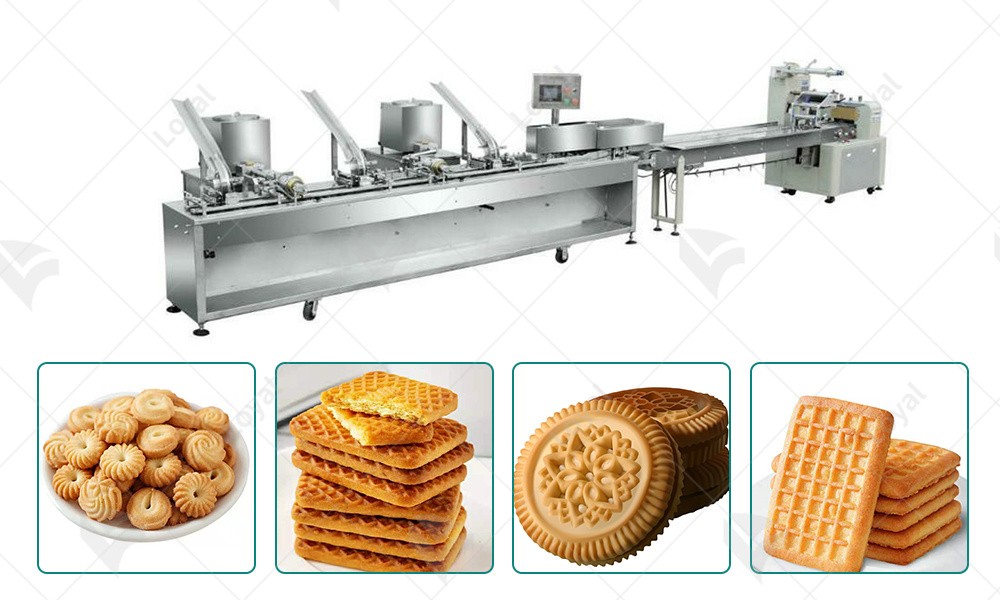

Small biscuit making machines represent a pivotal advancement in the realm of food machinery, catering to the needs of businesses aiming for streamlined biscuit production on a smaller scale. These compact yet efficient machines have revolutionized the way biscuits are manufactured, offering a blend of precision engineering and automation to meet the demands of small-scale bakeries, startups, and niche businesses. By incorporating cutting-edge technology and innovative design, small biscuit making machines enable operators to achieve consistent quality and output while minimizing manual labor and maximizing efficiency.

In recent years, the market for small biscuit making machines has witnessed significant growth, driven by the increasing popularity of artisanal biscuits, specialty cookies, and personalized treats. Unlike their larger counterparts, these machines are specifically tailored to suit the needs of smaller operations, offering a more affordable and space-efficient solution for businesses looking to enter the biscuit manufacturing market or expand their product offerings. With their compact footprint and user-friendly interfaces, small biscuit making machines have democratized biscuit production, empowering entrepreneurs and small-scale producers to enter the market with confidence and compete on a level playing field with larger manufacturers.

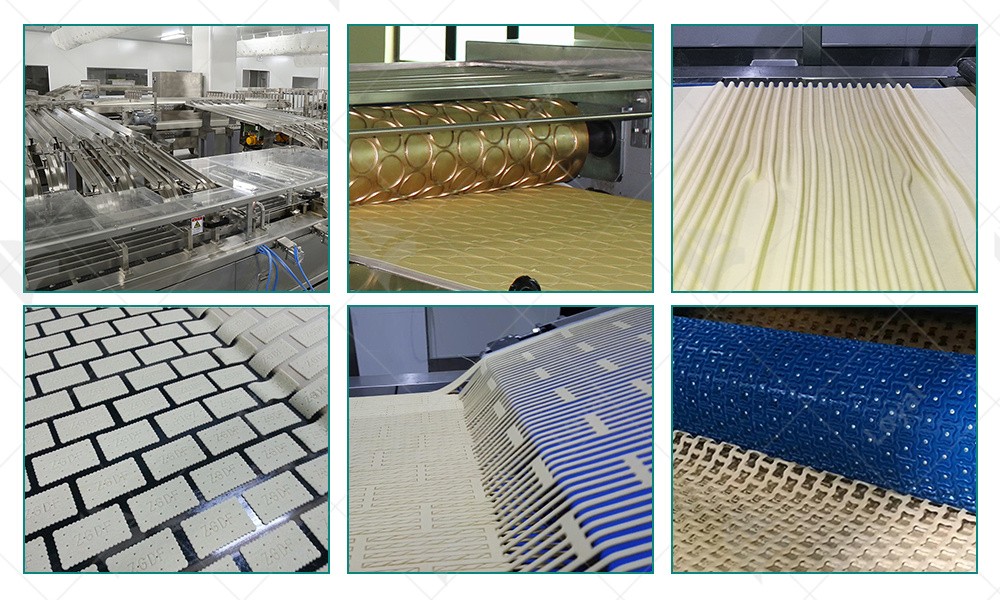

Key Features and Components

|

Component |

Description |

|

Dough Mixers |

These machines are responsible for mixing the dough ingredients thoroughly to achieve the desired consistency. |

|

Dough Sheeting Rollers |

Dough sheeters roll out the dough into thin sheets of uniform thickness, ready for cutting and forming. |

|

Biscuit Cutting Units |

Equipped with various cutting blades, these units precisely cut the dough into biscuit shapes as per requirements. |

|

Baking Ovens |

Biscuit baking ovens bake the shaped dough into biscuits, ensuring even heat distribution for consistent results. |

|

Cooling Conveyors |

Cooling conveyors transport freshly baked biscuits to cool down before packaging, preventing overheating and damage. |

Small biscuit making machines typically consist of these key components, each playing a crucial role in the automated production process. These components work in harmony to transform raw ingredients into finished biscuits efficiently and consistently.

Advantages and Benefits

Small biscuit making machines offer a plethora of advantages and benefits to businesses in the food industry, revolutionizing biscuit production on a smaller scale:

1. Increased Efficiency: These machines streamline the biscuit-making process, reducing the need for manual labor and increasing production efficiency. By automating various stages of production, they enable businesses to produce a higher volume of biscuits in less time.

2. Consistent Product Quality: Small biscuit making machines ensure consistency in the quality and characteristics of the biscuits produced. Through precise control of ingredients, shaping, and baking processes, they deliver biscuits with uniform taste, texture, and appearance, enhancing consumer satisfaction and brand reputation.

3. Cost-Effectiveness: While the initial investment in small biscuit making machines may seem significant, they offer long-term cost savings through reduced labor costs, increased productivity, and minimized wastage. By optimizing resources and minimizing downtime, these machines contribute to improved profitability for businesses.

4. Versatility: Small biscuit making machines are versatile and adaptable, capable of producing a wide range of biscuit varieties, shapes, and sizes. This versatility allows businesses to cater to diverse consumer preferences and market demands, expanding their product offerings and market reach.

5. Space Efficiency: Designed with a compact footprint, small biscuit making machines are space-efficient, making them suitable for small-scale bakeries, startups, and businesses with limited space. They enable businesses to maximize the use of available space while maintaining efficient biscuit production.

Overall, small biscuit making machines offer a host of advantages that empower businesses to streamline production, improve product quality, and meet the demands of today's dynamic market landscape.

Applications and Industries

Small biscuit making machines find extensive applications across various industries within the food manufacturing sector, catering to the diverse needs of businesses and consumers alike. Some of the key applications and industries where these machines are widely utilized include:

1. Bakery Industry: Small biscuit making machines are a cornerstone of the bakery industry, enabling bakeries of all sizes to produce high-quality biscuits, cookies, and crackers. From artisanal bakeries to large-scale commercial bakeries, these machines play a crucial role in meeting consumer demand for freshly baked goods.

2. Confectionery Industry: In the confectionery sector, small biscuit making machines are utilized to produce a wide range of confectionery products that incorporate biscuits as an ingredient. These include sandwich biscuits, cream-filled biscuits, and chocolate-coated biscuits, among others, adding diversity to the confectionery product lineup.

3. Food Service and Hospitality: Small biscuit making machines are also utilized in the food service and hospitality industry to produce biscuits and cookies for restaurants, cafes, hotels, and catering businesses. These machines enable food service establishments to offer freshly baked biscuits as part of their menu offerings, enhancing customer satisfaction and dining experience.

4. Specialty and Artisanal Food Producers: Small biscuit making machines are particularly popular among specialty and artisanal food producers who focus on crafting unique and premium-quality biscuits. These producers leverage small biscuit making machines to create handcrafted biscuits with distinctive flavors, textures, and shapes, catering to niche markets and discerning consumers.

5. Startups and Small-Scale Businesses: Small biscuit making machines are instrumental for startups and small-scale businesses looking to enter the biscuit manufacturing market or expand their product offerings. With their affordability, compact size, and ease of use, these machines provide aspiring entrepreneurs with a cost-effective solution to kickstart their biscuit production venture.

Overall, small biscuit making machines serve as indispensable tools across a wide range of industries within the food manufacturing sector, facilitating efficient and consistent biscuit production to meet the diverse needs of consumers in today's market.

Considerations for Choosing a Small Biscuit Making Machine

When selecting a small biscuit making machine for your business, several essential factors should be taken into consideration to ensure that you make the right choice:

1. Production Capacity: Assess the production capacity of the machine and ensure that it aligns with your business requirements. Consider factors such as the number of biscuits produced per hour and the machine's ability to meet peak production demands.

2. Space Requirements: Evaluate the available space in your production facility and choose a machine that fits comfortably within your layout. Opt for a compact and space-efficient design that maximizes floor space utilization without compromising on performance.

3. Versatility and Flexibility: Look for a machine that offers versatility in biscuit shapes, sizes, and types. Ensure that it can accommodate various recipes and production requirements, allowing you to diversify your product offerings and cater to changing consumer preferences.

4. Ease of Operation: Choose a machine that is user-friendly and easy to operate, with intuitive controls and interfaces. Ensure that your staff receive adequate training on machine operation to maximize efficiency and minimize downtime.

5. Maintenance Requirements: Consider the maintenance needs of the machine and opt for a model that is easy to clean, maintain, and service. Choose a machine with accessible components and spare parts availability to facilitate timely repairs and prevent disruptions to production.

6. Energy Efficiency: Select a machine that is energy-efficient and environmentally friendly, with features such as energy-saving modes and efficient heating systems. This will help reduce your overall operating costs and minimize your environmental footprint.

7. Safety Features: Prioritize machine safety and choose a model that is equipped with essential safety features, such as emergency stop buttons, safety guards, and automatic shutdown mechanisms. Ensure compliance with industry safety standards to protect your employees and prevent accidents.

8. Cost Considerations: Evaluate the overall cost of the machine, including upfront purchase costs, ongoing maintenance expenses, and potential returns on investment. Choose a machine that offers the best value for money while meeting your production needs and quality standards.

By carefully considering these factors and conducting thorough research, you can select the right small biscuit making machine for your business, ensuring optimal performance, efficiency, and profitability in biscuit production operations.

Maintenance and Care

Proper maintenance and care are essential aspects of ensuring the longevity, efficiency, and safety of small biscuit making machines. Here are some key considerations for maintaining and caring for these machines:

1. Regular Cleaning: Develop a cleaning schedule to ensure that the machine is cleaned regularly, both internally and externally. Remove any dough residues, crumbs, or debris that may accumulate on the machine's surfaces, rollers, and cutting blades. Use food-grade cleaning agents and sanitizers to maintain hygiene standards.

2. Lubrication: Keep the moving parts of the machine well-lubricated to prevent friction and wear. Apply lubricants to bearings, gears, and other critical components as per the manufacturer's recommendations. Regular lubrication helps reduce friction, noise, and heat generation, ensuring smooth operation and prolonging the machine's lifespan.

3. Inspection and Maintenance Checks: Conduct routine inspections and maintenance checks to identify any signs of wear, damage, or malfunction. Inspect belts, chains, motors, and electrical connections for signs of wear or damage. Replace worn or damaged parts promptly to prevent further deterioration and avoid unexpected breakdowns during production.

4. Calibration and Adjustment: Periodically calibrate and adjust the machine to ensure accurate dough processing, shaping, and cutting. Check the alignment of rollers, cutting blades, and other components to maintain precision and consistency in biscuit production. Make any necessary adjustments to optimize the machine's performance and product quality.

5. Temperature Control: Monitor and control the temperature settings of the machine's baking oven to ensure consistent baking results. Regularly calibrate temperature sensors and heating elements to maintain accurate temperature control throughout the baking process. This helps prevent underbaked or overbaked biscuits and ensures uniform product quality.

6. Operator Training: Provide comprehensive training to machine operators on proper operation, maintenance, and safety procedures. Ensure that operators are familiar with the machine's controls, features, and maintenance requirements. Encourage a culture of responsibility and accountability for machine care and maintenance among your staff.

7. Documentation and Records: Keep detailed records of maintenance activities, repairs, and inspections performed on the machine. Maintain a logbook or digital records to track maintenance schedules, spare parts replacements, and any issues encountered. This documentation helps ensure compliance with regulatory requirements and facilitates troubleshooting in case of problems.

By implementing a proactive maintenance and care regimen for small biscuit making machines, businesses can minimize downtime, optimize production efficiency, and extend the lifespan of their equipment. Regular maintenance not only ensures consistent product quality but also enhances workplace safety and operational reliability.

Technological Advancements

In recent years, technological advancements have significantly transformed the landscape of small biscuit making machines, introducing innovative features and capabilities that enhance efficiency, productivity, and quality. Here are some notable technological advancements in this field:

1. Automation and Robotics: Modern small biscuit making machines increasingly incorporate automation and robotics technology to streamline production processes and minimize manual intervention. Automated dough mixing, shaping, cutting, and packaging systems improve consistency, accuracy, and efficiency while reducing labor costs and human error.

2. Smart Controls and Monitoring Systems: Advanced control systems equipped with intelligent sensors and monitoring devices enable real-time tracking and optimization of machine performance. These systems offer precise control over variables such as dough consistency, temperature, speed, and pressure, ensuring consistent product quality and minimizing waste.

3. Energy Efficiency Solutions: Manufacturers are integrating energy-efficient components and technologies into small biscuit making machines to reduce energy consumption and environmental impact. Energy-saving features such as efficient heating elements, insulation, and power management systems help minimize energy wastage and lower operating costs.

4. Digitalization and Connectivity: Small biscuit making machines are becoming increasingly interconnected through digitalization and connectivity features. Integration with Industry 4.0 technologies allows for remote monitoring, predictive maintenance, and data-driven optimization of production processes. Real-time data analytics enable proactive decision-making and performance improvement.

5. Customization and Flexibility: Advancements in machine design and engineering allow for greater customization and flexibility in small biscuit making machines. Modular designs and interchangeable components facilitate quick changeovers between different biscuit types, shapes, and sizes, enabling businesses to adapt to changing market demands and consumer preferences with ease.

6. Hygiene and Sanitation Solutions: With a growing focus on food safety and hygiene, manufacturers are incorporating advanced sanitation features into small biscuit making machines. Easy-to-clean surfaces, sanitary design principles, and antimicrobial materials help minimize the risk of contamination and ensure compliance with stringent food safety standards.

7. Augmented Reality (AR) and Virtual Reality (VR): AR and VR technologies are being utilized for training purposes, allowing operators to simulate machine operation, maintenance procedures, and troubleshooting scenarios in a virtual environment. This immersive training experience enhances operator proficiency, reduces training time, and improves overall equipment utilization.

These technological advancements represent a paradigm shift in the small biscuit making machine industry, driving innovation, efficiency, and competitiveness. Businesses that embrace these technologies stand to gain a competitive edge by improving production capabilities, product quality, and operational sustainability in the dynamic landscape of biscuit manufacturing.

Market Trends and Outlook

In today's rapidly evolving food industry, small biscuit making machines are experiencing a surge in demand driven by several key market trends and factors. These trends shape the outlook for the small biscuit making machine market and influence the strategies of manufacturers, suppliers, and stakeholders.

1. Rising Consumer Demand for Convenience Foods: With hectic lifestyles and increasing urbanization, consumers are seeking convenient and ready-to-eat food options, including biscuits and cookies. Small biscuit making machines cater to this demand by enabling businesses to produce a wide range of biscuits quickly and efficiently, meeting consumer preferences for convenience and variety.

2. Growing Emphasis on Health and Wellness: In response to rising health consciousness among consumers, there is a growing demand for healthier biscuit options made with natural ingredients, whole grains, and reduced sugar and fat content. Small biscuit making machines equipped with customizable settings and recipe formulations allow businesses to produce healthier biscuit alternatives to meet evolving consumer preferences.

3. Market Expansion in Emerging Economies: Emerging economies in Asia-Pacific, Latin America, and Africa are witnessing rapid urbanization, changing dietary habits, and increasing disposable incomes, driving the demand for biscuits and other baked goods. Small biscuit making machines offer cost-effective solutions for local bakeries, startups, and entrepreneurs in these regions to enter the biscuit manufacturing market and capitalize on growing consumer demand.

4. Technological Advancements and Innovation: Ongoing technological advancements in small biscuit making machines, such as automation, digitalization, and smart controls, are enabling manufacturers to improve machine performance, efficiency, and versatility. Innovations in machine design, materials, and processes enhance product quality, reduce production costs, and drive market competitiveness.

5. Sustainability and Environmental Concerns: With growing awareness of environmental issues and sustainability, there is a shift towards eco-friendly manufacturing practices and packaging solutions in the food industry. Small biscuit making machines that incorporate energy-efficient components, waste reduction measures, and recyclable materials align with these sustainability goals, attracting environmentally conscious consumers and businesses.

6. Market Consolidation and Competitive Landscape: The small biscuit making machine market is witnessing consolidation as larger manufacturers acquire smaller players to expand their product portfolios and global reach. Intensifying competition among manufacturers is driving innovation, price competitiveness, and market differentiation, benefiting consumers with a wider range of choices and improved product offerings.

7. Regulatory Compliance and Food Safety Standards: Stringent regulatory requirements and food safety standards govern the manufacturing and distribution of biscuits and baked goods worldwide. Small biscuit making machines must adhere to these regulations, ensuring product safety, quality, and compliance with labeling and packaging requirements to maintain consumer trust and confidence.

Overall, the small biscuit making machine market is poised for continued growth and innovation as it adapts to evolving consumer preferences, technological advancements, and market dynamics. Businesses that stay abreast of these trends and invest in innovative solutions will be well-positioned to capitalize on emerging opportunities and drive success in the dynamic biscuit manufacturing industry.

Conclusion

In conclusion, the landscape of small biscuit making machines is evolving rapidly, driven by technological advancements, changing consumer preferences, and industry dynamics. As highlighted in this guide, these machines play a pivotal role in the biscuit manufacturing process, enabling businesses to produce a wide range of biscuits efficiently and effectively. From the versatility of biscuit varieties to the importance of maintenance and care, each aspect contributes to the overall success and competitiveness of biscuit production.

Looking ahead, the future of small biscuit making machines appears promising, with opportunities for growth and innovation abound. Market trends such as rising consumer demand for convenience foods, growing emphasis on health and wellness, and technological advancements in automation and connectivity are reshaping the industry landscape. However, challenges such as sustainability concerns, skills shortages, and regulatory compliance requirements must be addressed to ensure sustainable growth and competitiveness.

Ultimately, businesses that embrace these trends, invest in technological innovation, prioritize sustainability initiatives, and uphold quality and safety standards will be well-positioned to thrive in the dynamic biscuit manufacturing industry. By staying agile, adaptive, and customer-focused, manufacturers of small biscuit making machines can capitalize on emerging opportunities, drive innovation, and shape the future of biscuit production in 2024 and beyond.

Reference

1. Food Processing:

Website: [Food Processing](https://www.foodprocessing.com/)

2. Food Engineering:

Website: [Food Engineering](https://www.foodengineeringmag.com/)

3. Process Industry Forum:

Website: [Process Industry Forum](https://www.processindustryforum.com/)

4. Food Manufacture:

Website: [Food Manufacture](https://www.foodmanufacture.co.uk/)

Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines