- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Company News> The Ultimate Breakfast Cereal Machine Factory Guide to 2024

The Ultimate Breakfast Cereal Machine Factory Guide to 2024

2024-07-02 10:20:35Introduction to Breakfast Cereal Machine Factories

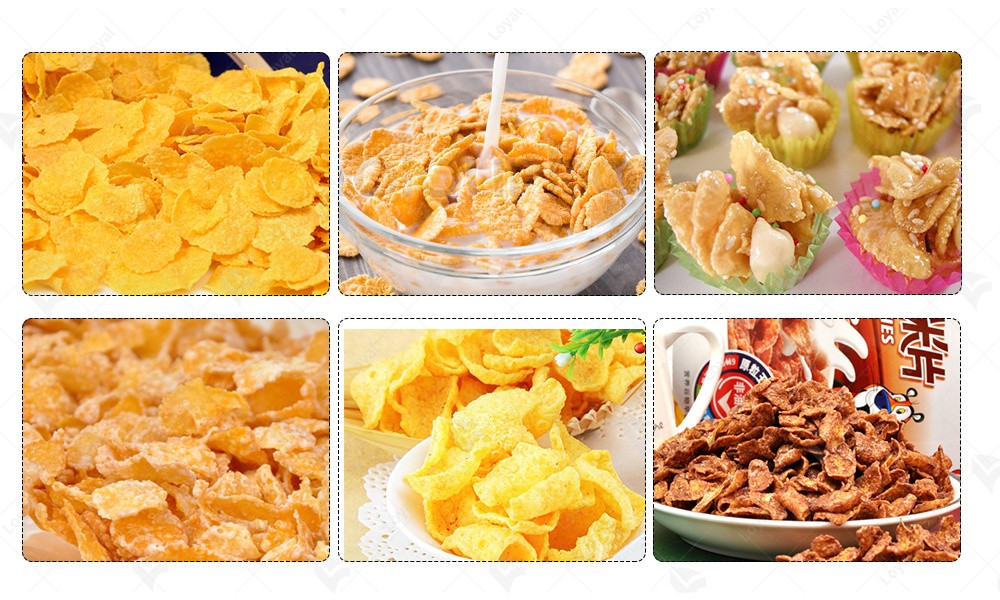

Breakfast cereal machine factories play a crucial role in the food industry, specializing in the production of machinery designed to manufacture various types of breakfast cereals. These factories are equipped with advanced technology and equipment that ensure efficient and consistent production processes. The importance of these factories cannot be overstated, as they provide the backbone for producing high-quality breakfast cereals that meet consumer demand worldwide. Understanding the intricacies of these factories can offer valuable insights into the broader industrial food machinery sector.

One of the key aspects of a breakfast cereal machine factory is its focus on innovation and technological advancement. These factories are constantly evolving to incorporate the latest advancements in food processing technology. This includes the development of new machinery that can produce cereals more efficiently, with better quality control and lower production costs. The drive for innovation is fueled by the need to meet changing consumer preferences and to stay competitive in the market. As a result, breakfast cereal machine factories are at the forefront of technological progress in the food industry.

The production process in a breakfast cereal machine factory involves several stages, each requiring specialized machinery. From raw material handling and mixing to cooking, shaping, and packaging, every step is carefully controlled to ensure the final product meets the highest standards. Key components of these production lines include mixers, extruders, dryers, and packaging machines. Each piece of equipment is designed to perform a specific function, and together they create a seamless production line capable of producing large quantities of breakfast cereal efficiently.

Quality control is another critical aspect of breakfast cereal machine factories. Ensuring that each batch of cereal meets stringent quality standards is essential for maintaining consumer trust and satisfaction. These factories implement rigorous quality control measures at every stage of the production process. This includes regular inspections, testing of raw materials, and monitoring of production parameters. By maintaining high-quality standards, breakfast cereal machine factories can produce cereals that are not only tasty but also safe and nutritious for consumers.

Breakfast cereal machine factories are integral to the food industry, providing the machinery needed to produce a wide range of breakfast cereals. These factories are characterized by their focus on innovation, advanced production processes, and stringent quality control measures. As the demand for breakfast cereals continues to grow, the role of breakfast cereal machine factories will become even more important. By understanding how these factories operate, one can gain a deeper appreciation for the complexity and sophistication of the industrial food machinery sector.

Latest Innovations in Breakfast Cereal Machinery

In recent years, significant advancements have been made in breakfast cereal machinery, enhancing efficiency and product quality across manufacturing processes. These innovations cater to the evolving demands of the breakfast cereal industry, aiming to improve production capabilities while maintaining high standards of food safety and sustainability.

Breakfast cereal machine factories are increasingly adopting advanced automation technologies. Robotic arms and automated packaging systems streamline production lines, reducing manual labor and optimizing workflow. This integration not only enhances operational efficiency but also ensures consistent product quality, meeting the stringent requirements of modern consumers.

The incorporation of Internet of Things (IoT) devices and data analytics has revolutionized breakfast cereal manufacturing. Sensors embedded in machinery monitor key parameters such as temperature, moisture levels, and production speed in real-time. This data is analyzed to predict maintenance needs, optimize production schedules, and minimize downtime, thereby improving overall equipment effectiveness (OEE).

To accommodate diverse consumer preferences and market trends, manufacturers are developing modular and flexible production lines. These systems allow quick reconfiguration for producing different cereal varieties and packaging formats without extensive downtime. Such flexibility enables factories to respond promptly to changing market demands and maintain competitive edge in the industry.

In response to growing environmental concerns, breakfast cereal machine factories are focusing on sustainable packaging solutions. Innovations include biodegradable packaging materials, reduced packaging waste through optimized design, and eco-friendly packaging processes. These initiatives not only appeal to environmentally conscious consumers but also align with regulatory requirements for sustainable business practices.

These innovations in breakfast cereal machinery underscore the industry's commitment to technological advancement, operational efficiency, and sustainability. By integrating automation, IoT, flexible production lines, and sustainable practices, breakfast cereal machine factories are poised to meet the challenges of the future while delivering high-quality products to global markets.

Key Components of Breakfast Cereal Production Lines

|

Component |

Description |

|

Raw Material Handling Systems |

Systems for handling grains, including cleaning, storage, and distribution. |

|

Mixing and Blending Equipment |

Machines for mixing grains, additives, and flavorings uniformly. |

|

Extrusion Systems |

Equipment for shaping cereal dough into specific forms via extrusion. |

|

Drying and Toasting Systems |

Systems for drying and toasting cereal products to achieve desired texture. |

|

Coating and Flavoring Systems |

Machines for applying coatings and flavorings to finished cereal products. |

|

Packaging Systems |

Equipment for packaging cereals into various formats (boxes, bags, etc.). |

|

Quality Control Systems |

Systems for monitoring and ensuring product quality throughout production. |

|

Automation and Control Systems |

Control systems to regulate and optimize production processes automatically. |

|

Cleaning and Sanitation Systems |

Systems for cleaning and maintaining equipment to meet hygiene standards. |

|

Waste Management Systems |

Systems for managing and minimizing waste generated during production. |

Quality Control and Safety Standards in Cereal Manufacturing

Quality control and safety standards in cereal manufacturing are paramount to ensuring product consistency and consumer safety within a Breakfast Cereal Machine Factory. These standards encompass rigorous protocols and systematic checks throughout the production process to maintain high-quality standards and mitigate potential risks.

Firstly, quality control begins with raw materials inspection and testing. Suppliers of grains and additives undergo stringent quality assessments to guarantee they meet specified standards for purity and nutritional content. This initial step ensures that only premium ingredients enter the production line, aligning with the factory's commitment to excellence in cereal manufacturing.

Once ingredients are approved for use, the production process itself undergoes meticulous monitoring. Advanced sensors and automated systems within the cereal machines continuously monitor parameters such as temperature, moisture levels, and mixing times. These measures ensure consistency in product texture, flavor, and nutritional content batch after batch, reinforcing the factory's adherence to quality benchmarks.

Furthermore, adherence to safety standards is non-negotiable in cereal manufacturing. The factory implements comprehensive safety protocols to safeguard both equipment operators and consumers. This includes regular maintenance of machinery to prevent mechanical failures that could compromise product quality or pose safety hazards. Additionally, stringent hygiene practices and sanitation procedures are strictly enforced to prevent cross-contamination and maintain a sterile manufacturing environment.

Maintaining rigorous quality control and safety standards is not only a regulatory requirement but also a cornerstone of operational excellence for a Breakfast Cereal Machine Factory. By adhering to these standards, the factory ensures consistent product quality, consumer trust, and operational efficiency in the competitive cereal manufacturing industry.

Energy Efficiency and Sustainability in Cereal Production

Energy efficiency and sustainability are crucial considerations in the operation of a Breakfast Cereal Machine Factory. Modern cereal production lines integrate advanced technologies aimed at minimizing energy consumption while maximizing output. These machines are designed to optimize processes such as mixing, extrusion, and drying, thereby reducing overall energy usage per unit of cereal produced. Implementing energy-efficient practices not only lowers operational costs but also aligns with global sustainability goals, reducing carbon footprints associated with cereal manufacturing.

Breakfast Cereal Machine Factories often employ state-of-the-art equipment equipped with energy-saving features like automated shutdown during idle times and energy recovery systems. These technologies ensure that energy is utilized efficiently throughout the production process, contributing to lower operational costs and reduced environmental impact. Moreover, sustainable practices extend beyond energy efficiency to encompass resource management, waste reduction, and eco-friendly packaging solutions, ensuring a holistic approach to environmental stewardship in cereal production.

Adherence to sustainability standards in Breakfast Cereal Machine Factories involves continuous monitoring and improvement of production processes. Manufacturers prioritize the use of renewable energy sources and eco-friendly materials in machine construction and operation. By integrating these sustainable practices into their operations, cereal manufacturers can enhance their market competitiveness while meeting consumer demand for environmentally responsible products. This commitment not only supports corporate social responsibility but also fosters long-term viability in the competitive breakfast cereal market.

Energy efficiency and sustainability are integral to the operations of Breakfast Cereal Machine Factories, driven by innovative technologies and sustainable practices. By focusing on reducing energy consumption, optimizing resource utilization, and adopting eco-friendly solutions, these factories can achieve both economic benefits and environmental stewardship. Embracing these principles ensures that Breakfast Cereal Machine Factories remain at the forefront of sustainable food production, meeting the challenges of today while preparing for the demands of tomorrow.

Regulatory Compliance for Breakfast Cereal Manufacturers

To ensure compliance with regulatory standards is crucial for Breakfast Cereal Machine Factories. Regulatory bodies enforce guidelines to ensure safety, quality, and consistency in food production processes. Manufacturers must adhere to these regulations to operate legally and maintain consumer trust.

Regulatory compliance for Breakfast Cereal Manufacturers involves meeting standards set by food safety authorities. These regulations cover aspects such as hygiene practices, ingredient sourcing, and production processes. Ensuring compliance requires thorough documentation of processes and regular inspections to verify adherence to standards.

Implementing regulatory compliance measures involves establishing robust quality control systems within the Breakfast Cereal Machine Factory. This includes conducting regular audits and inspections to identify and rectify any deviations from regulatory requirements promptly. Compliance also extends to labeling laws, ensuring accurate and informative product labels that meet regulatory specifications.

Failure to comply with regulatory standards can result in fines, product recalls, or even closure of the Breakfast Cereal Machine Factory. Therefore, manufacturers must stay updated with evolving regulations and adjust their operations accordingly to maintain compliance and ensure consumer safety.

Regulatory compliance is a cornerstone of operating a Breakfast Cereal Machine Factory. By adhering to established standards and implementing rigorous quality control measures, manufacturers can ensure the safety, quality, and legality of their cereal products, thus safeguarding both consumer trust and operational continuity.

Trends and Predictions for the Breakfast Cereal Industry in 2024

In 2024, the Breakfast Cereal Machine Factory sector is poised for significant advancements and shifts. Manufacturers are increasingly focusing on integrating smart technologies into their production lines to enhance efficiency and quality control. These technologies include IoT-enabled sensors that monitor production processes in real-time, ensuring consistent product quality and reducing downtime. Moreover, there's a growing trend towards modular and flexible cereal production equipment, allowing manufacturers to quickly adapt to changing consumer demands and market trends.

Looking ahead, sustainability will continue to be a key driver in the Breakfast Cereal Machine Factory industry. Manufacturers are expected to invest more in eco-friendly production methods and materials, responding to consumer preferences for environmentally responsible products. Additionally, there is a predicted rise in demand for personalized and healthier cereal options. This trend is likely to influence the development of new cereal manufacturing technologies that cater to niche markets and dietary preferences, such as gluten-free or organic cereals.

Furthermore, globalization and digitalization will play crucial roles in shaping the industry landscape in 2024. Breakfast cereal manufacturers are exploring opportunities in emerging markets, leveraging digital marketing strategies to reach new consumer demographics. This includes online platforms and e-commerce channels, where consumers increasingly purchase breakfast cereals directly from manufacturers. As a result, there will be a greater emphasis on optimizing supply chain efficiency and logistics to meet the demands of global markets effectively.

In conclusion, the Breakfast Cereal Machine Factory industry in 2024 is set to experience transformative changes driven by technological advancements, sustainability initiatives, and evolving consumer preferences. Manufacturers who can adapt swiftly to these trends and innovate their production processes accordingly will be well-positioned for growth in the competitive global market.

References

1.Food Engineering Magazine - https://www.foodengineeringmag.com/

2.Food Processing - https://www.foodprocessing.com/

3.Packaging World - https://www.packworld.com/

4.Food Manufacturing - https://www.foodmanufacturing.com/

5.Processing Magazine - https://www.processingmagazine.com/

Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines