- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Processing> The Development Prospects Of Pet Food And The Introduction Of Pet Food Production Line

The Development Prospects Of Pet Food And The Introduction Of Pet Food Production Line

2021-03-31 11:45:37The diversified trend of pet market demand has also caused its production chain to be rapidly extended, and its food functionality, health, and high value-added trends are also placing higher requirements on related pet food production equipment.

In the past two years, as the social performance and companionship performance of pets gradually emerged, the number of domestic pets kept on the rise. Data show that in 2018, the number of pets in China's cities and towns has reached 73.55 million, of which 56.48 million people have raised dogs and cats in cities and towns. By 2019, the number of pet dogs and cats in cities and towns in China has reached 99.15 million, an increase of 7.66 million from last year only.

At the same time, the pet food market formed around pet breeding continues to expand. Public data shows that in 2018, my country's pet food market reached 170.8 billion yuan, an increase of 27% over 2017; in 2019, the overall consumption scale of my country's urban pet (dog and cat) consumer market reached 202.4 billion yuan, an increase of 18.5% year-on-year.

At the same time, the pet food market formed around pet breeding continues to expand. Public data shows that in 2018, my country's pet food market reached 170.8 billion yuan, an increase of 27% over 2017; in 2019, the overall consumption scale of my country's urban pet (dog and cat) consumer market reached 202.4 billion yuan, an increase of 18.5% year-on-year.

The billion-dollar industry brought about by pet breeding is becoming a new growth point for my country's economy. In addition to market demand, the propelling force for the healthy development of the pet food market is the optimization and upgrading of related production equipment.

The billion-dollar industry brought about by pet breeding is becoming a new growth point for my country's economy. In addition to market demand, the propelling force for the healthy development of the pet food market is the optimization and upgrading of related production equipment.

1. What Are The Steps In The Pet Food Production Line?

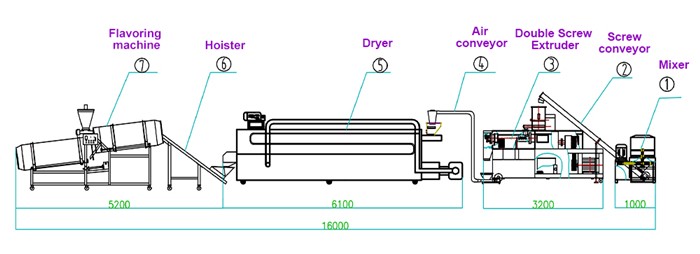

Mixer--- Screw conveyor--- Twin screw extruder--- Air conveyor- The oven--- Flavoring--- Cooling--- Packing

2. How the cat food machine to make the cat food?

1. Mixing all of raw materials (flour, corn flour, rice flour, bone meal, etc.) with. So, water and liquid chemical additives in the mixer.

2. The mixed materials can be conveyed in the stainless steel roller into the feeding machine(feeder) of extruder without any leaking, dusting and pollution. So the cat food quantity and speed is even and stable.

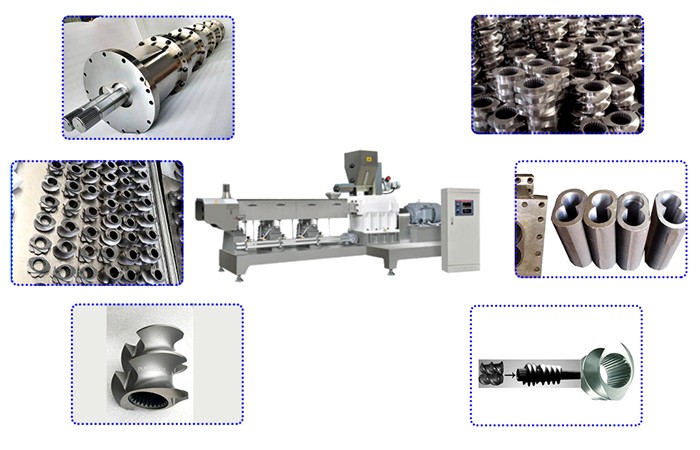

3. First of all, materials enter the pet food extruder machine barrel screw. Secondly, due to the friction between the barrel screws, there will be a high-temperature and high-pressure effect, resulting in material ripening. Thirdly, all of materials are pushed to the discharge port of the front section of the barrel. Finally, through the die holes of different shapes on the die to extrude and expand the corresponding shape.

4. Then hoister conveys the food into the dryer, the height of the hoister depends on the dryer.

5. The dryer controlled by control box, temperature range 0-200ºC. And then inside is the stainless steel mesh net. So the dying time is adjustable according to speed. Also, it is stainless steel double layer mesh net. What’s more, the dryer have the different layers, normally it is the single layers, like 3layers , 5 layers , etc.

6. After baking, the moisture content is about 10%. Also, we can store it for more than one year without adding any preservatives. Then, oil spray need to add fat to dry food and is an important part of cat food nutrition. Finally, spraying the configured minerals and vitamins and other substances on the dog feed just after the spraying.

The diversified trend of pet market demand has also caused its production chain to be rapidly extended, and its food functionality, health, and high value-added trends are also placing higher requirements on related pet food production equipment. Relevant equipment manufacturers must pay close attention to market demand, innovate processing technology, improve equipment production stability, and improve the performance of core equipment such as puffing machinery and equipment, so as to enhance the quality of pet food.

Pet Food Production Line

Pet Food Production Line Dog Treat Biscuit Making Machine

Dog Treat Biscuit Making Machine Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines