- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Company News> Professional Corn Filling Snacks Making Machine With Custom-Design Service

Professional Corn Filling Snacks Making Machine With Custom-Design Service

2023-05-16 15:05:54Introduction of Corn Filling Snacks Making Machine:

The corn filling snacks production line to corn and rice and other puffed grains crushed as the basic raw material, after extrusion puffing maturation molding, powdered metamaterials in the starch tissue denaturation paste, thus more homogenization effect, easier to be digested and absorbed. After sandwiching the core material from the inside adsorbed in the puffed tube wall and oozing, the two blended together, the core material of the cold taste and the exterior puffed cereal warmth to form a strong taste contrast, making it an alternative to puffed food, so the production line processed with the puffed sandwich rice fruit, compared to the traditional non-puffed casual food with a variety of taste, sweet and delicious, melt in the mouth advantage.

In terms of process, the corn filling snacks production line has no noise, dust and other serious pollution.In terms of operation, the corn filling snacks production line covers a small area and is easy to operate, which can reduce the labor cost of users without extra labor.

The whole corn filling snacks production line can automatically complete the production from mixer, screw conveyor, twin screw extruder, core filler,multi-function shaper,hoister, multi-layer oven and flavoring line to the finished product.

Details of the production line:

|

Production capacity |

120-1000kg/h |

|

Electricity supply |

Customised according to your local electricity situation. |

|

Machine details |

1.Stainless steel:201, 304, 316, on request. 2.Electrical components can be ABB, Delta, Fuji, Siemens, famous brands. |

|

Certificates |

CE,GOST,TUV,BV,SGS |

|

Applications |

Corn-filled snacks, chocolate filled bar, rice cake, cereal bar,etc |

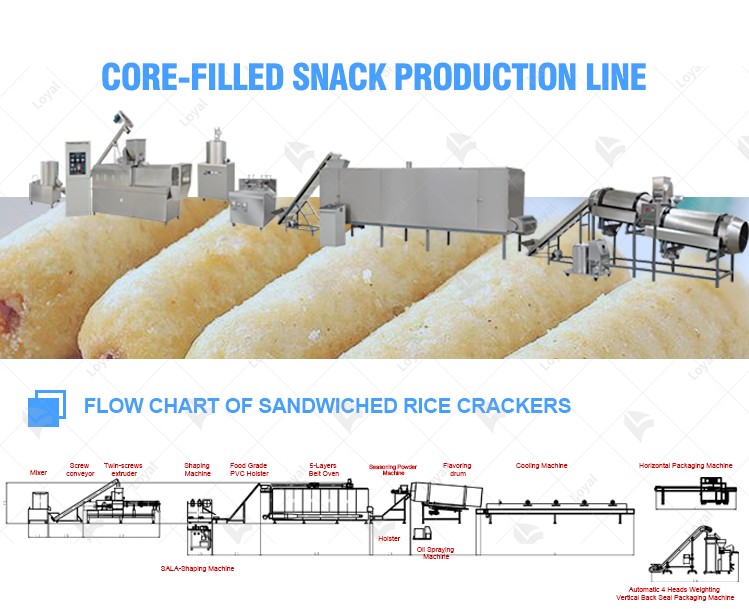

Flow chart of Corn Filling Snacks processing line:

Mixer-Screw Conveyor-Twin Screw Extruder-Core Filler-Multi Function Shaper-Hoister- Multi Layer Oven - Flavoring Line

Features of the Corn Filling Snacks processing line:

1.Productivity:automated system for controlled and stable production on a continuous basis, easy and quick product change, automatic start-up, simple cleaning and maintenance procedures.

2.Economical: low investment, quick results.

3.Environmental protection: moderate output and energy saving.

4.Intelligent control system: PLC control of production to ensure optimum process parameters for each recipe.

5.Automatic lubrication system can reduce power consumption and prolong service life.

Parameters of the Corn Filling Snacks Production Line:

|

Model |

Installed Power (KW) |

Power Consumption (kw) |

Capacity (kg/h) |

Dimension (m) |

|

LY65 Corn Filling Snacks Production Line |

80 |

55 |

120-150 |

21000*1200*2200mm

|

|

LY70 Corn Filling Snacks Production Line |

115 |

95 |

200-250 |

23000*1500*2200mm

|

|

LY85 Corn Filling Snacks Production Line |

170 |

140 |

500-700 |

28000*3500*2200mm |

|

LY90 Corn Filling Snacks Production Line |

230 |

164 |

800-1000 |

29000*2500*3500mm |

Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines